Stacking energy-saving water tank of automatic circulation pipe network

An automatic circulation and pipe network technology, applied in water saving, electric fluid pressure control, water supply devices, etc., can solve the problems of water pollution, water cannot be replaced automatically, low efficiency of variable frequency booster main pump, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

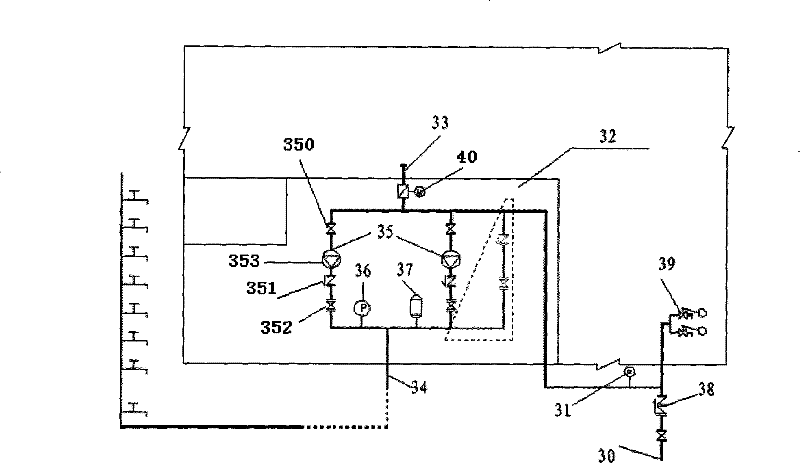

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

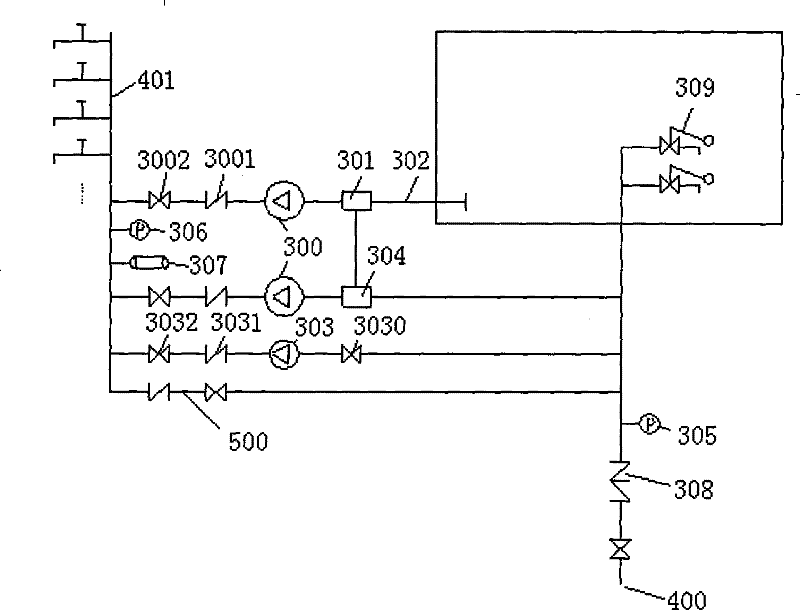

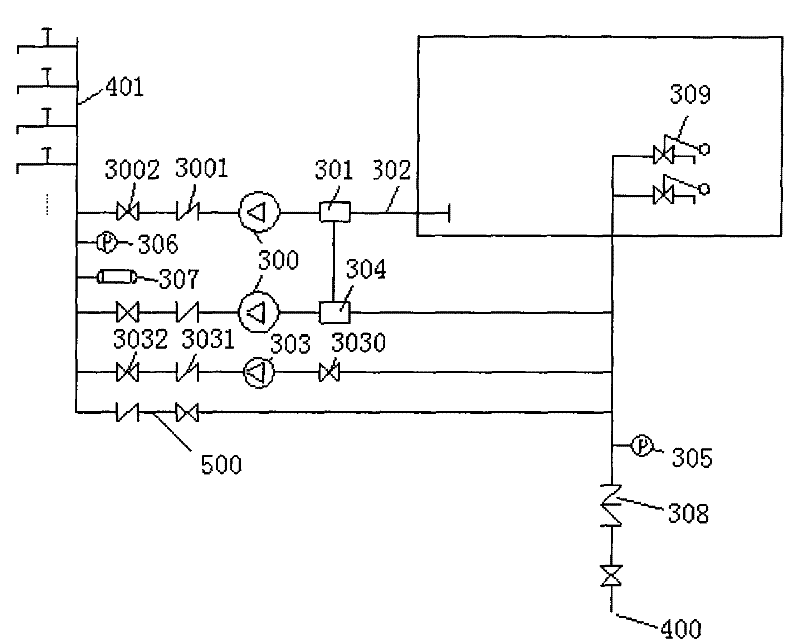

[0012] by figure 2 It can be seen that the present invention includes: an electrolysis point pressure gauge 305 with one end connected to municipal tap water 400, and the other end of the electric contact pressure gauge 305 is connected to one end of the pipe network stacking water inlet mechanism and the bypass pipeline 500; The net stacking water inlet mechanism includes: two sets of three-way electric valves (301, 304) connected in series; the other end of one set of three-way electric valves 301 is connected to the outlet 302 of the water tank, and the other end of the other set of three-way electric valves 304 is connected to the electric The other end of the contact pressure gauge 305 is connected; the third end of a group of three-way electric valve 301 and the third end of another group of three-way electric valve 304 are respectively passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com