Intelligent three dimensional microgravity air feet

A microgravity and air-sufficiency technology, which is used in space navigation equipment, simulation devices for space navigation conditions, transportation and packaging, etc., can solve the problems of complex truss mechanism, affect the test accuracy, and occupy a large space, and achieve flexible test methods. , the process is simple, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

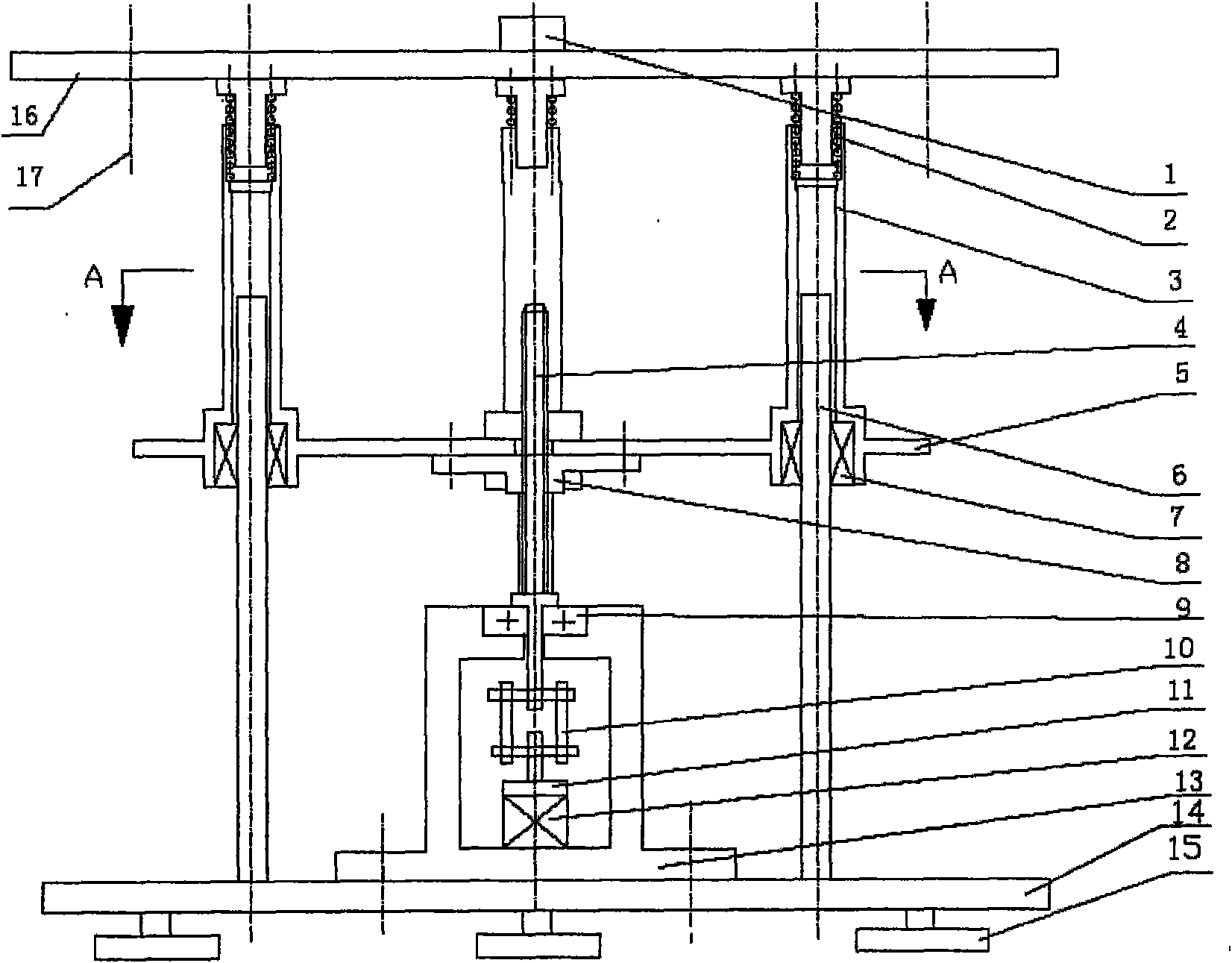

[0015] The following is a detailed description of the creation examples of the present invention in conjunction with the accompanying drawings.

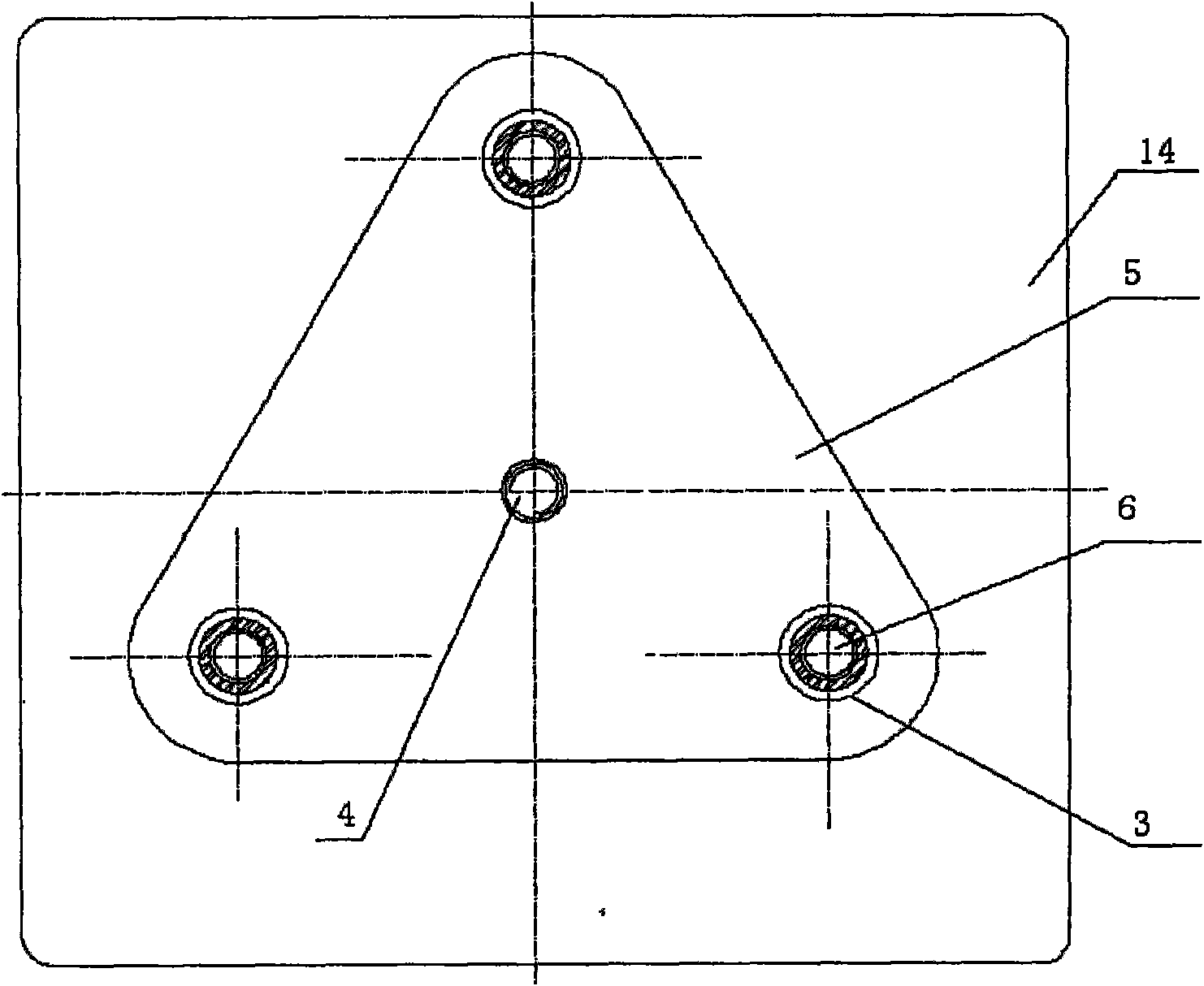

[0016] Three-dimensional microgravity intelligent air foot, including air foot 15, three air feet 15 adjacent to each other at an angle of 120° are uniformly installed on the lower side of the support plate 14; the shell 13 and three guide rods 6 are assembled on the support plate 14 On the side, three guide rods 6 are located on the outer side of the housing 13, and the three guide rods 6 are adjacent to each other at an angle of 120°; the bottom and the upper part of the housing 13 are respectively equipped with a servo motor 12 and a thrust bearing 9, and the thrust A shaft coupling 10 and a speed reducer 11 are arranged between the bearing 9 and the servo motor 12. The power input shaft and the output shaft of the speed reducer 11 are respectively connected with the power output shaft of the servo motor 12 and the shaft coupling 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com