Connected paired angular contact bearing

A bearing and diagonal technology, applied in the direction of rolling contact bearings, bearings, connecting components, etc., can solve the problems of bearing service life, large instrument reading errors, bearing instability, etc., to achieve accurate power transmission, reduce reading errors, Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

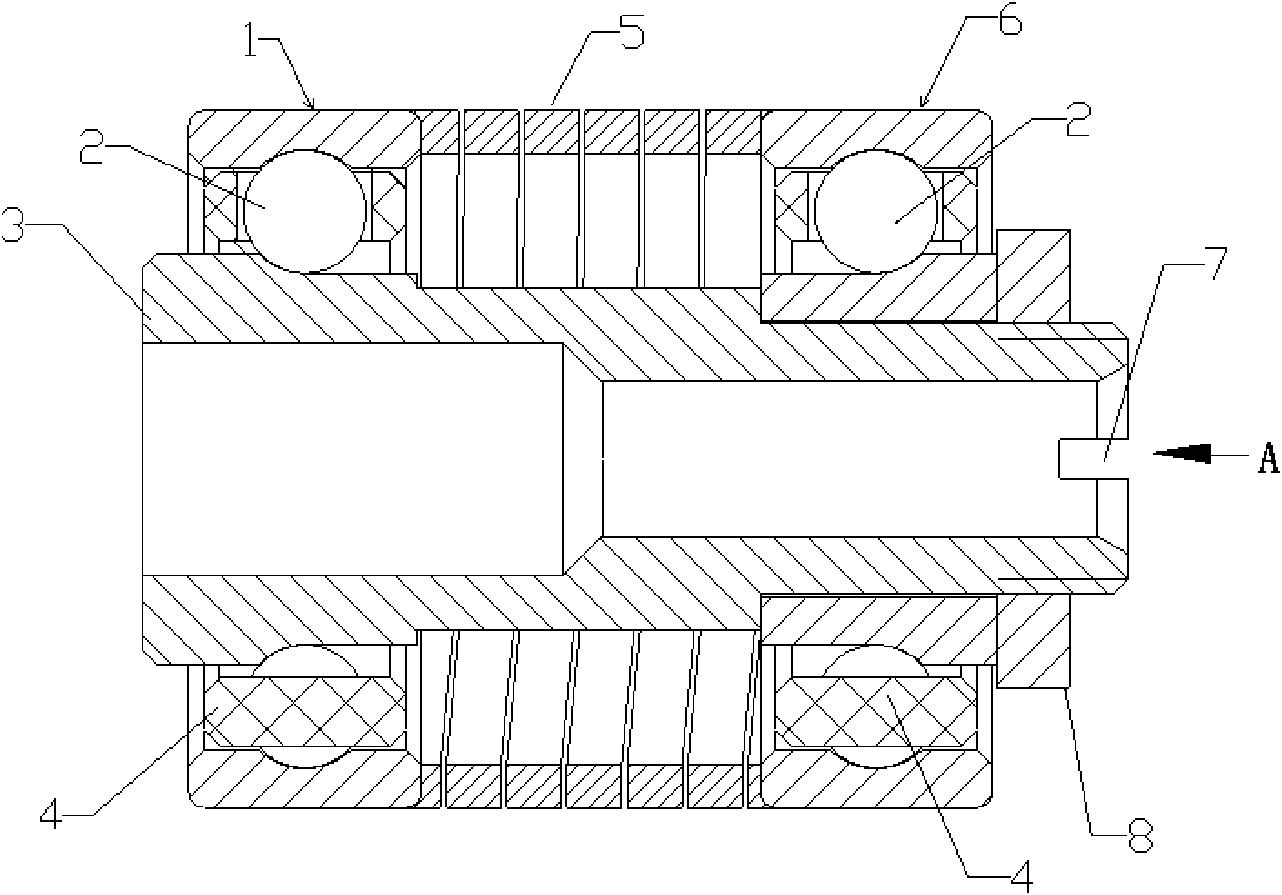

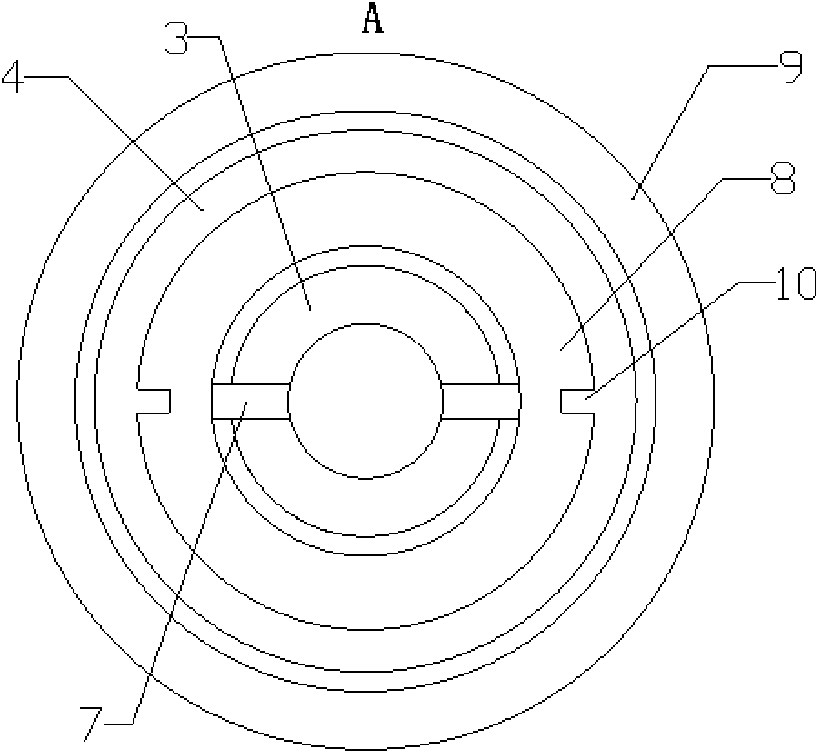

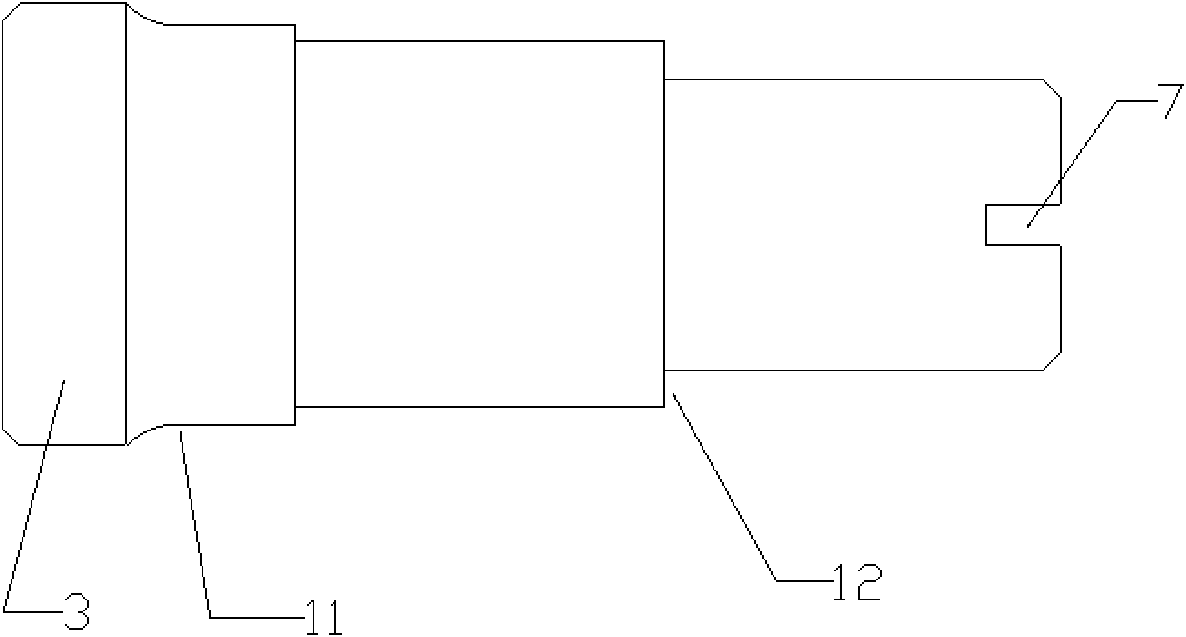

[0019] See attached figure 1 , 2 3. The structure of the diagonal contact bearing of the conjoined set of the present invention includes a rotating shaft 3, a bearing A1 and a bearing B2. The two bearings are sleeved on the rotating shaft 3 side by side with a gap between them. The rotating shaft 3 is provided with two pairs A positioning element for axial positioning of the bearing. These two bearings are angular contact bearings, and the steel balls 2 in them are arranged opposite to the contact angle of the inner ring raceway. A spacer is provided on the outer circumference of the rotating shaft 3, and the spacer is located between the two bearings and is used to separate the two bearings.

[0020] The spacer is a spring 5, and the spring 5 is made of spring steel. The cross-sectional surface of the spring steel bar is rectangular, and the size of the spring steel bar along the axial direction of the spring 5 is larger than the size along the radial direction of the spring 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com