Liquid crystal panel repairing machine with fast lighting function

A liquid crystal panel, fast technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of time-consuming and time-consuming, and achieve the effect of improving manufacturing efficiency and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the structure and characteristics of the present invention in detail, the following two preferred embodiments are given and described in conjunction with the accompanying drawings as follows, wherein:

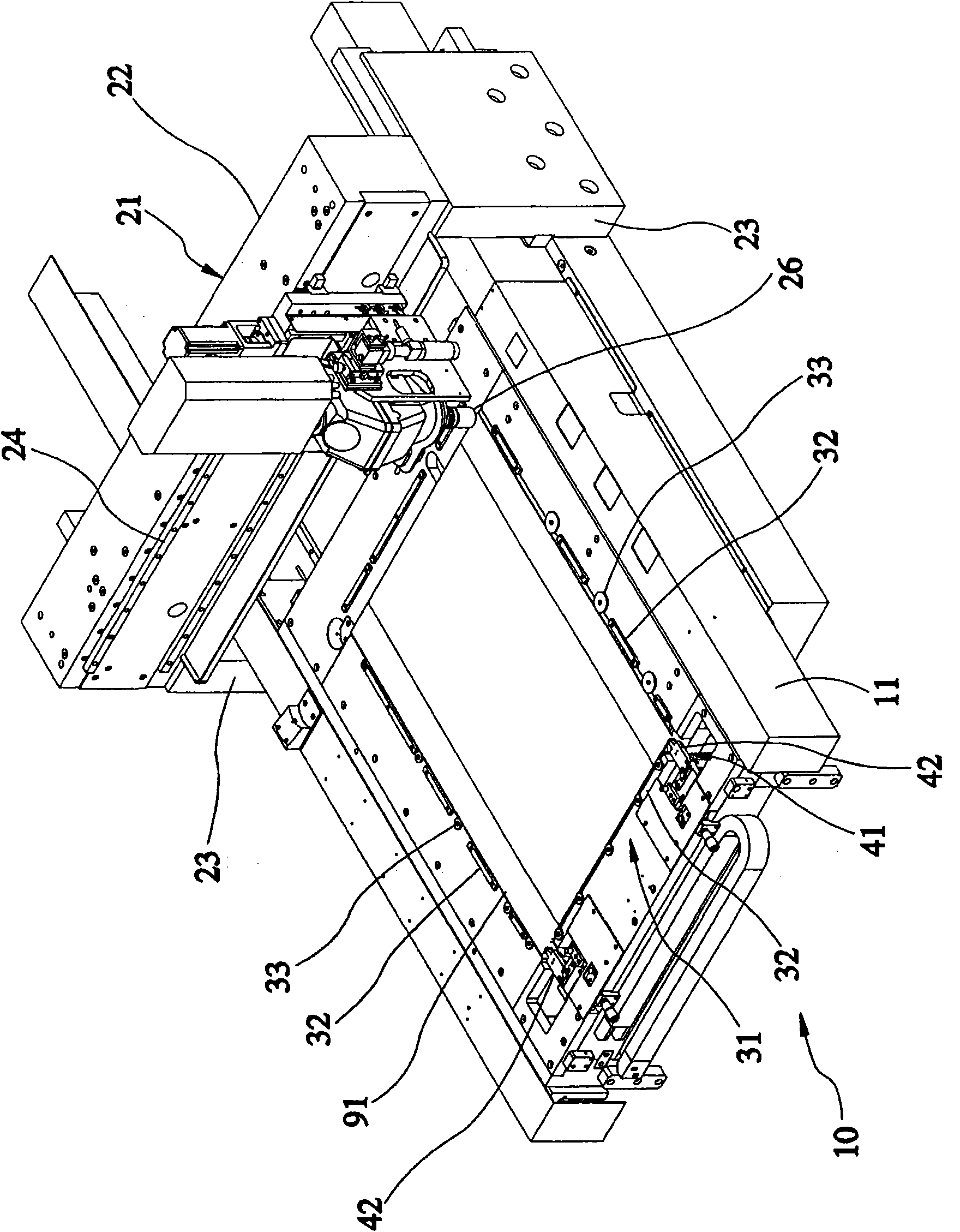

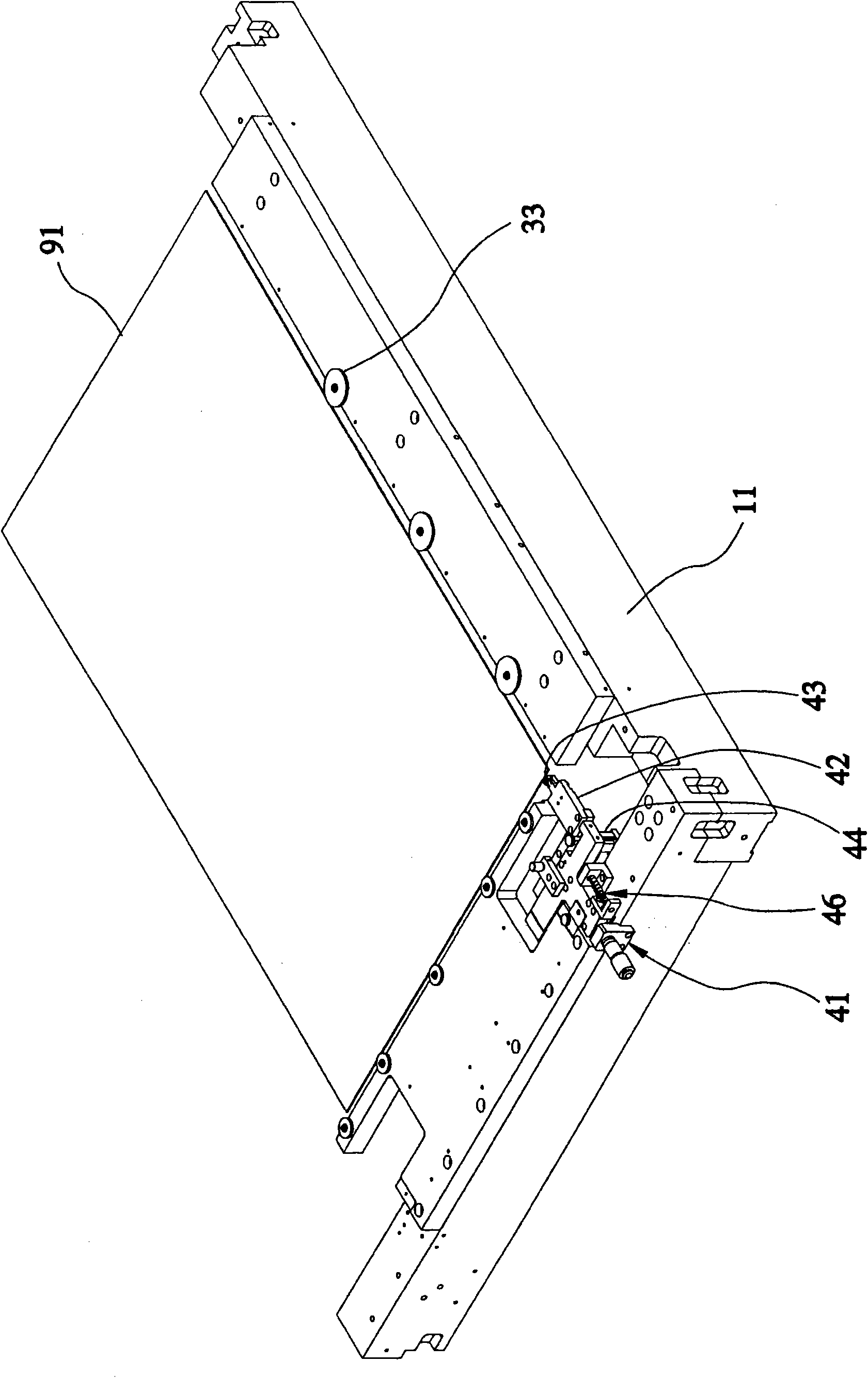

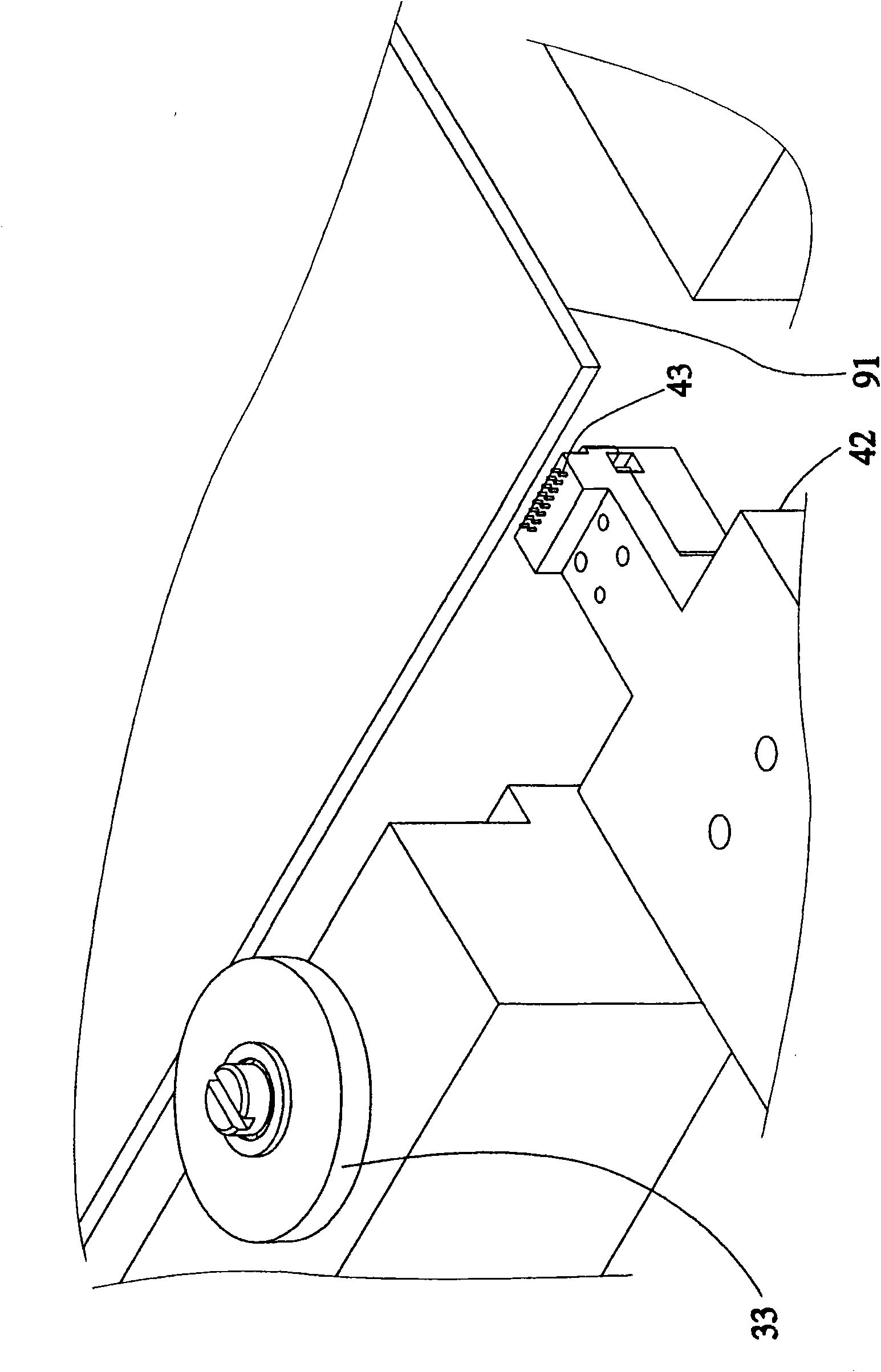

[0043] Such as Figure 1 to Figure 5 As shown, a liquid crystal panel repair machine 10 with fast lighting function provided by the first preferred embodiment of the present invention mainly consists of a carrying platform 11, a photographic laser mechanism 21, a clamping mechanism 31, and two quick contact mechanisms Composed of 41, of which:

[0044] The carrying platform 11 is used to receive a liquid crystal panel 91;

[0045] The imaging laser mechanism 21 is arranged on the carrying platform 11 and is located above the carrying platform 11 . The photographic laser mechanism 21 has a crossbeam 22, and the end of the crossbeam 22 has a foot 23 straddling the two sides of the carrying platform 11 in a front and rear sliding manner; the crossbeam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com