Nitrogen generating vehicle

A nitrogen, vehicle owner technology, applied in motor vehicles, vehicle parts, goods transport vehicles, etc., can solve the problems of inconvenient operation, difficult movement, long pipelines, etc., to improve operational flexibility, enhance maneuverability, and overall compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

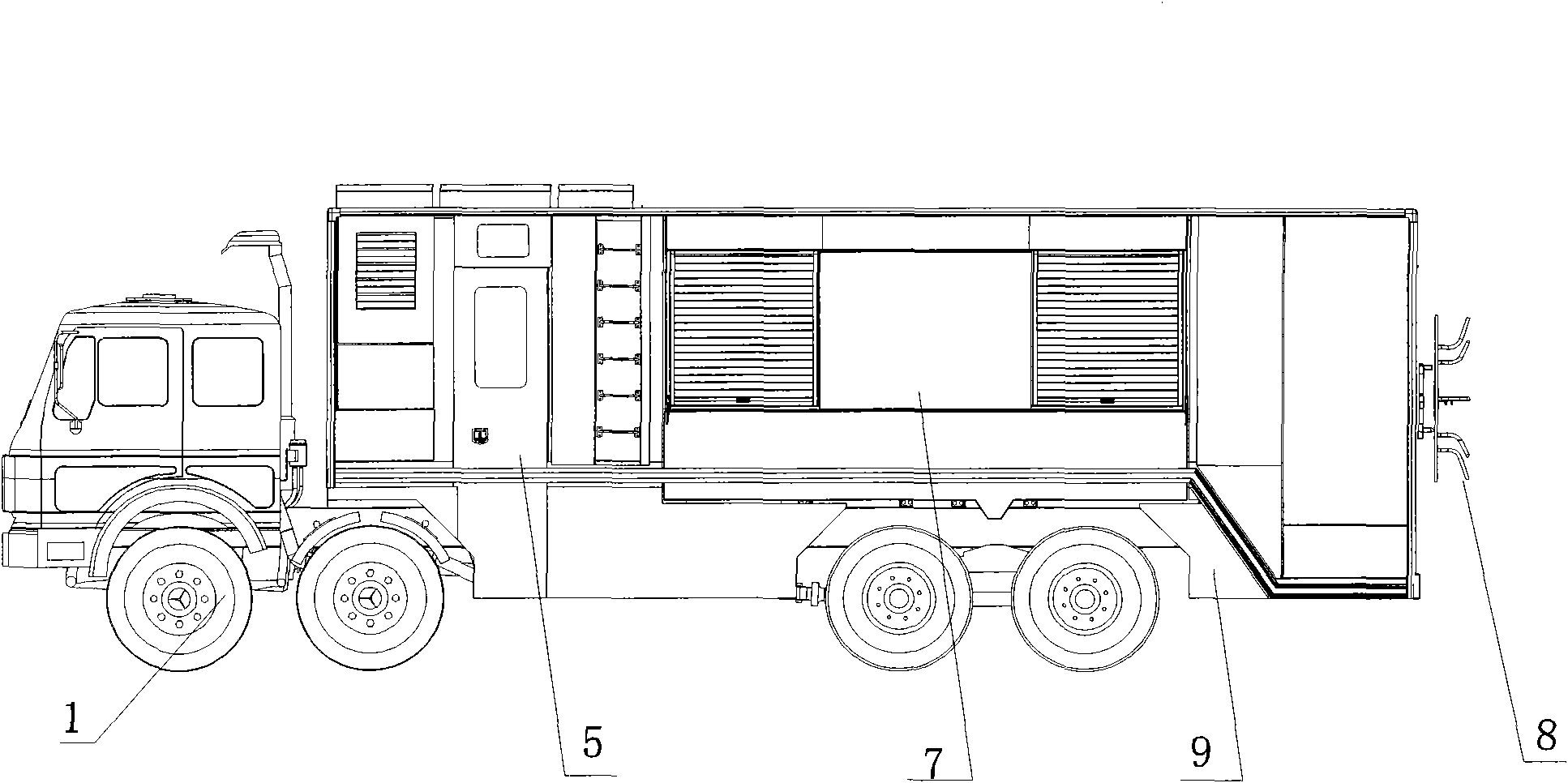

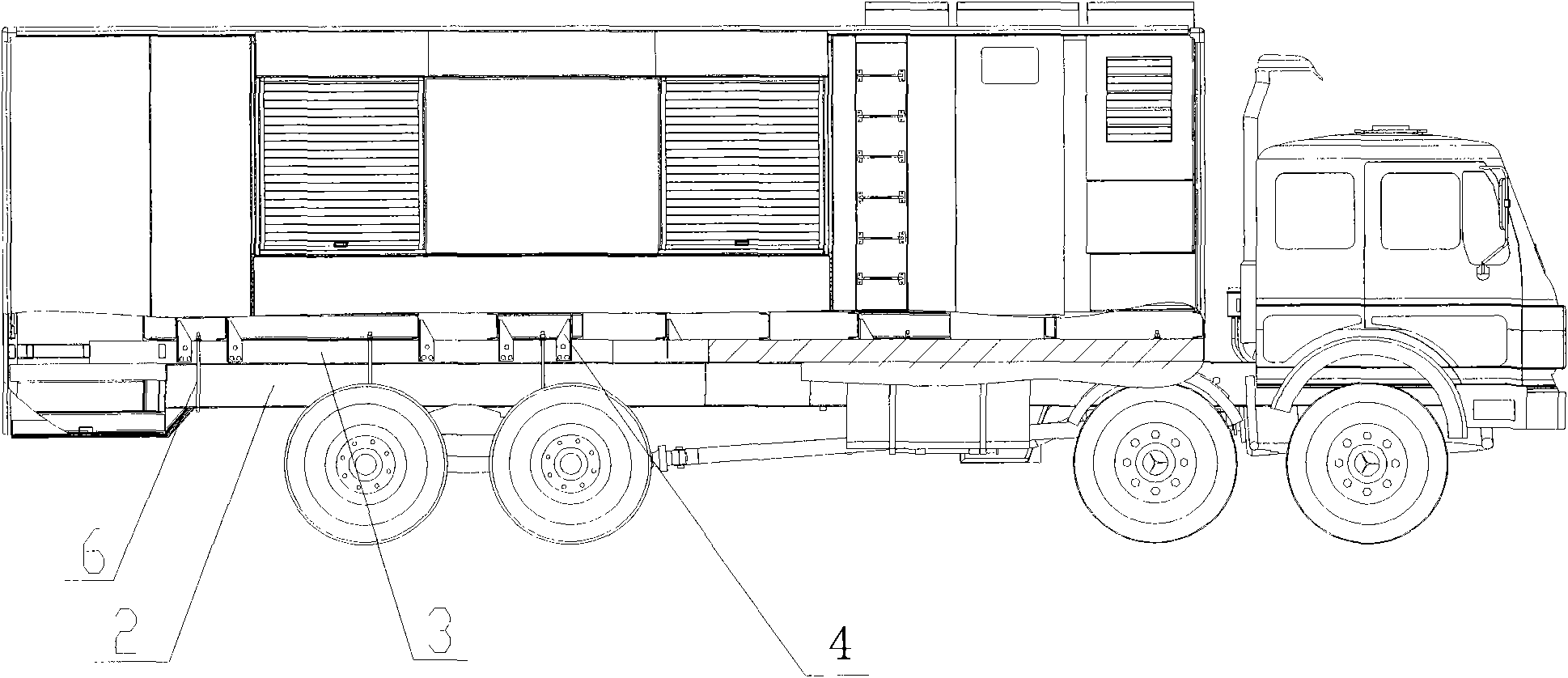

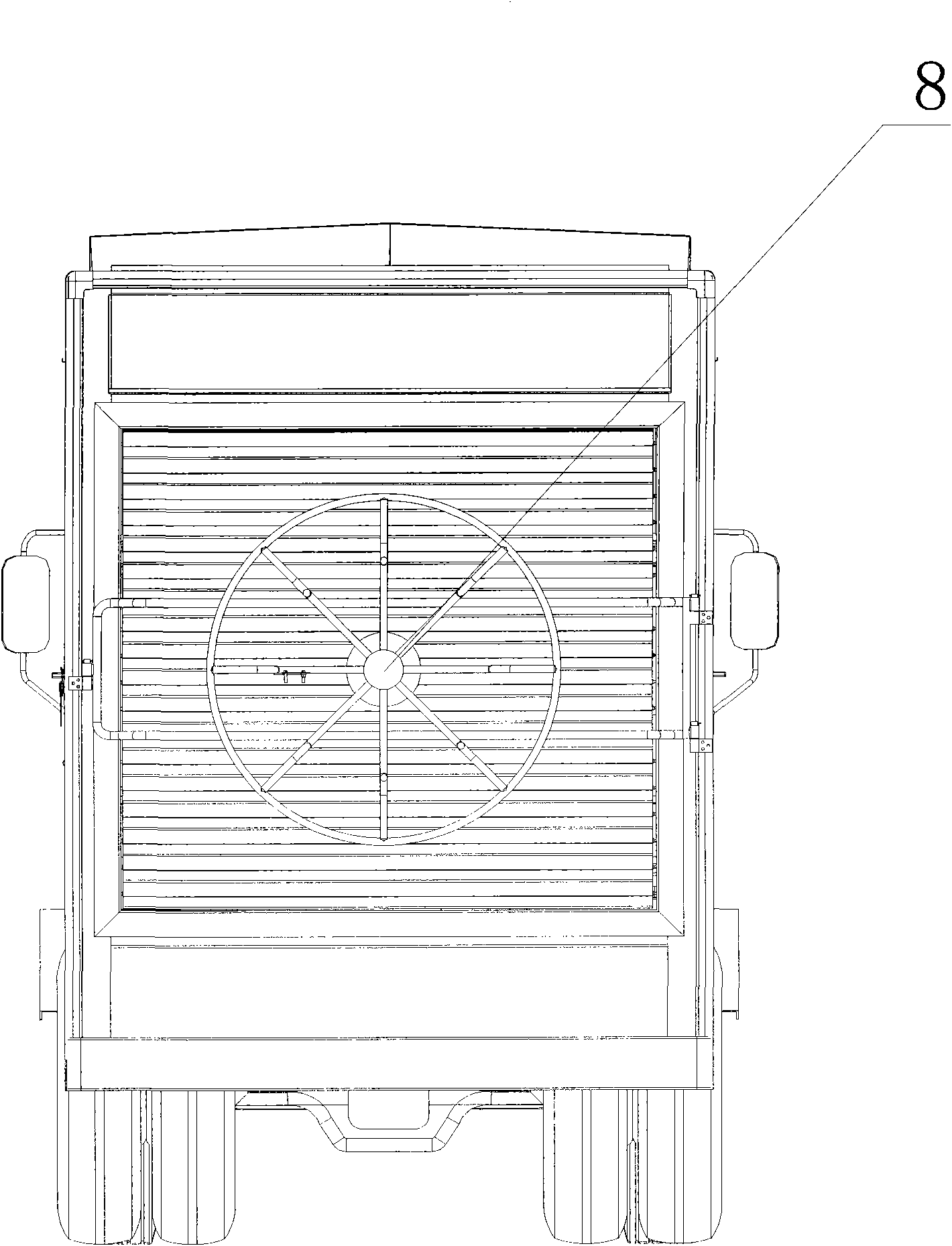

[0031] combine Figure 1-Figure 7 , the following detailed description is given to the nitrogen generation special operating vehicle of the present invention.

[0032] The nitrogen generating vehicle provided by the present invention adopts a standard on-board skid, and the whole skid is connected with the second-class automobile chassis 1 to form a special operation vehicle.

[0033] The chassis main beam 2 is connected to the chassis sub-frame 3 through U-shaped bolts 6, and the chassis sub-frame 3 is connected to the equipment bottom skid 5 through an angled connecting plate 4. Both sides of the equipment skid 5 are provided with hydraulic flying wing doors 7, and a movable hose winding frame 8 is also provided on the work vehicle.

[0034] The sub-frame 3 of the chassis is welded with C-shaped channel steel, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com