Extra-huge size engineering all-steel radial tire three-dimensional wrapping and attaching mechanism

A technology for radial tires and engineering, which is applied in the field of three-dimensional wrapping mechanisms for extra-large all-steel engineering radial tires, can solve the problems of prone backlash, uneven stretching tension of rubber strips, and low accuracy, and achieve slow transition stretching problems, ensuring process precision requirements, and improving the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

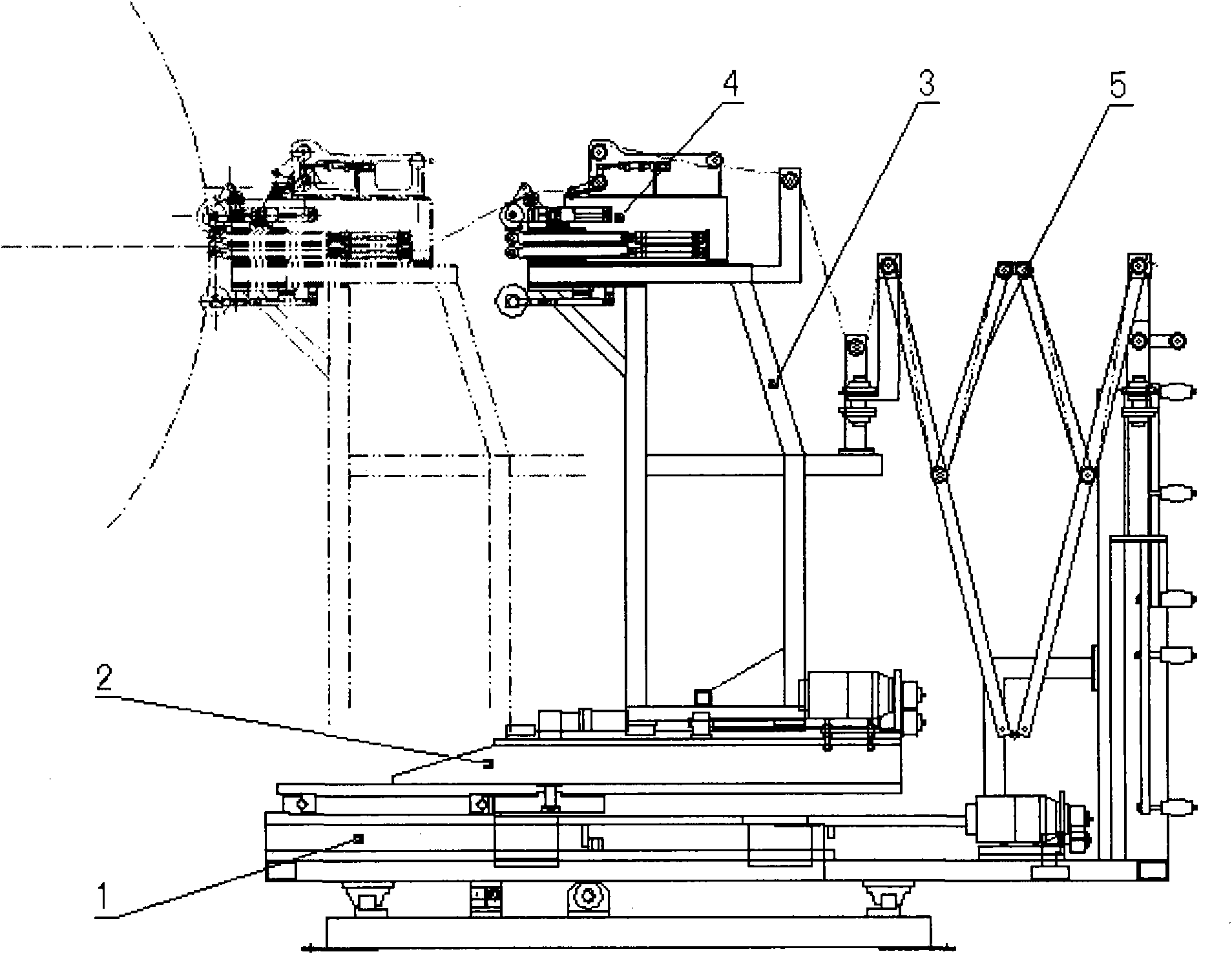

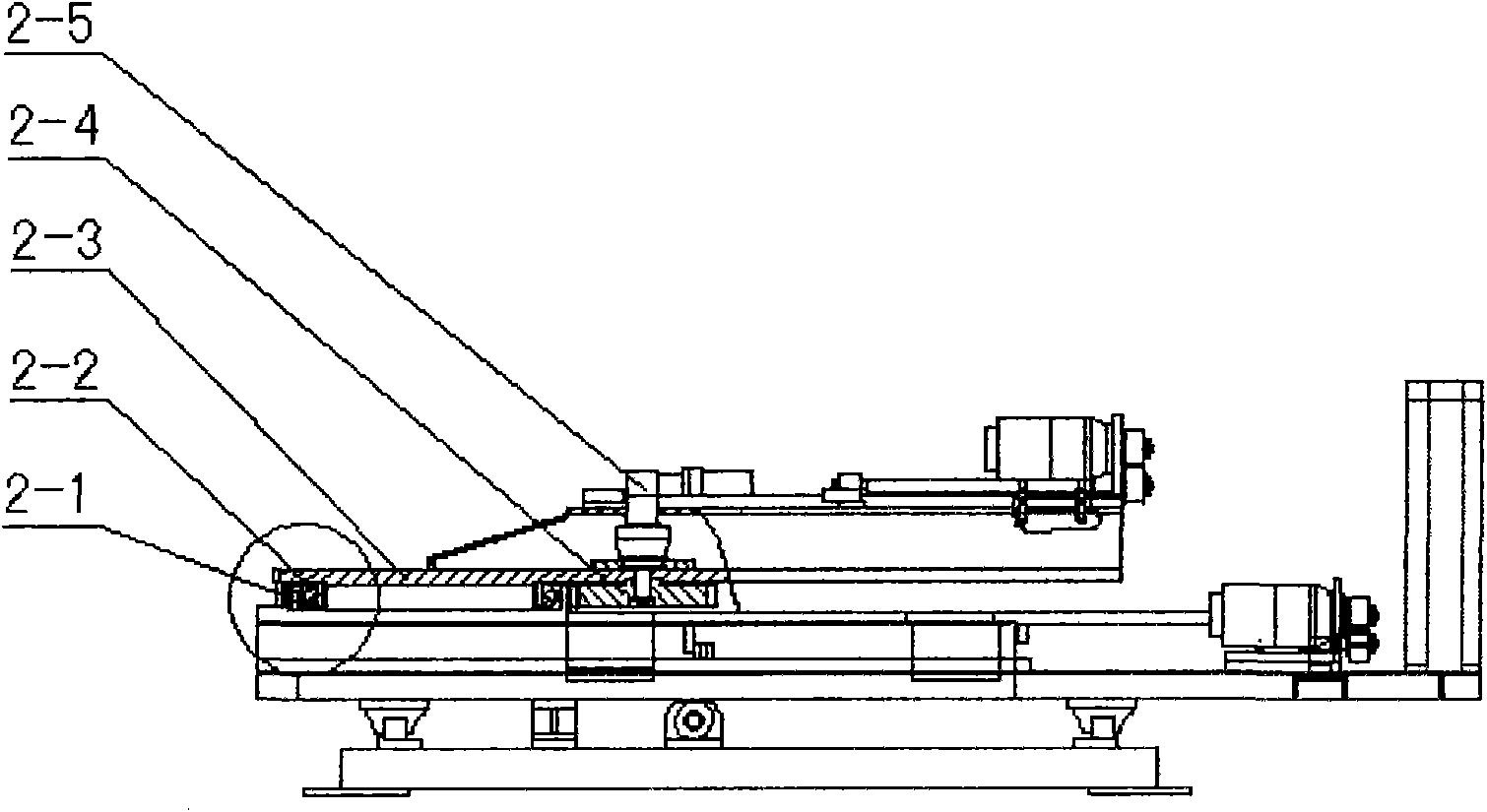

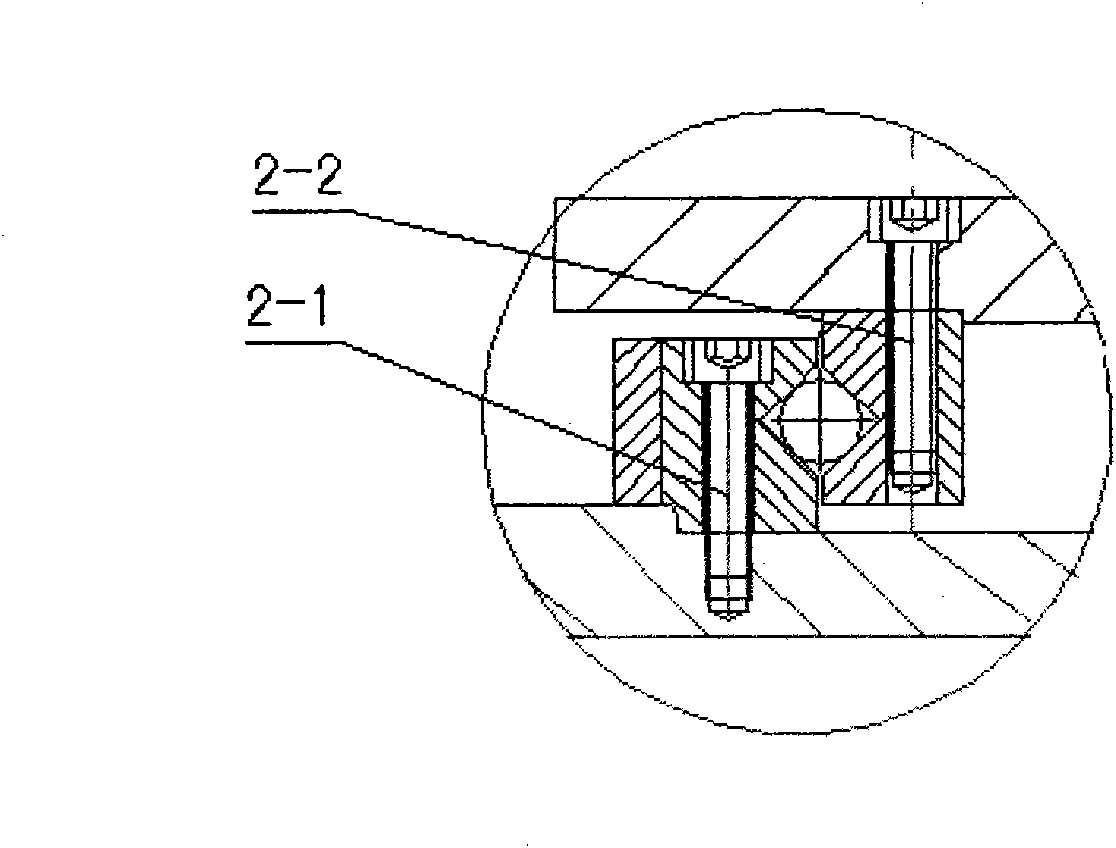

[0017] See figure 1 , figure 2 with image 3 , a three-dimensional wrapping mechanism for extra-large all-steel OTR tires provided by the present invention is composed of a moving base 1, a rotary mechanism 2, a bracket 3, a wrapping device 4 and a bracket 5, wherein the wrapping device 4 is fixedly connected to On the bracket 3, the bracket 3 is movably connected to the rotary mechanism 2, and the rotary mechanism 2 is connected to the moving base 1 in a rotatable manner. The bracket 5 is placed according to the process requirements, and is used for buffering the stretching of rubber strips. Its output end is set at On the bracket 3; the slewing mechanism 2 is composed of an outer gear ring centering track 2-1, a positioning and rotating inner ring 2-2, a slewing mechanism support plate 2-3, a slewing drive servo motor 2-5 and a slewing drive gear 2-4, The outer gear ring centering track 2-1 is fixedly installed on the upper plane of the moving base 1, and the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com