Combined sampling valve

A sampling valve and combined technology, applied in sampling devices, sliding valves, valve devices, etc., can solve problems such as increasing the initial construction cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

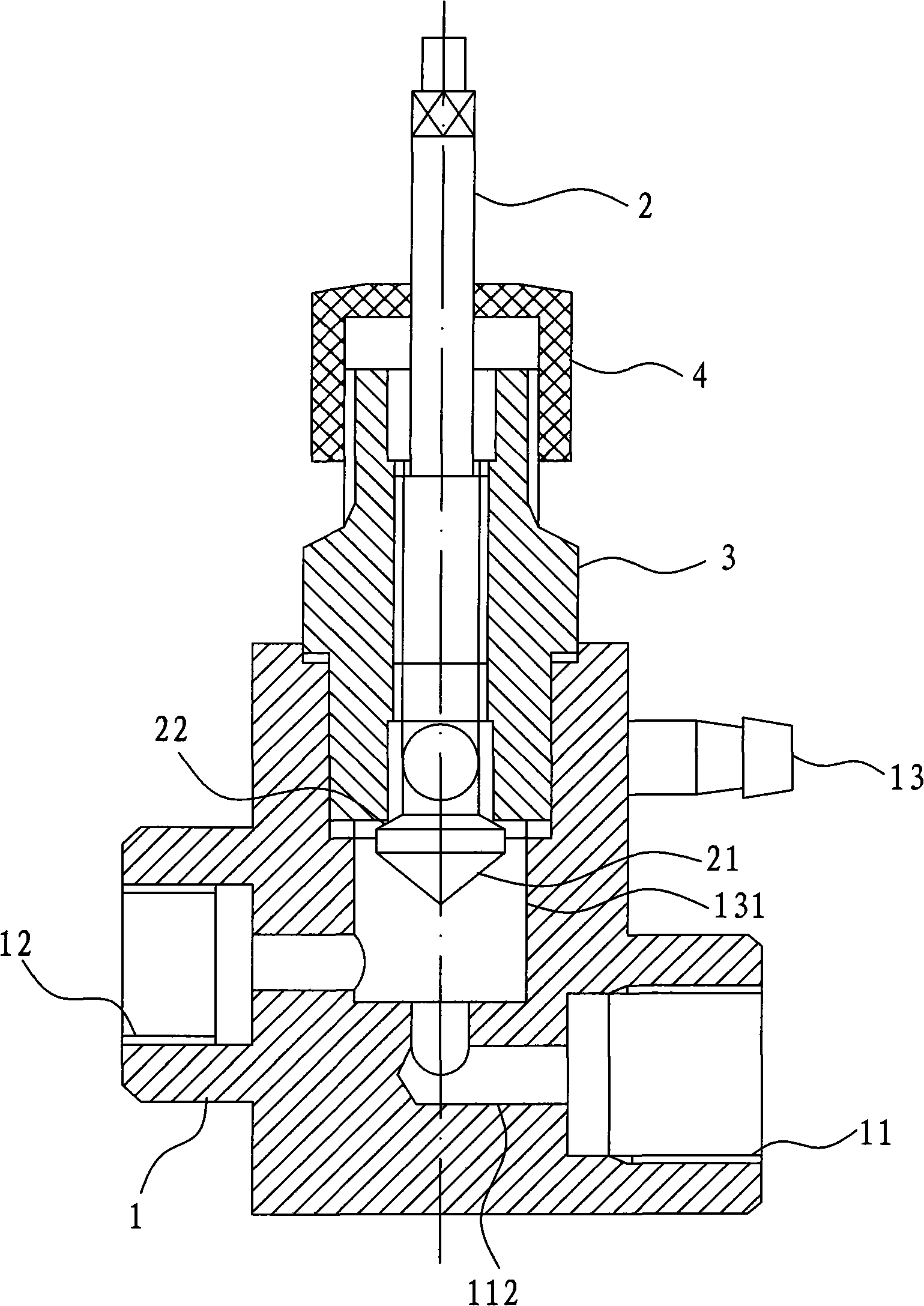

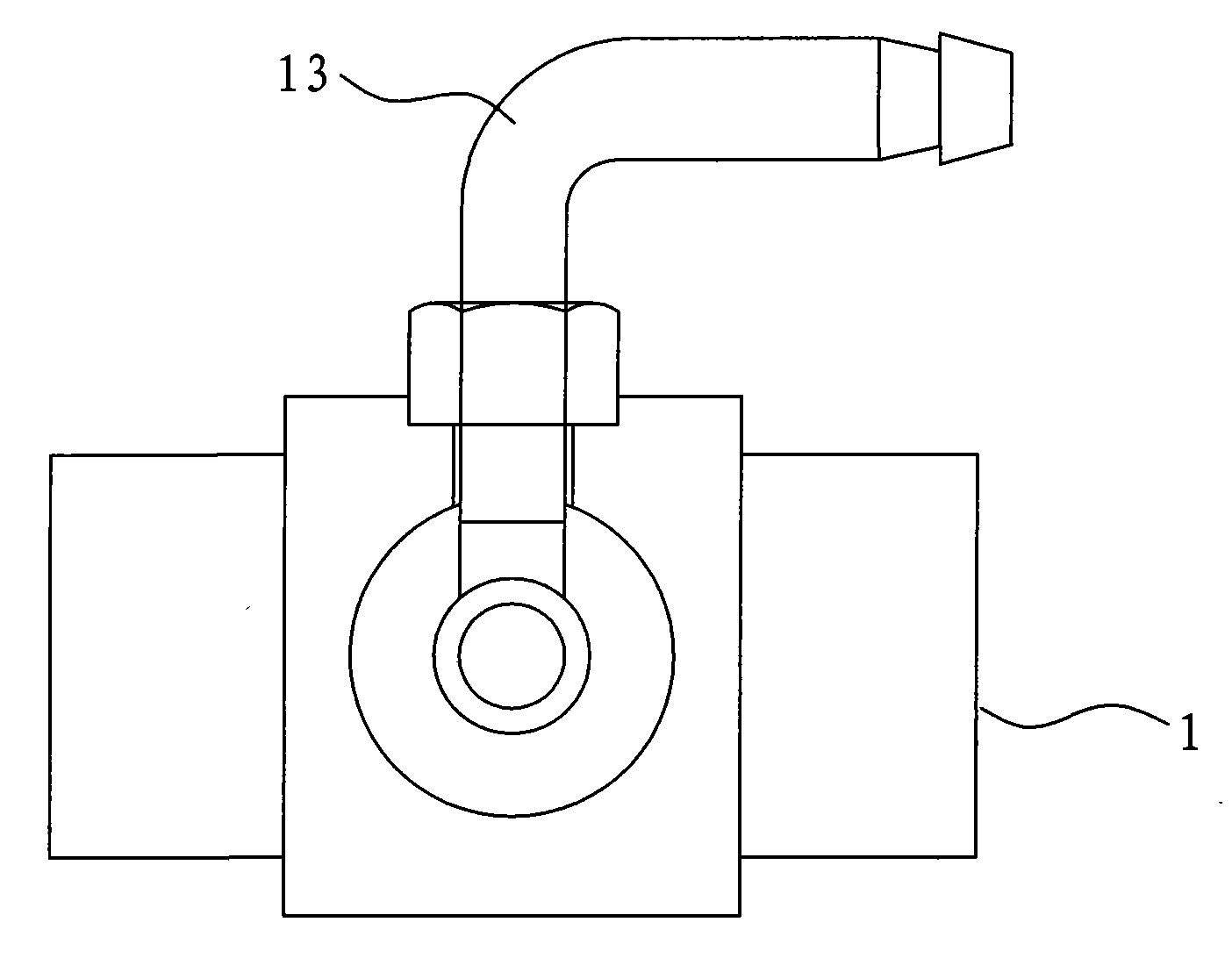

[0008] refer to figure 1 with figure 2 , the embodiment of the present invention discloses a kind of petroleum sampling valve that is used on the pipeline of oil field, and it comprises valve body 1, pressure gauge (not shown in the figure), valve stem 2, cock 3 and nut 4, and described valve The body 1 is provided with a liquid inlet 11, a liquid outlet 12 and a sampling port 13, and the liquid inlet 11 and the liquid outlet 12 are communicated through a liquid channel 112 arranged in the valve body 1, and the sampling port 13 It communicates with the middle part of the liquid channel 112 through the sampling channel 131 provided in the valve body 1, the cock 3 is screwed on the valve body 1, the valve stem 2 is screwed on the cock 3 through an external thread and one end is located outside the valve body 1, the valve There is a limit step on the stem 2, and the nut 4 is set on the cock 3 to prevent the valve stem 2 from falling off the valve body 1 through the limit step. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com