Dual injection molding method of a built-in insertion piece and a built-in insertion piece type electric-device housing that produced by the method

A technology of injection molding and electronic devices, applied in the direction of electrical equipment shells/cabinets/drawers, chemical instruments and methods, instruments, etc., can solve the problems of easy falling, weak adhesion, weak label adhesion, etc., to achieve strong strength, The effect of preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The double-material injection molding method of the present invention and the injection molded products manufactured by this method can be applied to the external casings of all electronic devices, but for the convenience of illustration and description, the external casings for desktop computers and the external casings for notebook computers are used. The present invention will be described centering on the casing.

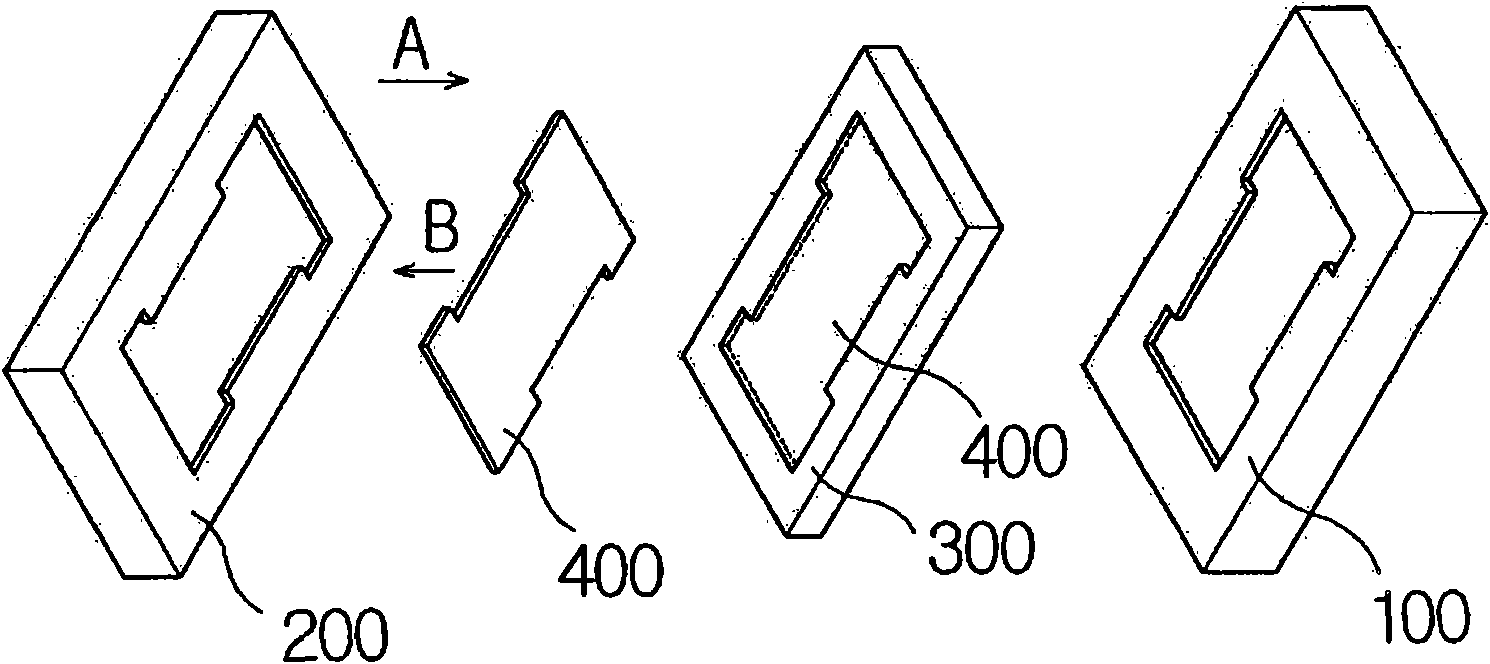

[0023] First, refer to figure 1 The two-material injection molding method related to the present invention will be described in detail. The first embodiment of the present invention is a double injection molding method by using a double injection molding apparatus including a first mold assembly 100, 200 having a fixed mold 100 and a movable mold 200 and a second mold assembly (not shown). shown), an injection liquid injection port (not shown) is respectively formed on the above-mentioned fixed mold, and an inlet (not shown) for injection liquid injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com