Automatic desludging and refreshing apparatus of sensitive layer of metal sensor

A metal sensor and automatic descaling technology, applied in the detection field, can solve the problems of inability to realize production detection and troubles, and achieve the effect of simple structure, not easy to damage, and removal of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

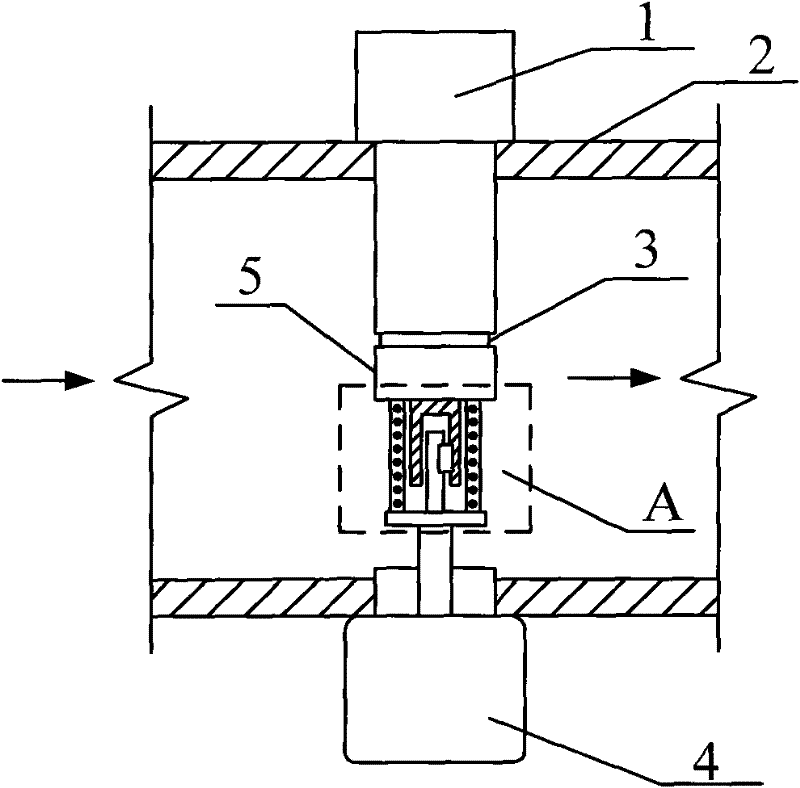

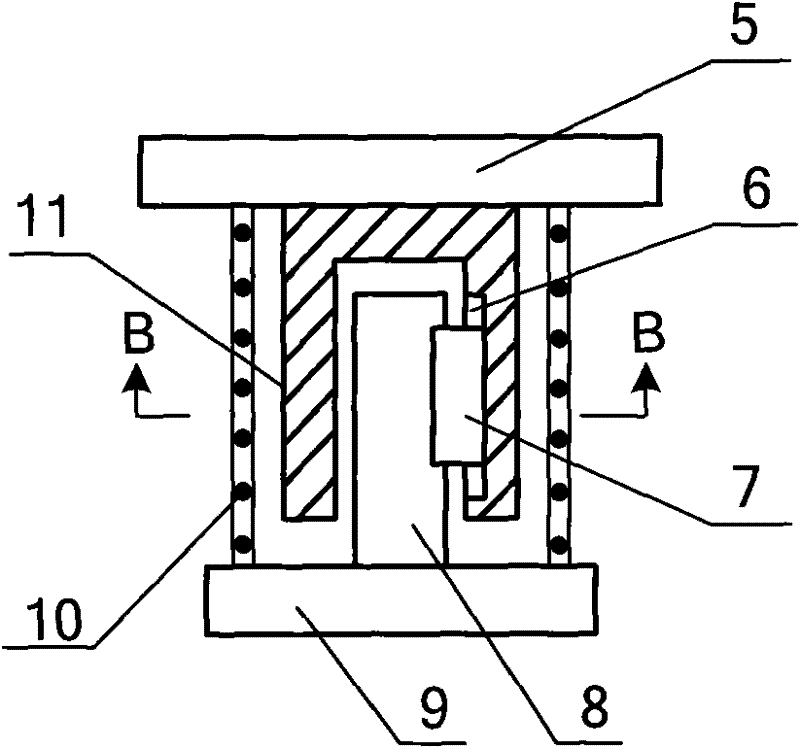

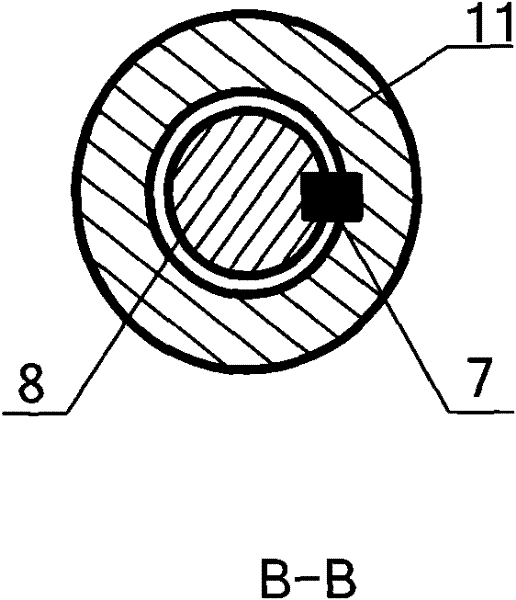

[0011] Such as figure 1 , 2 As shown in and 3, the automatic descaling and refreshing device for the sensitive layer of the metal sensor includes a motor 4, a support plate 9, a transmission shaft 8, a shaft sleeve 11, a limit pin 7, a spring 10, and a scraper 5; the power output shaft of the motor 4 passes through vertically The side wall of the penetrating detection pipeline 2 is set, the support plate 9, the transmission shaft 8, the shaft sleeve 11, the limit pin 7, the spring 10, and the scraper 5 are all arranged in the detection pipeline 2; the support plate 9 is disc-shaped, and the motor 4 The end of the power output shaft is fixedly connected with the center of the bottom surface of the support plate 9, one end of the transmission shaft 8 is fixedly connected with the center of the top surface of the support plate 9, and the side wall of the transmission shaft 8 is fixed with the limit pin 7; A cylindrical shape with a closed surface and an open bottom surface. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com