Hydraulic support double-telescopic upright post

A hydraulic support, double-telescopic technology, applied in the direction of pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of broken cylinder bottom, falling off, etc., to prolong the service life, reduce impact stress, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

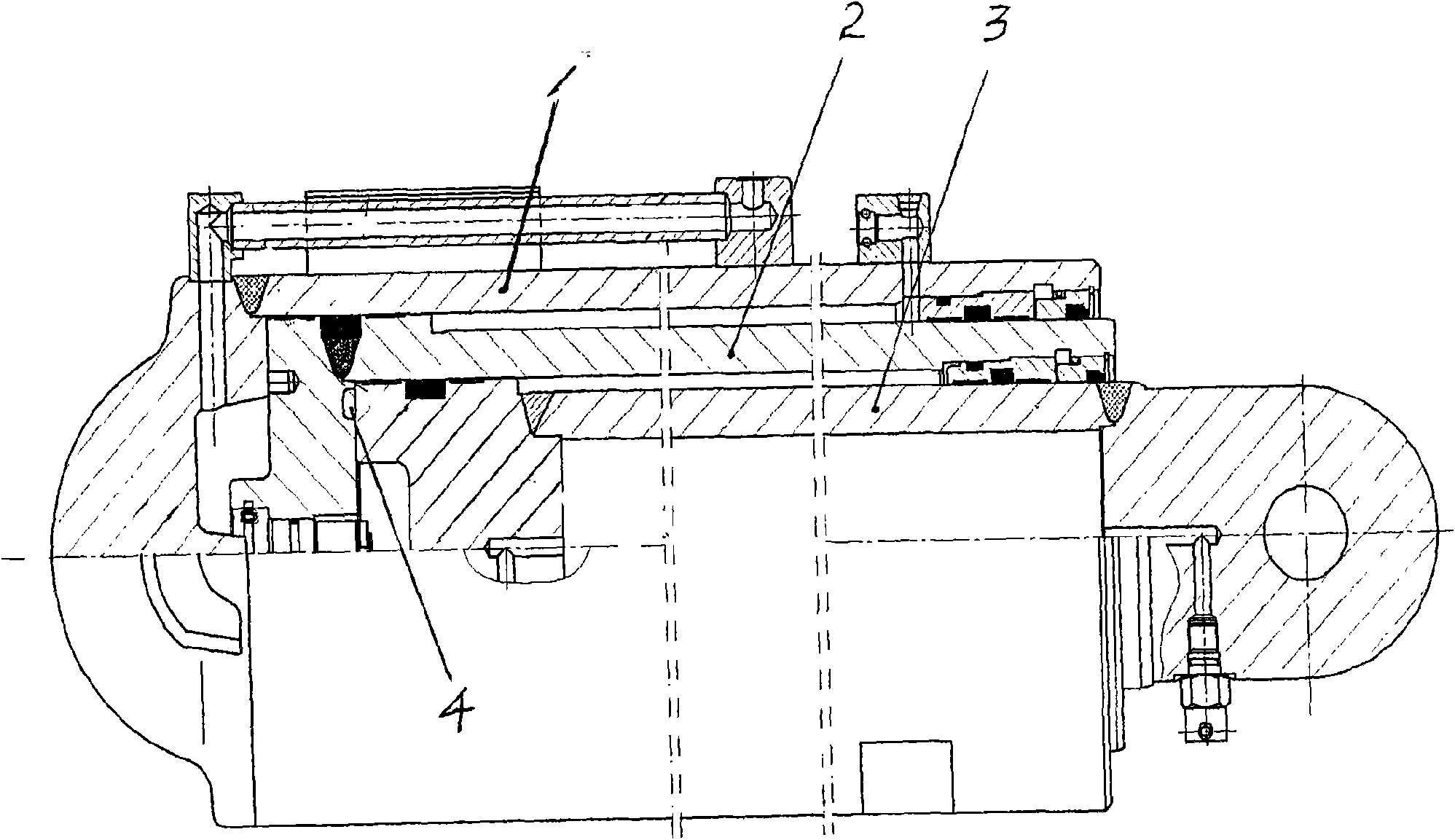

[0008] Since the outer cylinder body 1 and the middle cylinder body 2 are similar in structure, the existing problems are basically the same, and the problem of high stress concentration in the gap of the middle cylinder body 2 is particularly prominent, and the middle cylinder body 2 is taken as an example for further description.

[0009] As shown in the figure, the hydraulic support double-telescopic column of the present invention includes an outer cylinder body 1, a middle cylinder body 2 arranged in the outer cylinder body 1, and a movable body arranged in the middle cylinder body 2. Cylinder 3; the middle cylinder body 2 is formed by welding the middle cylinder bottom 7 and the middle cylinder barrel 6 provided with a joint seam; the cylinder bottom 7 of the middle cylinder body 2 is located inside the joint seam for stress Released ring groove 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com