Ultraprecise electrohydraulic servo-controlled dynamic-static pressure bearing and feed mechanism

A dynamic and static pressure bearing and servo control technology, applied in the field of dynamic and static pressure bearings, can solve the problems of small friction and higher and higher requirements for spindle rotation accuracy, and achieve the effects of good vibration resistance, high rotation accuracy and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are exemplified, and the ultra-precision electro-hydraulic servo-controlled dynamic and hydrostatic bearing and the feed mechanism of the present invention are described in detail as follows:

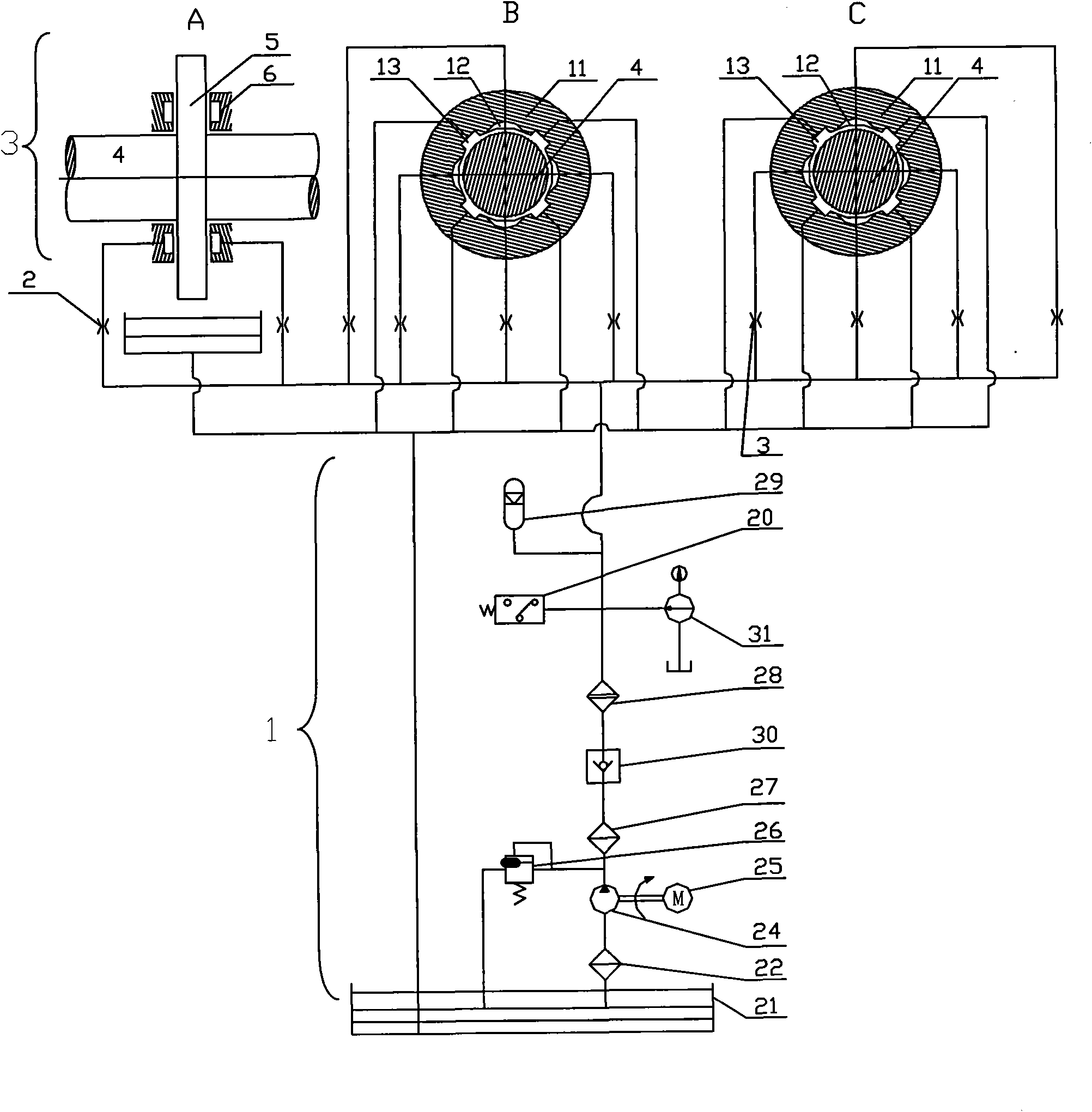

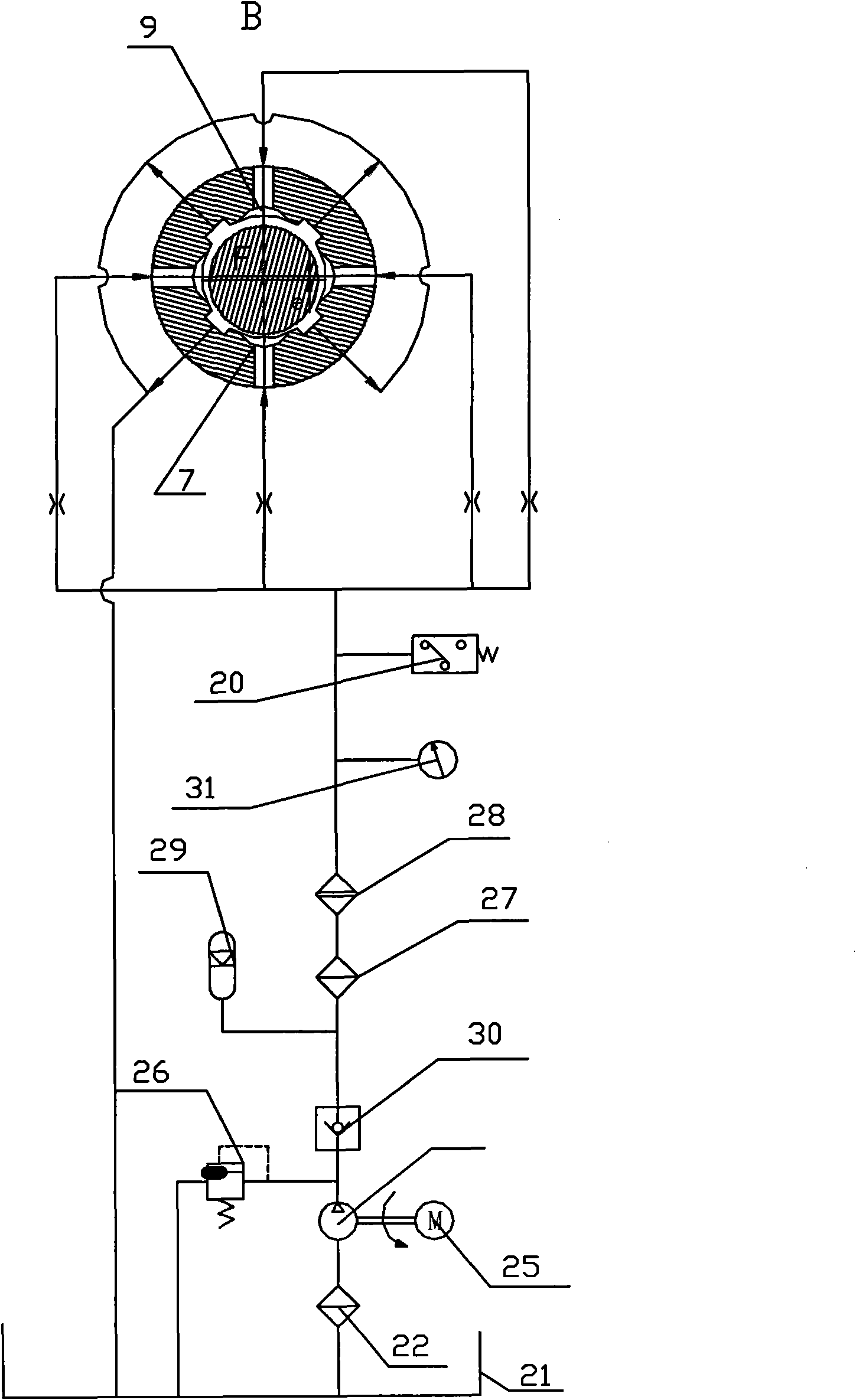

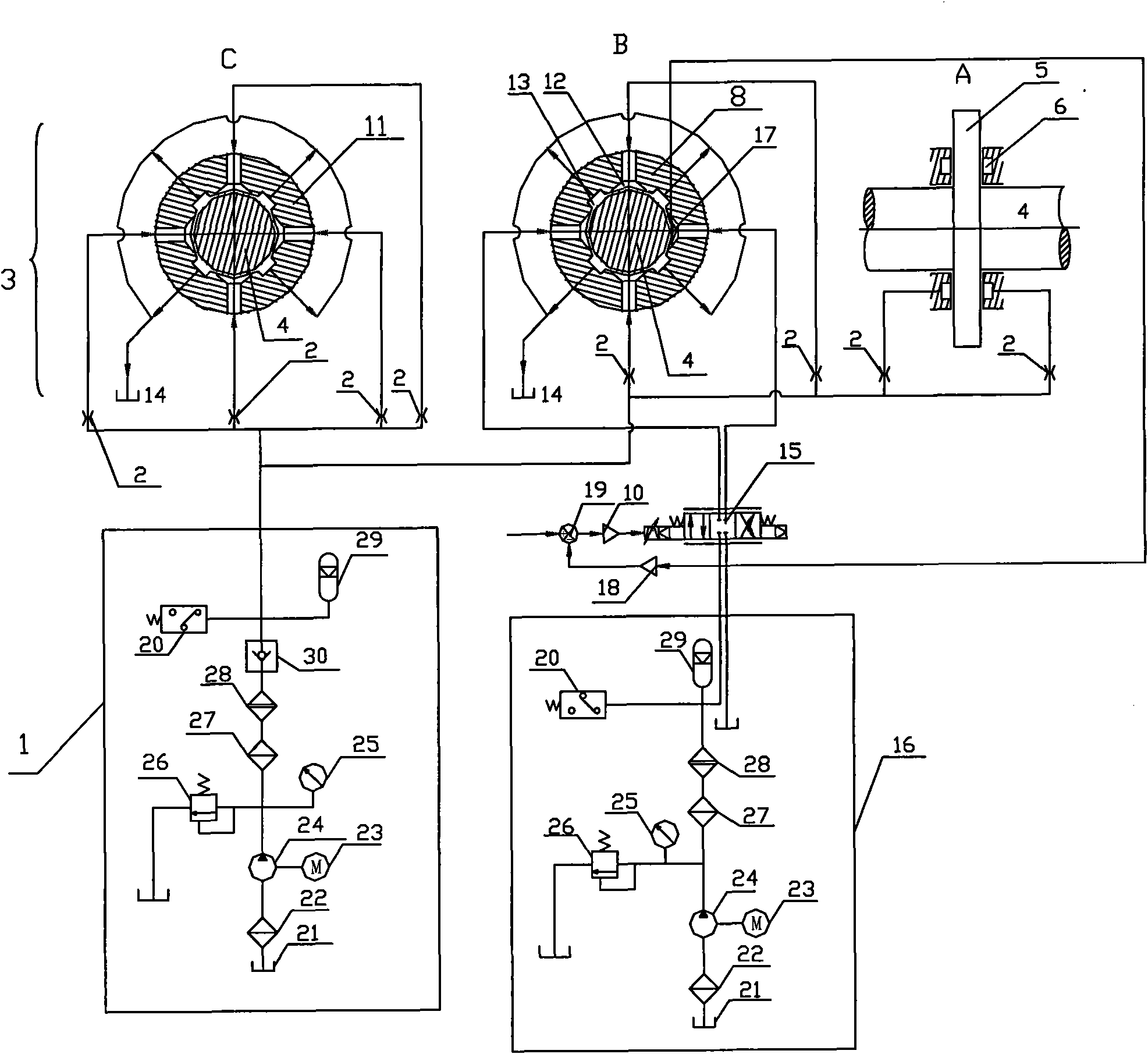

[0024] Such as image 3 As shown, the ultra-precision electro-hydraulic servo-controlled dynamic and static pressure bearing and feed mechanism of the present invention include a first oil supply system 1 that supplies oil to the main shaft mechanism 3 through 8 small hole restrictors 2 respectively; The second oil supply system 16 in which the servo valve 15 supplies oil to the front centering hydrostatic bearing B in the main shaft structure 3; The dynamic and static pressure bearing sleeve 11 sleeved on the rear end of the main shaft 4 is composed of the static pressure thrust bearing sleeve 6 and the flange 5 arranged at an appropriate position at...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap