Method for monitoring thickness of metal plating layer on surface of plated part

A technology of surface metal and coating thickness, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of long test time, complex test process, high requirements for electron microscope performance, etc., and achieve the effect of accurate and reliable monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is used to illustrate the method of the present invention for monitoring the coating thickness on the surface of a plated piece.

[0036] Instrument: JSM-5610LV scanning electron microscope (SEM) produced by Japan JEOL Company

[0037] QUEST energy spectrometer (EDS) produced by American NORAN company

[0038]Test Conditions:

[0039] Scanning electron microscope: accelerating voltage 14KV, beam spot 35nm, load current 70μA, working distance 9mm, magnification 10000 times, select scan3 to scan.

[0040] QUEST energy spectrometer: live time is less than 100 seconds, dead time is more than 25 seconds, ZAF correction, data collection time is 56 seconds, pixel points are 128×128, and the collection time of each pixel point is 0.03 seconds.

[0041] Instrument data processing software: SpectraPlus

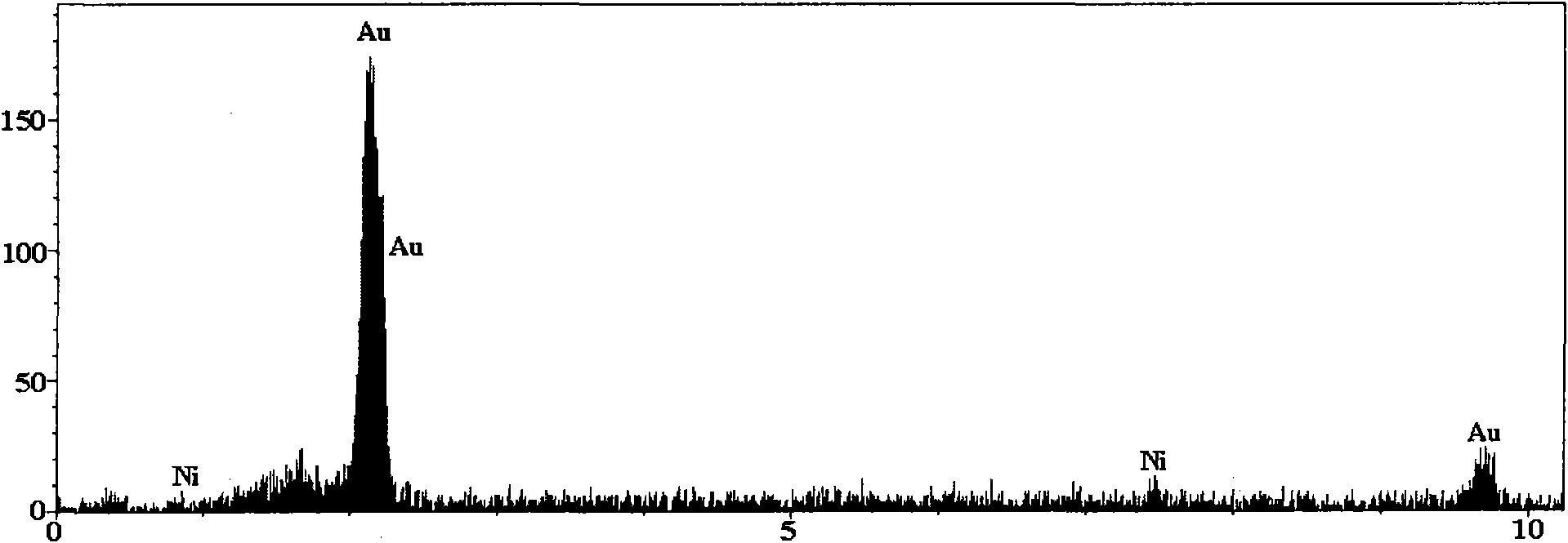

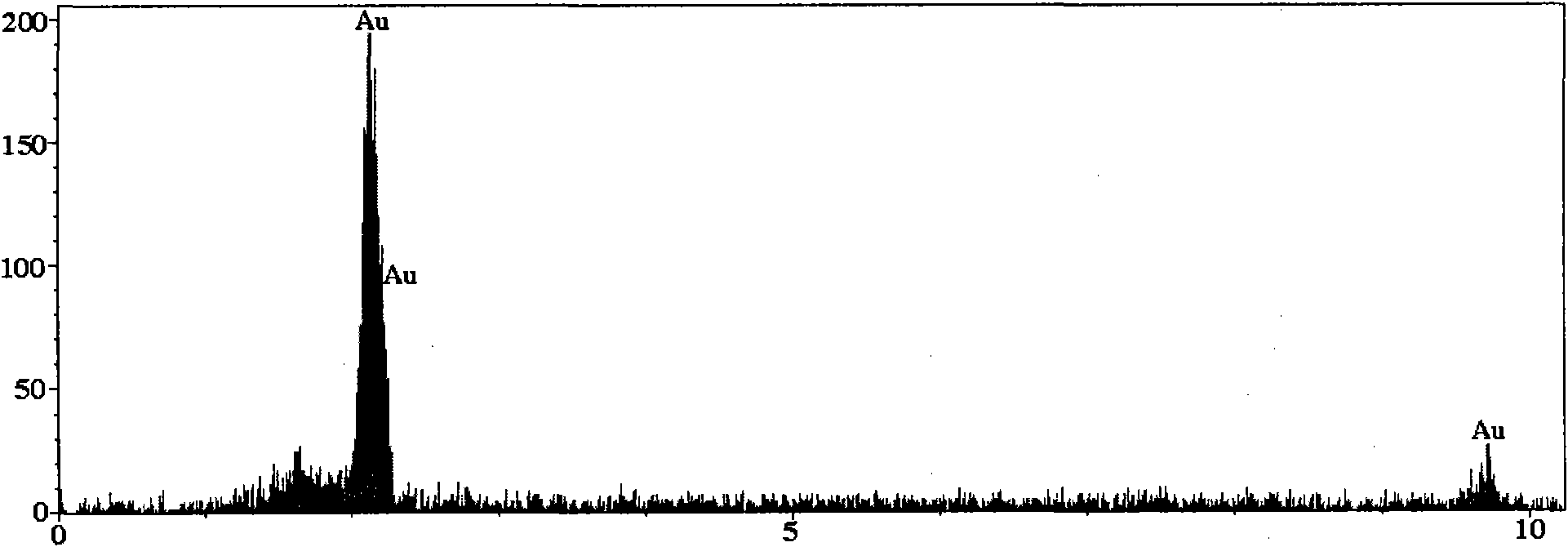

[0042] The base material of the plated part is Cu, and Ni and Au are plated on the base material in turn, the thickness of the Ni layer is 4 μ m, and the Au is...

Embodiment 2

[0045] This embodiment is used to illustrate the method of the present invention for monitoring the coating thickness on the surface of a plated piece.

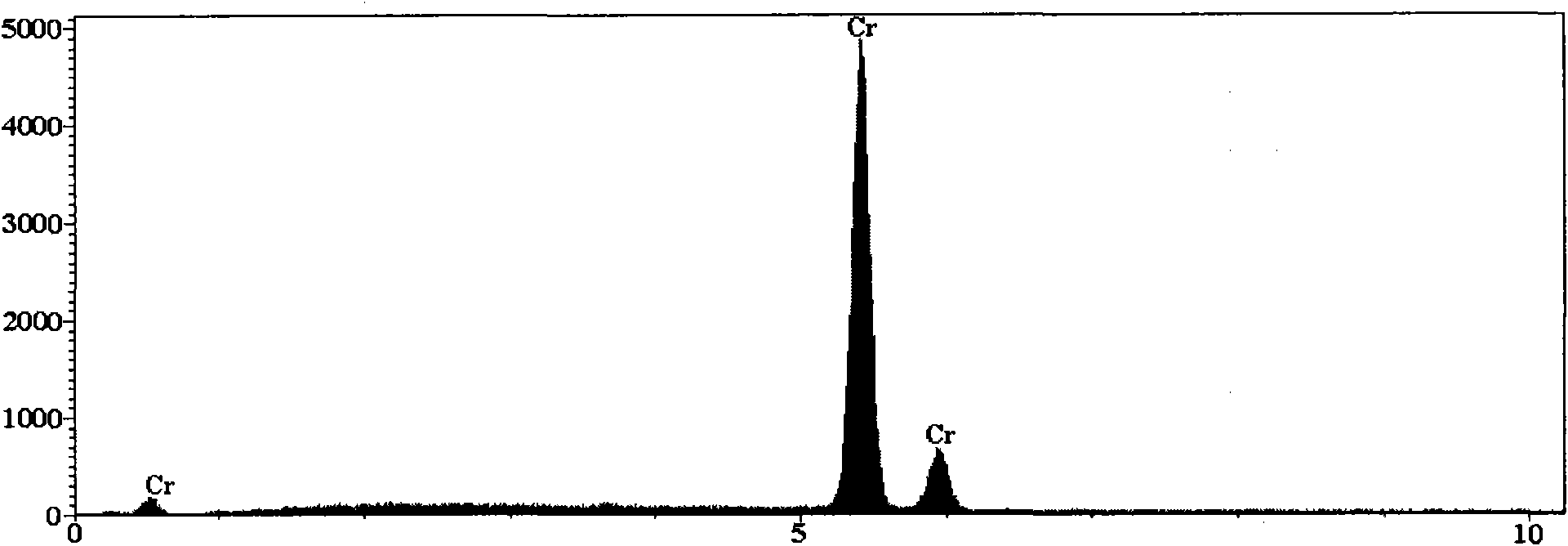

[0046] According to the same method as in Example 1, the difference is that the substrate is plated with Cr and Al in sequence, the thickness of the Cr layer is 5 μm, and the Al is located on the surface, and the accelerating voltage is 20KV. The test results are: 0.3 μm, 0.38 The characteristic peaks of Cr and Al appear in the spectra of standard samples of μm, 0.43 μm, 0.48 μm, 0.5 μm, 0.53 μm, 0.56 μm, 0.6 μm, 0.63 μm and 0.7 μm, among which, the EDS spectrum of the 0.7 μm standard sample Such as image 3 shown. Only the characteristic peaks of Al appear in the spectra of 0.73 μm and 0.8 μm standard samples, among which, the EDS spectra of 0.73 μm standard samples are as follows Figure 4 shown. Such test results indicate that the currently set accelerating voltage can be used to monitor whether the thickness of the sur...

Embodiment 3

[0048] This embodiment is used to illustrate the method of the present invention for monitoring the coating thickness on the surface of a plated piece.

[0049] Instrument: JSM-5610LV scanning electron microscope (SEM) produced by Japan JEOL Company

[0050] QUEST energy spectrometer (EDS) produced by American NORAN company

[0051] Fixed test conditions:

[0052] Scanning electron microscope: working distance 9mm, beam spot 35nm, load current 70μA, magnification 10000 times, select scan3 to scan.

[0053] QUEST energy spectrometer: live time is less than 100 seconds, dead time is more than 25 seconds, ZAF correction, data collection time is 70 seconds, pixel points are 128×128, and the collection time of each pixel point is 0.03 seconds.

[0054] Test conditions that need to be adjusted: Accelerating voltage

[0055] Instrument data processing software: SpectraPlus

[0056] The plated parts are copper-clad laminates (referred to as copper-clad laminates), and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com