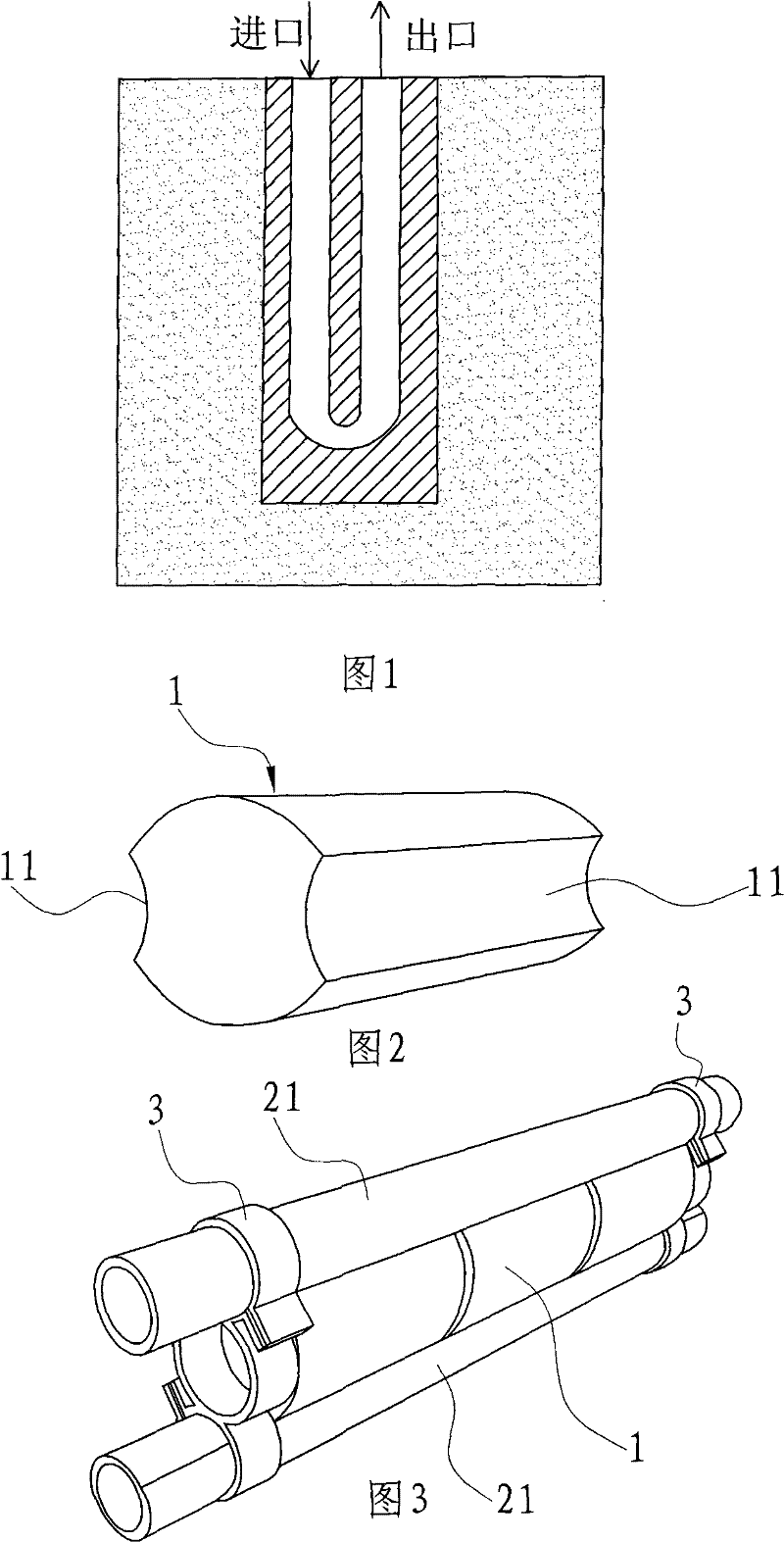

Heat insulation device for U-shaped pipe laying heat exchanger

A heat insulation device and heat exchanger technology, which is applied in the direction of heat insulation protection pipelines, heat pumps, pipeline protection, etc., can solve the problems of increased thermal short circuit loss, affecting refilling grouting materials, and increasing the number of U-shaped pipes, etc., to achieve The effect of heat exchange improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

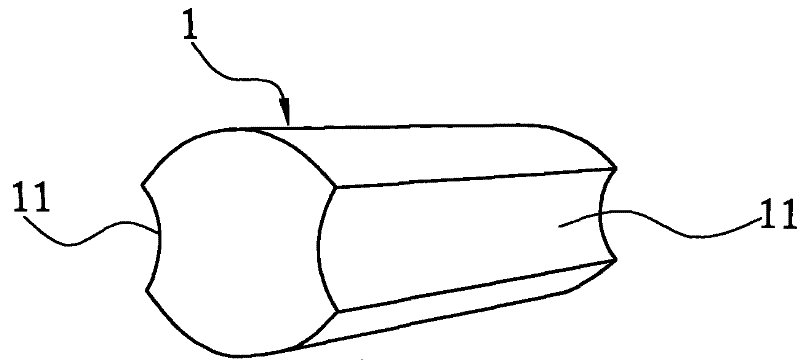

[0025] see figure 2 , 3 The heat insulation device of the U-shaped borehole heat exchanger provided by the present invention includes a body 1, and the outer wall of the body 1 is axially symmetrically provided with a straight pipe section 21 of the single U-shaped heat exchange tube of the heat exchanger. The arc-shaped groove 11, and the body 1 is made of a material with a thermal conductivity within 0.02W / (m·K)~0.06W / (m·K) and a water absorption within 0.05~0.1%.

[0026] Here, the body 1 is generally cylindrical, and the diameter of the body 1 is slightly larger than the diameter of the straight pipe section 21 of the single U-shaped heat exchange tube of the heater.

[0027] During assembly, the heat insulating device and the single U-shaped heat exchange tube of the heat exchanger can be fastened with the fixing frame 3 .

Embodiment 2

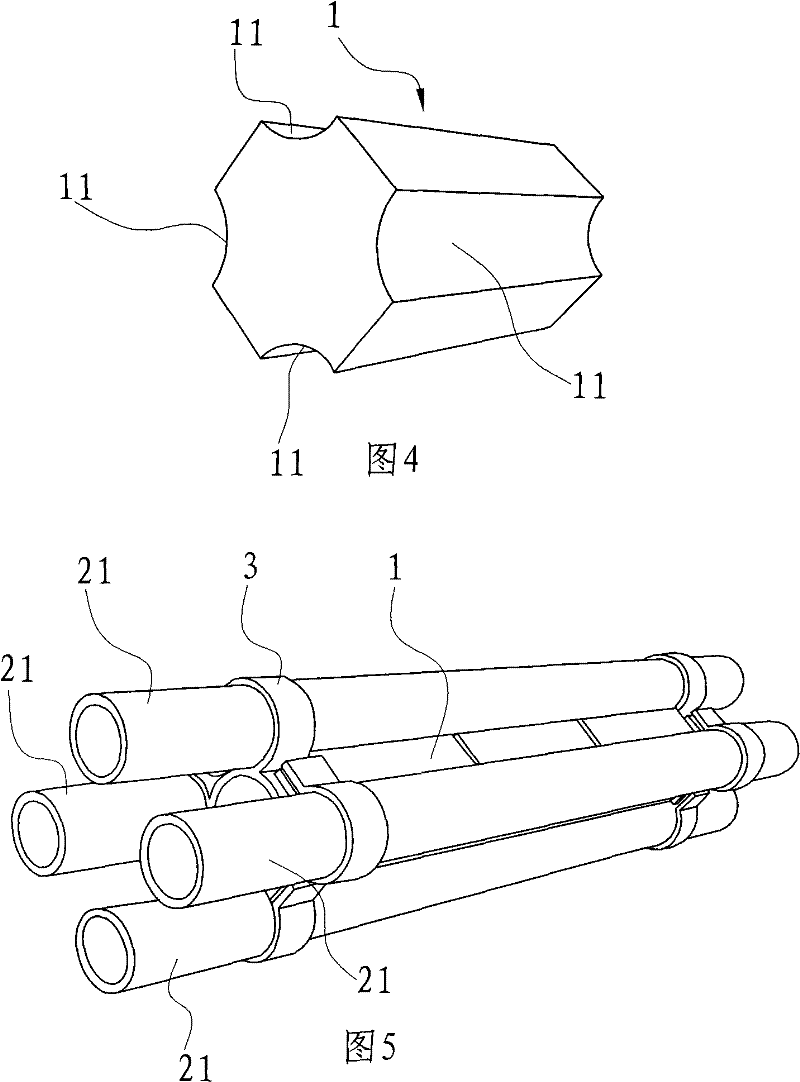

[0029] Different from the first embodiment, there are four arc-shaped grooves on the outer wall of the main body, which are arranged in a symmetrical structure. The heat insulation device of this structure is suitable for double U-shaped heat exchange tubes.

[0030] The main body 1 is generally column-shaped, and four arc-shaped grooves 11 are respectively arranged on the four corners of the column, and are fitted with the straight pipe sections 21 of the double U-shaped heat exchange tubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com