Split electronic pattern sewing machine

A pattern machine and split-type technology, applied in the field of sewing machines, can solve the problems of increased labor costs, difficulty in sewing, insufficient head stroke, etc., and achieve the effects of saving costs, improving benefits, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

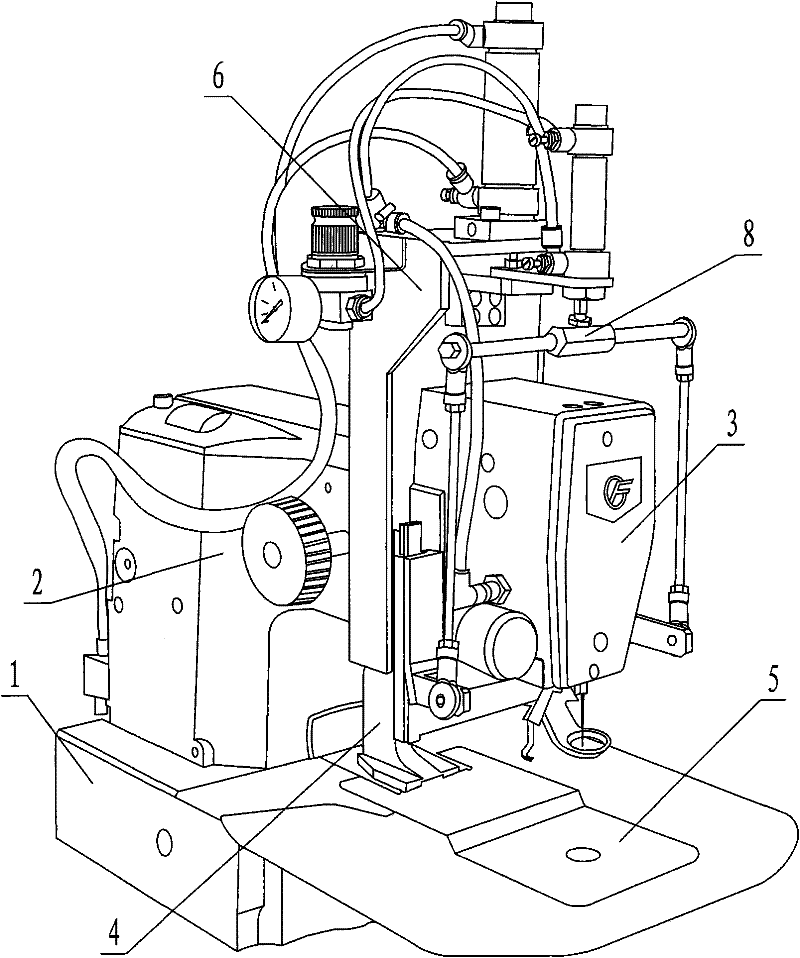

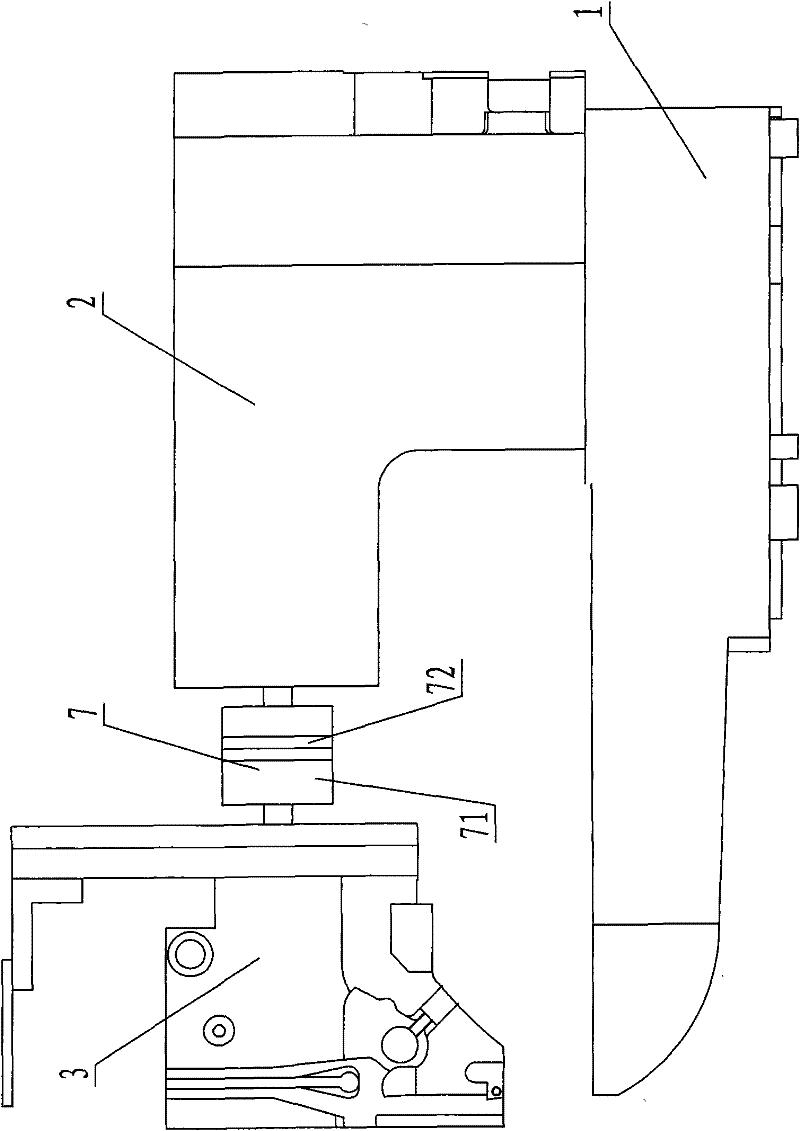

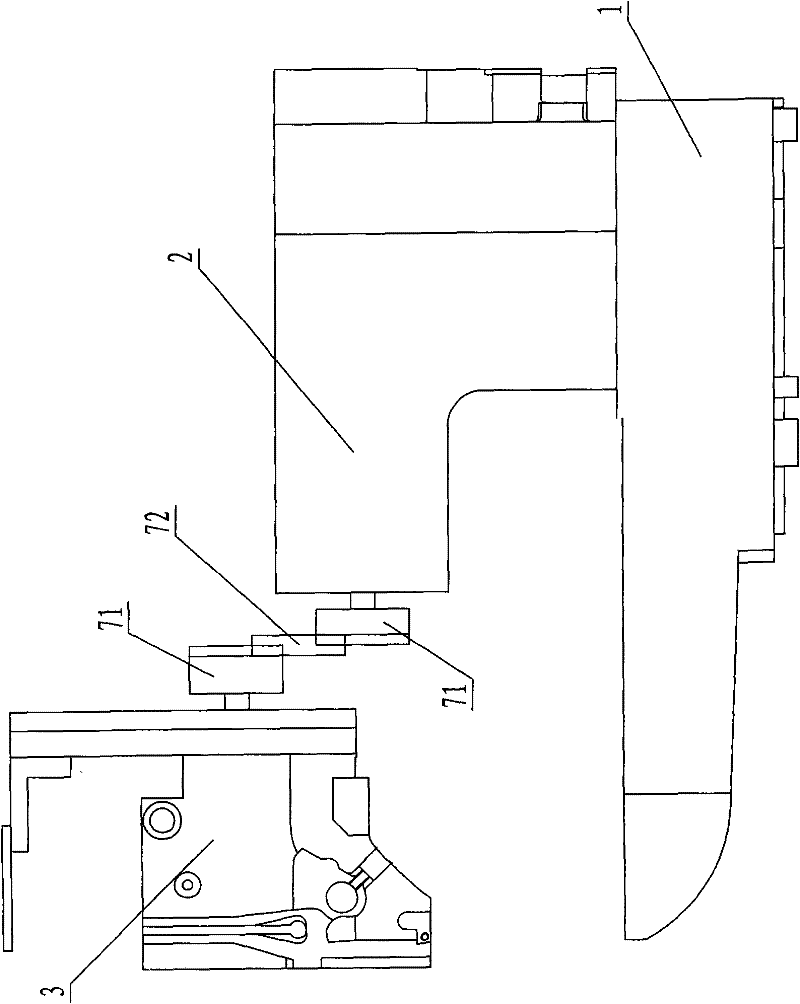

[0020] like figure 1 The split-type electronic pattern machine shown is improved from the original integrated electronic pattern machine. Including base 1, fuselage 2 fixed on base 1, machine head 3, upper feeding bow 4 and lower feeding carriage 5 fixed with upper feeding bow 4, fuselage 2 is separated from machine head 3, A set of lifting device 6 is arranged between the body 2 and the nose 3, the nose 3 is fixed on the lifting device 6 and moves up and down relative to the fuselage 2 through the lifting device 6, thereby raising the nose 3 so that the nose 3. There is enough floor space. In order to realize the transmission connection between the body 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com