Unloading off-circuit tapping switch

A tap changer and unloading technology, applied in the direction of transformer/inductor coil/winding/connection, transformer, electrical components, etc., can solve the problem of cage switch insulator rigidity improvement and limited protection, switch volume transformer volume increase, transformer Increased effective space and other issues to achieve the effect of enhancing work reliability, reducing switch volume and improving insulation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

[0014] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

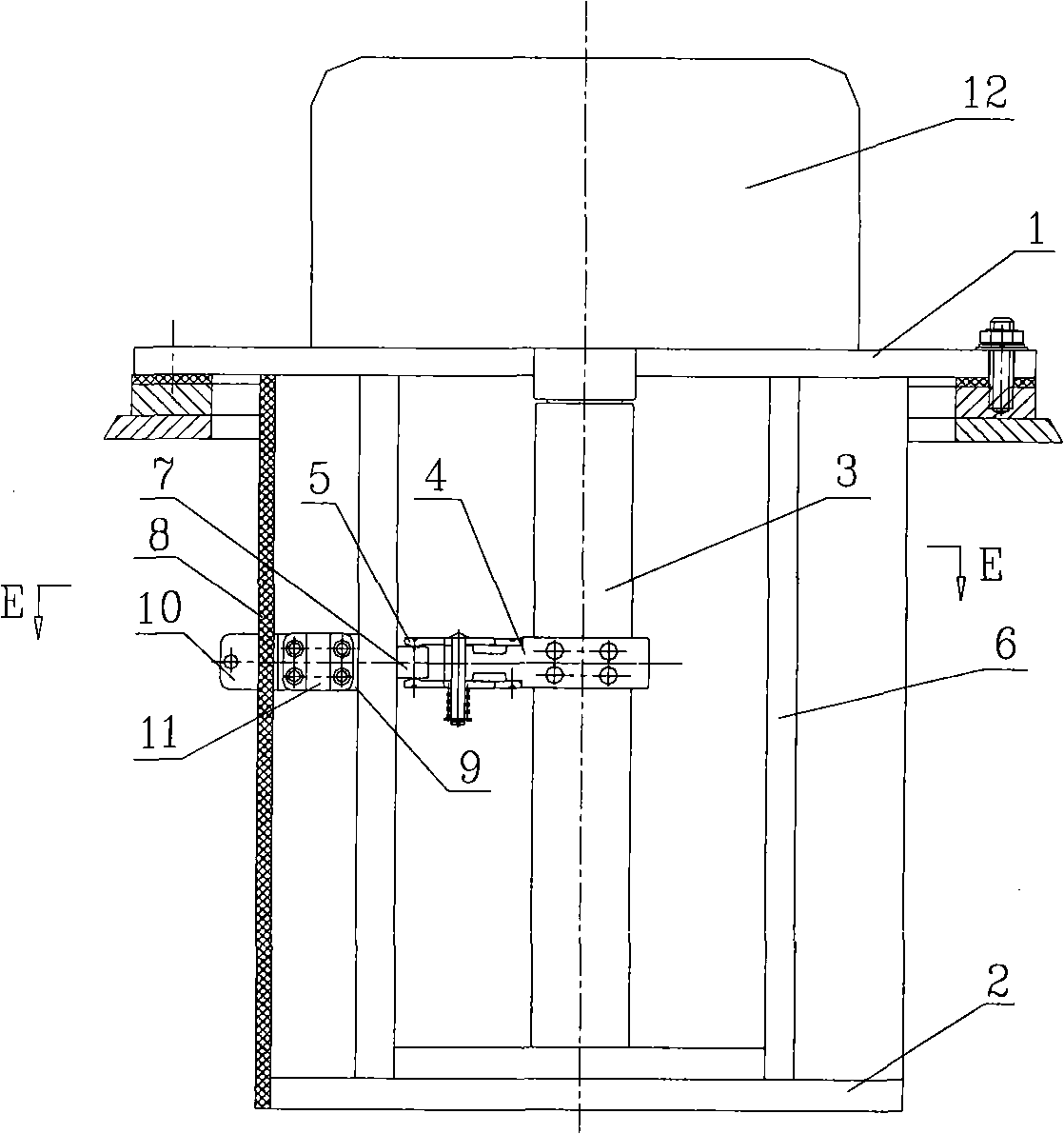

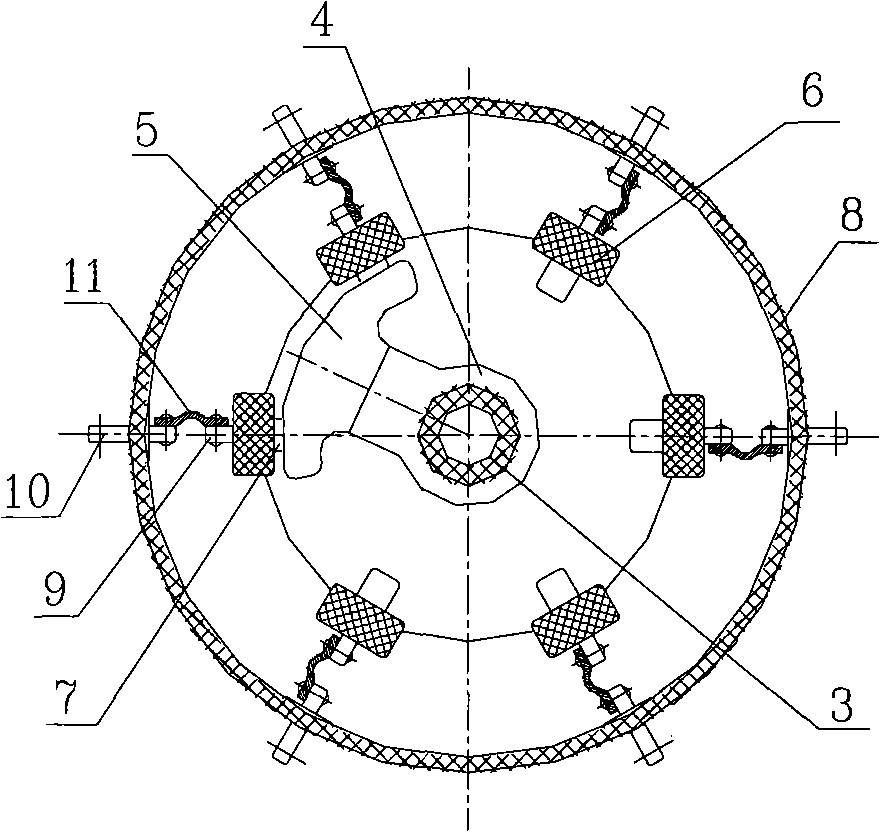

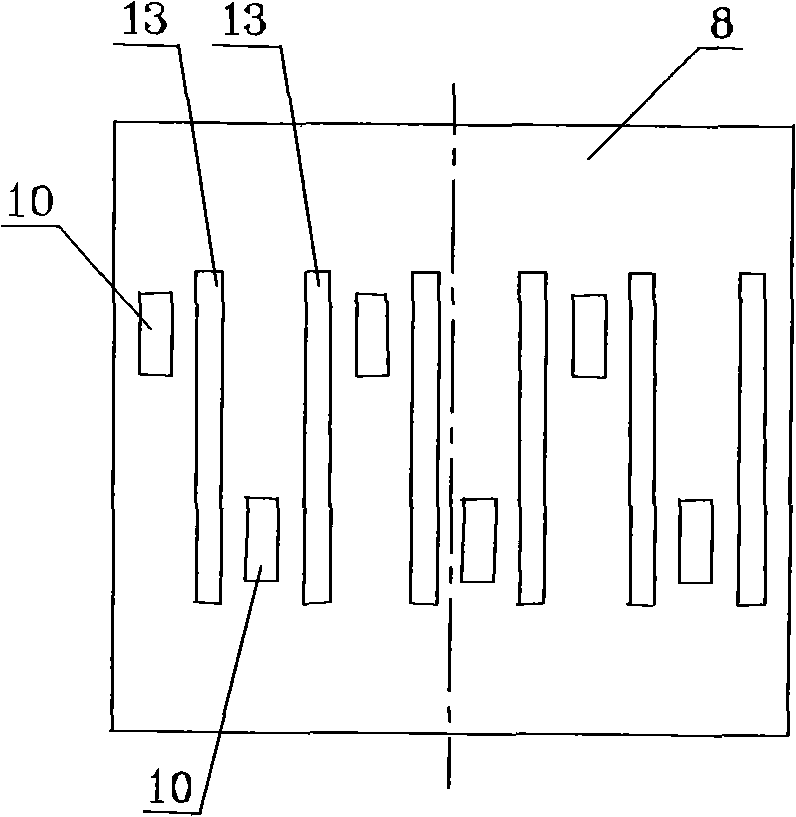

[0015] Examples of the present invention are figure 1 , 2 , 3, it is a single-phase five-speed non-excitation tap changer, including an upper support 1, a lower support 2, and a rotating shaft 3 is installed in the upper and lower support, and the rotating shaft 3 is connected to the operating mechanism 12. On the rotating shaft A support 4 and a moving contact assembly 5 are installed, and an insulator 6 is connected between the upper and lower supports. The insulator is a cage-shaped insulator, which is composed of 6 insulating rods arranged at intervals in the circumferential direction; the inner side of the insulator is installed The first layer has a static contact 7 corresponding to the moving contact assembly, the rear end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com