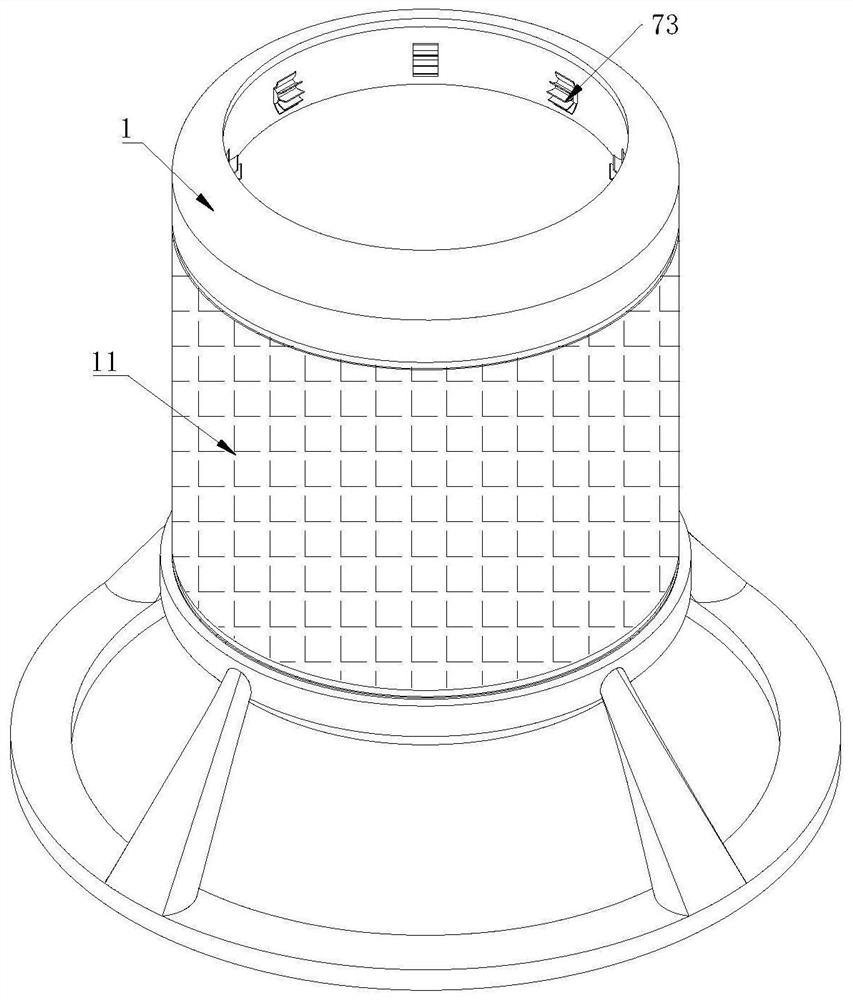

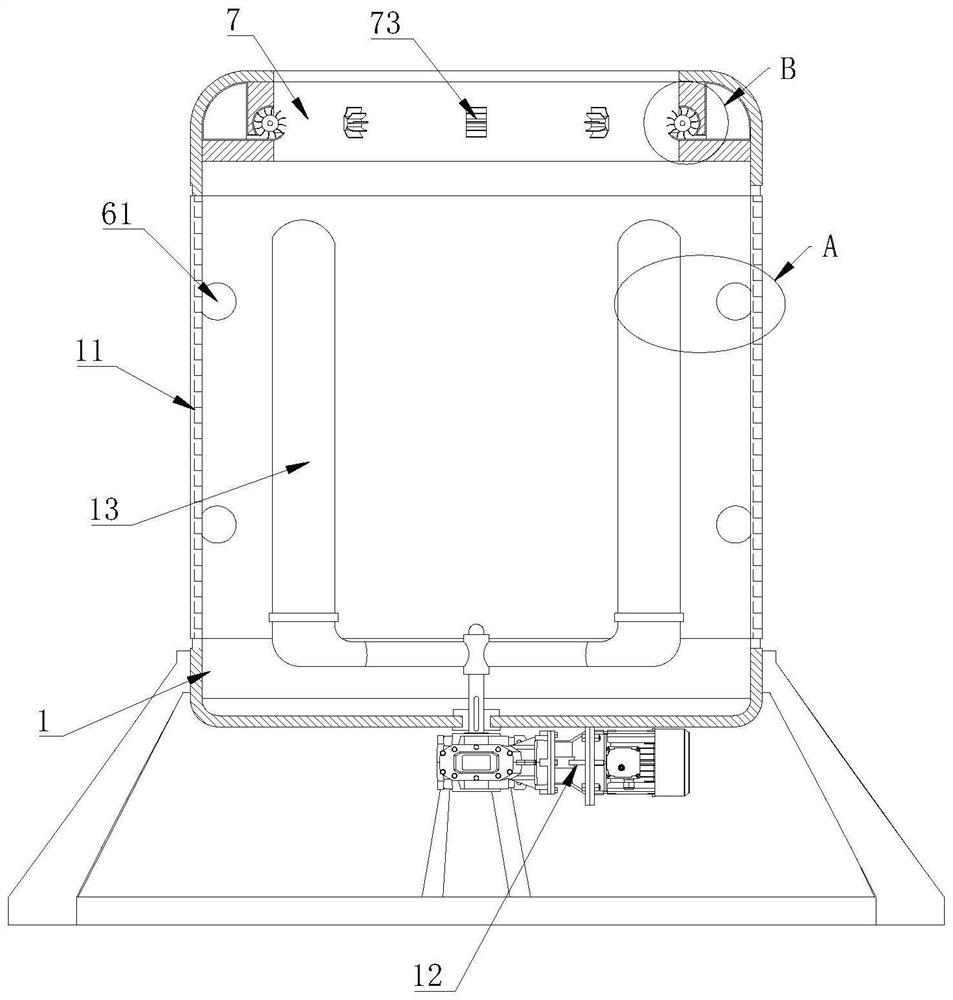

High-strength automatic casting equipment for rear axle head

A casting equipment, high-strength technology, used in casting equipment, heat treatment equipment, metal processing equipment and other directions, can solve the problem of uneven cooling speed of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

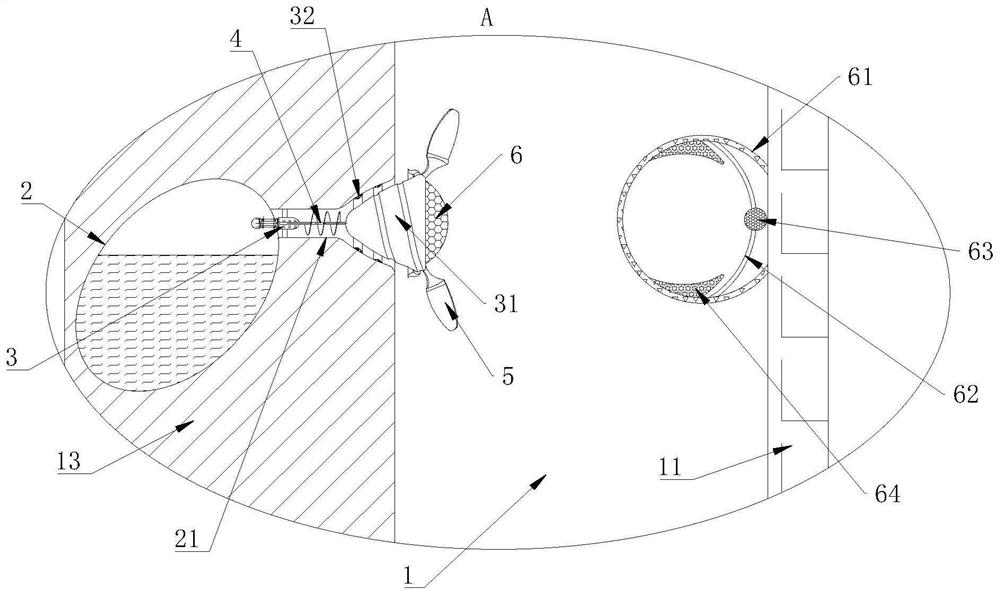

Examples

Embodiment 2

[0043] see Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention, a fixed seat 93 is fixed on the side wall near the end of the stressed blade 73; a brush is fixed on the bottom of the fixed seat 93 94; when the stressed blade 73 rotates, the brush 94 will rub against the inner side wall of the output end of the water storage tank 71, and the dilute hydrochloric acid on the inner side wall of the output end of the water storage tank 71 will be swept away, reducing the amount of water on the inner side wall of the output end of the water storage tank 71. In the case of reducing the waste of dilute hydrochloric acid, the dilute hydrochloric acid attached to the brush 94 can also be thrown to the inside of the cooling chamber 1 when the brush 94 leaves the water storage tank 71 ports.

[0044]Working principle: When in use, during the casting process, the components that need to be normalized are hoisted by the sling, and then put into the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com