An automated factory that can be monitored remotely

A remote monitoring and remote monitoring system technology, applied in the field of automatic and remote monitoring factories, can solve the problems of narrow application range, high cost, single function, etc., and achieve the effect of ensuring accurate positioning, ensuring stability and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

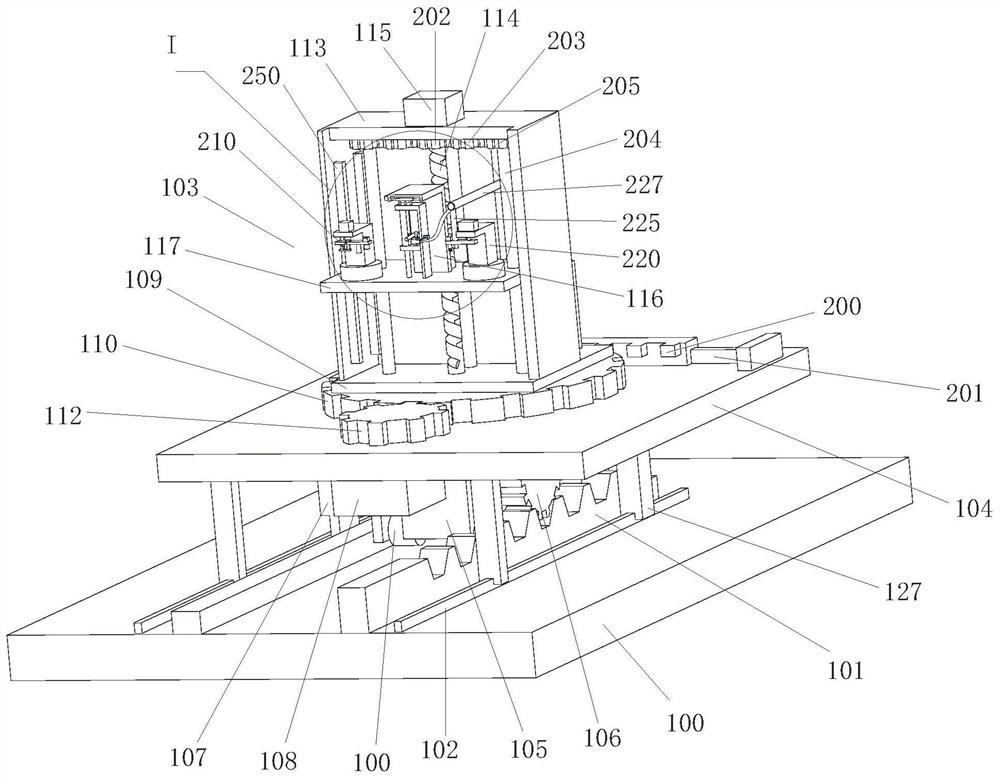

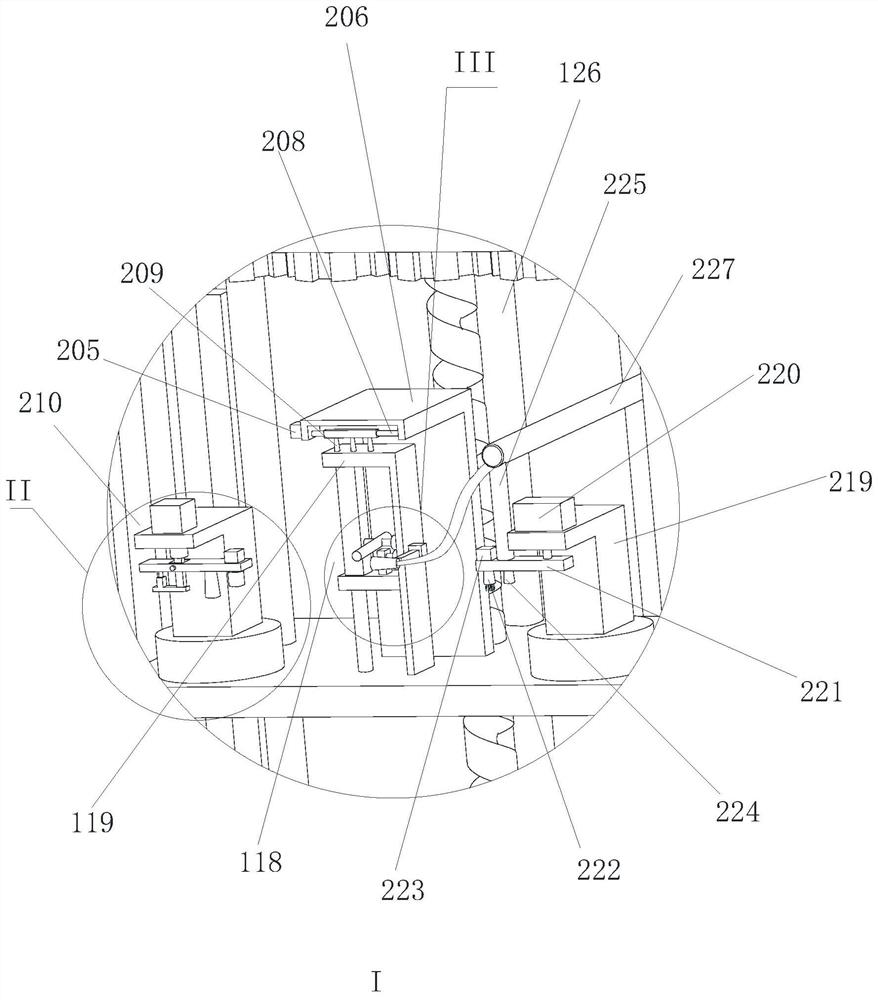

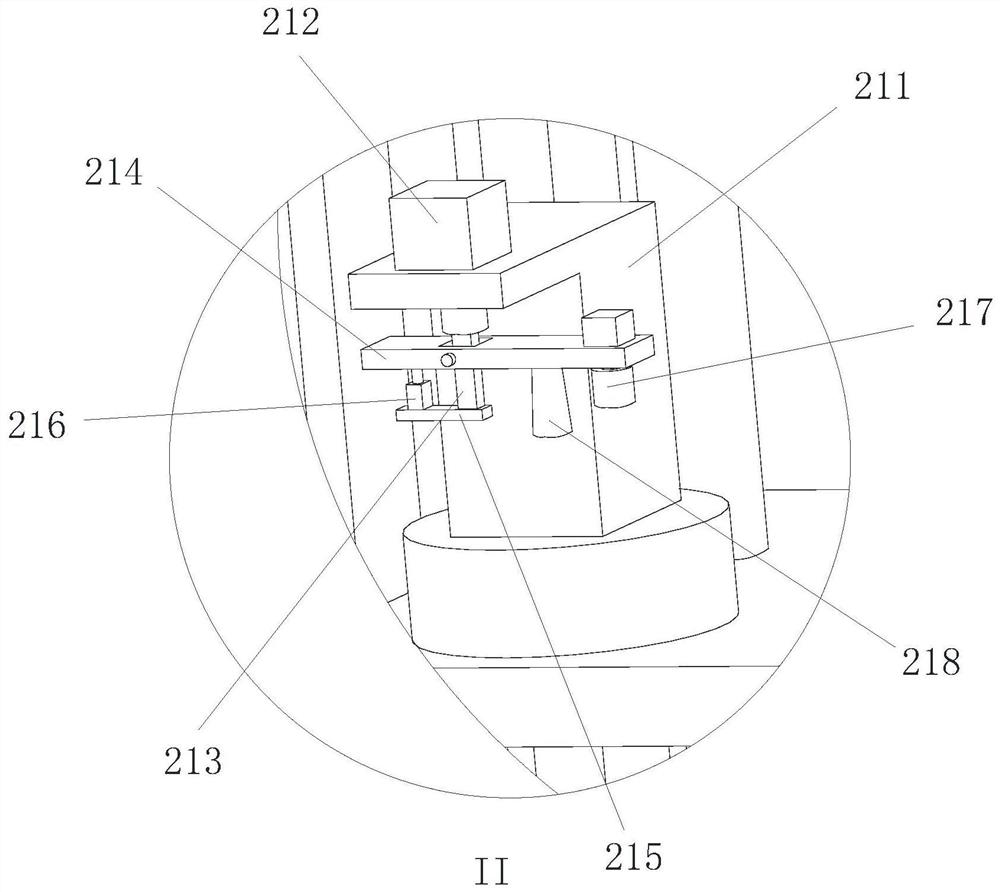

[0024] Such as Figure 1 to Figure 5 and Figure 7 As shown, an automated and remotely monitored factory includes a remote monitoring system and an industrial router. The industrial router communicates with the welding production line in the factory and collects real-time data information of the production line equipment and transmits the information to the remote monitoring system; The welding production line equipment includes a robot main body for automatic production line welding and a control system for controlling the movement of the robot main body. The robot main body includes a base plate 100 on which a first rack 101 and a first guide rail group 102 are arranged. The bar 101 and the first guide rail group 102 are provided with a welding manipulator 103 which moves linearly along the first guide rail group 102; On a guide rail group 102, the lower end surface of the welding platform 104 is provided with a walking power group, the walking power group includes a first ...

Embodiment 2

[0031] Such as Figure 1 to Figure 7As shown, the difference between this embodiment and Embodiment 1 is that a small wheel set is provided under the bottom plate 100, the small wheel set includes a driving wheel set 140 and a steering wheel set 141, and the driving wheel set 140 includes a driving wheel 142, the drive wheel 142 is connected by setting the drive shaft 143, the drive shaft 143 is provided with the first drive gear 144, the lower end surface of the base plate 100 is provided with the drive motor 145, the drive motor 145 is fixedly connected with the base plate 100, and the drive motor 145 is connected with the first Two driving gears 146, the first driving gear 144 meshes with the second driving gear 146, the driving motor 145 drives the driving wheel 142 to rotate by driving the second driving gear 146, wherein the axis of the driving shaft 143 is perpendicular to the straight line where the first guide rail group 102 is located ; The first guide shaft 126 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com