Laser device with pendulous press roller

一种激光装置、激光束的技术,应用在激光焊接设备、制造工具、焊接设备等方向,能够解决降低焊缝质量等问题,达到简化焊接作业的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

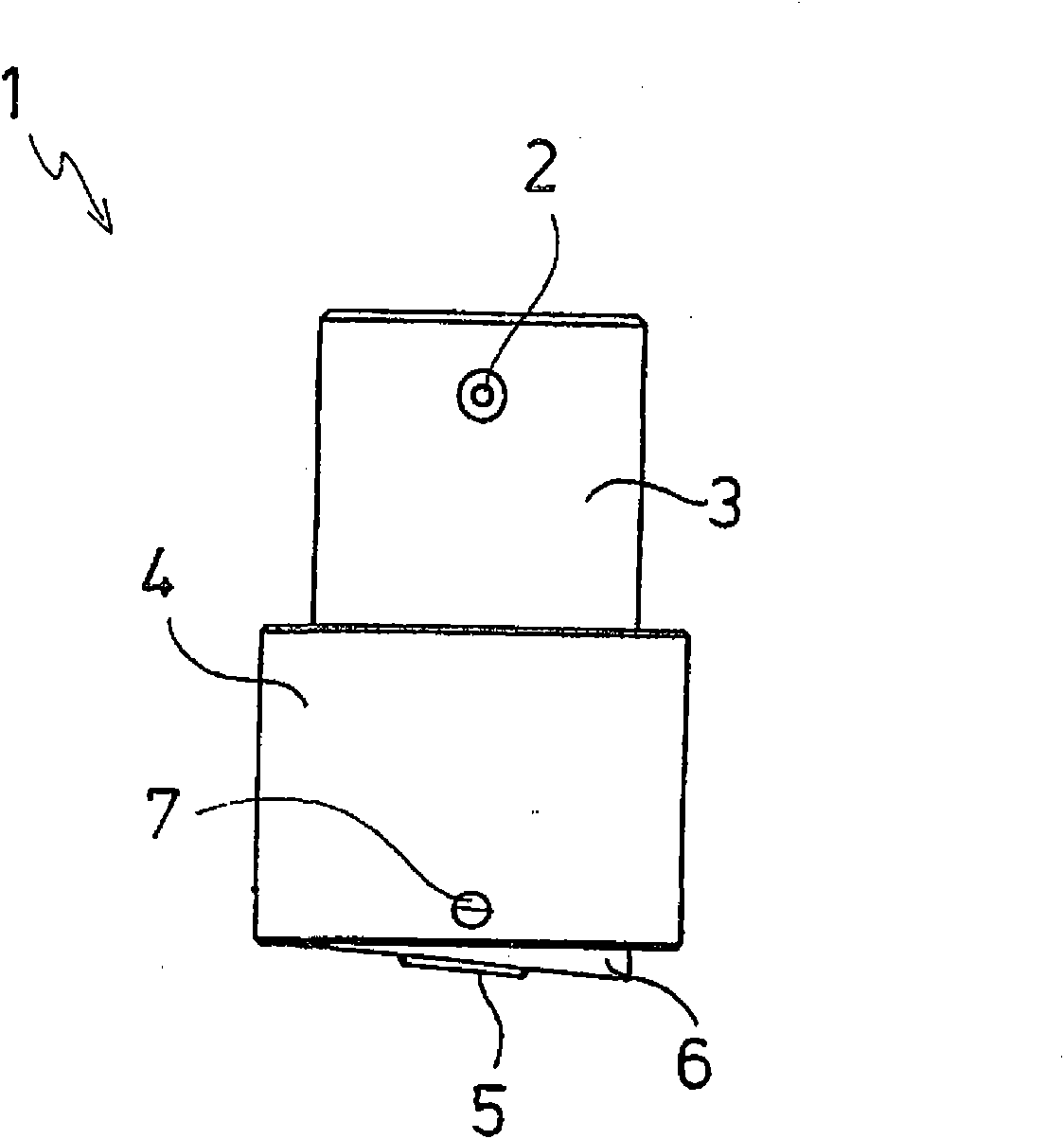

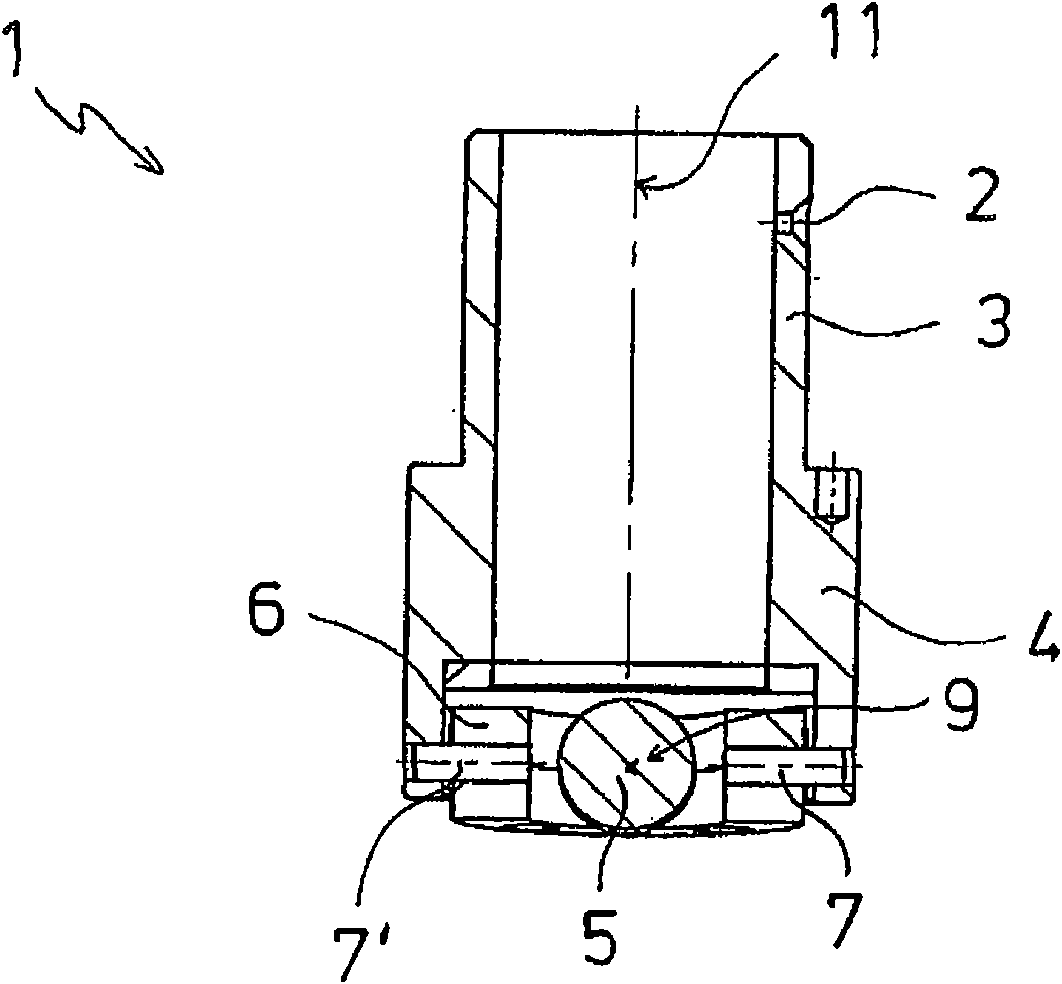

[0020] figure 1 A holding tube 1 of a processing head (not shown in the drawing) of a laser device according to the invention is shown. The holding tube 1 is designed as a stepped hollow cylinder and can be releasably fastened to the processing head by means of a fastening device 2 after it has been inserted with the upper connecting section 3 into the cavity of the processing head. Furthermore, a focusing device is provided in the processing head, which shapes and guides the laser beam incident from the laser source.

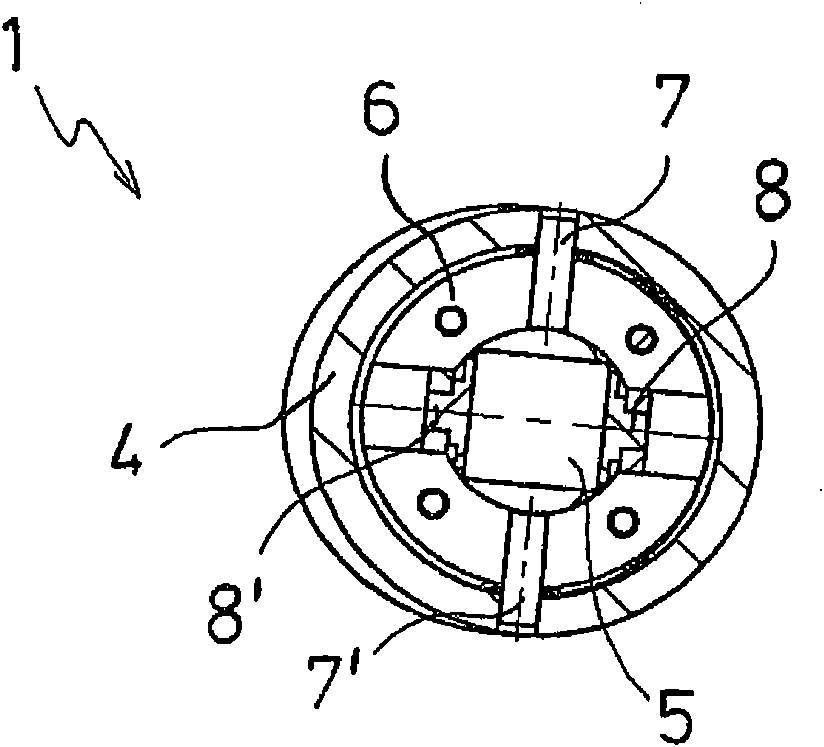

[0021] On the lower fastening section 4 of the holding tube 1 , which is directly connected with an enlarged diameter to the connecting section 3 , a cylindrical lens 5 is movably connected to the holding tube 1 via a receiving ring 6 . The holding barrel 1 and the receiving ring 6 are made of metal. The cylindrical lens 5 is permeable for the laser beam (not shown in the drawing) and consists of glass or a transparent plastic material.

[0022] figure 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com