Crossed belt type permanent magnetic separator

A magnetic separator and cross-belt technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as poor use effect, and achieve the effect of simple structure, good separation effect, and convenient manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

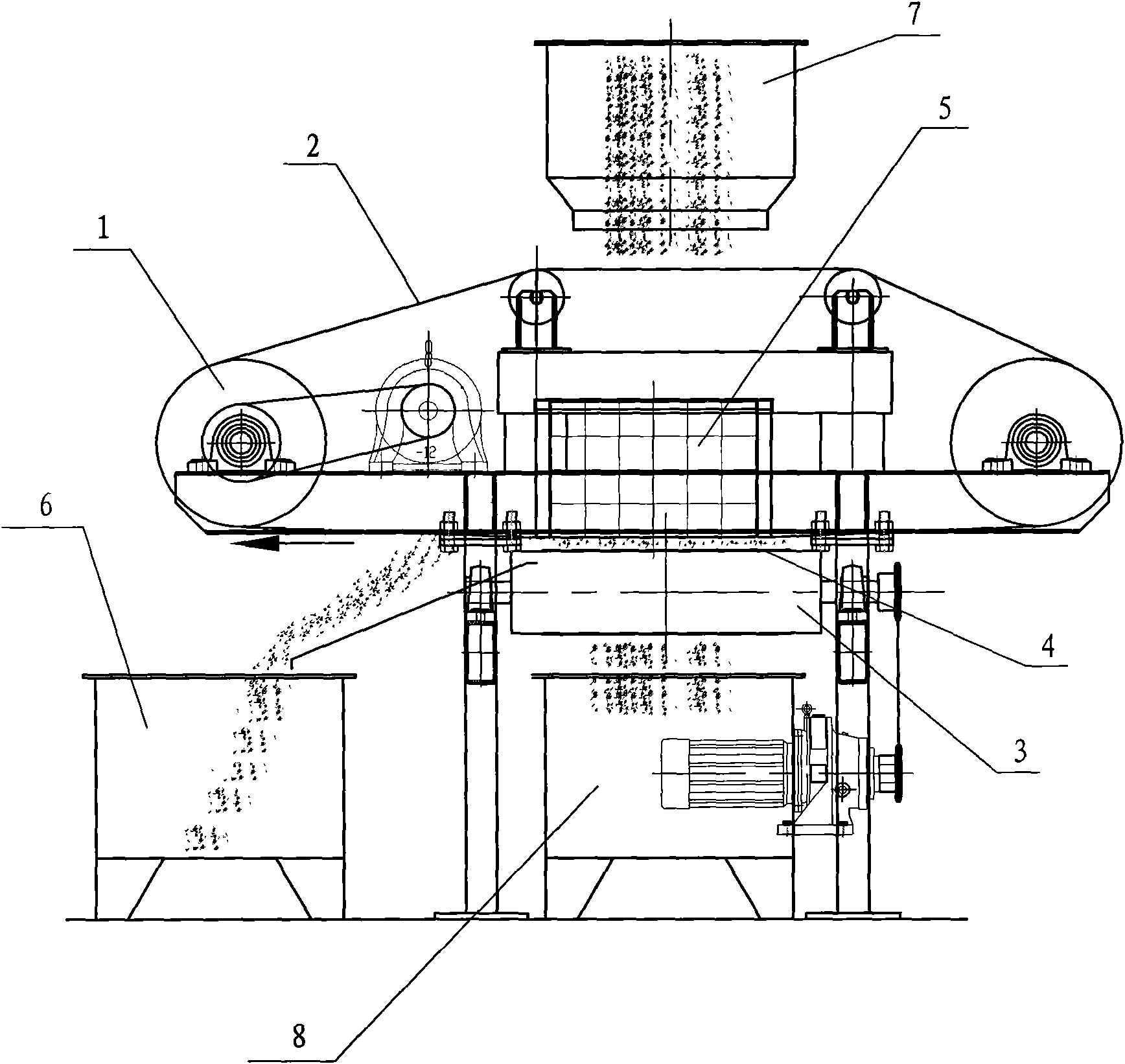

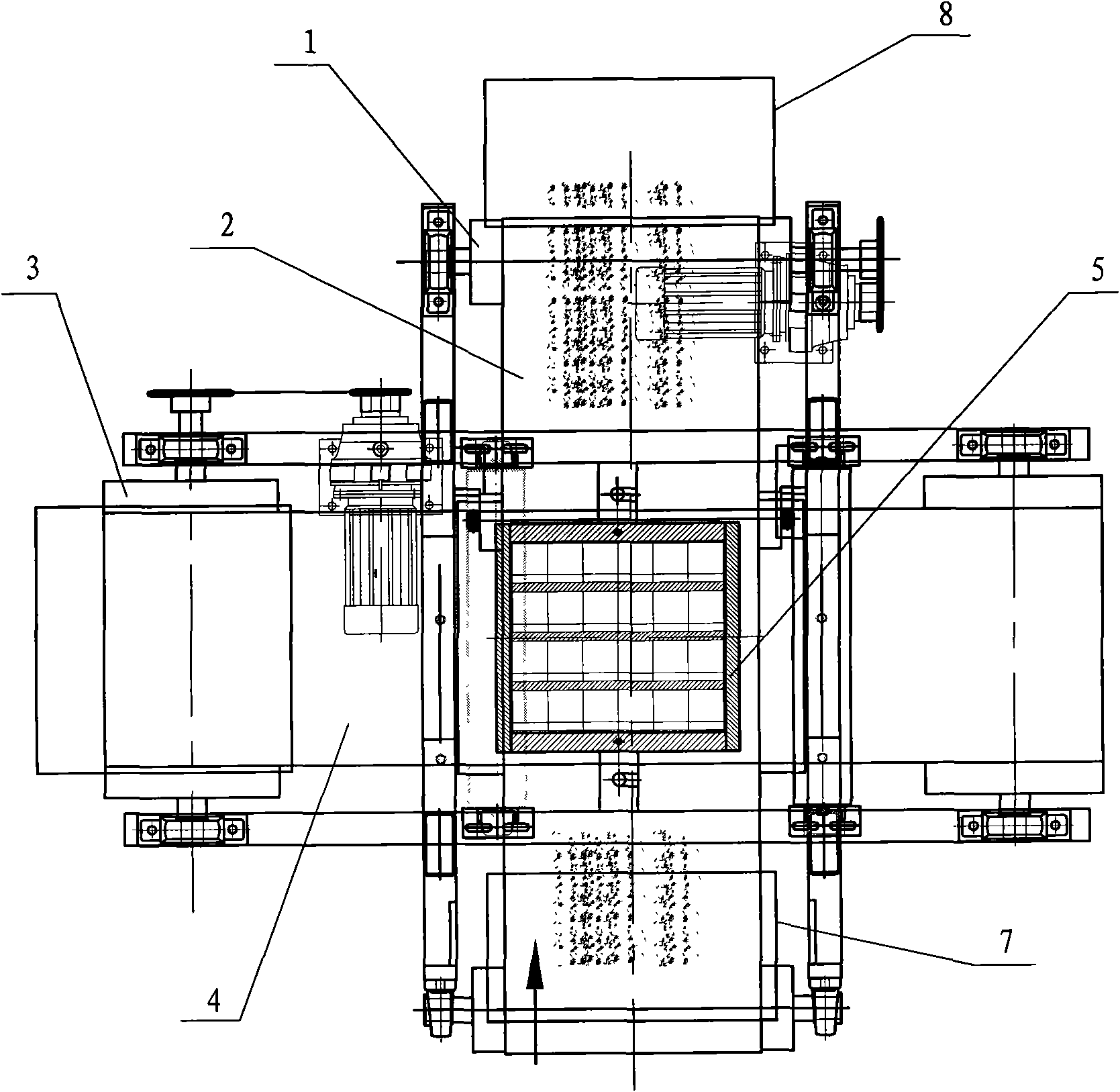

[0009] Included in the accompanying drawings: feed drum 1, feed endless belt 2, material selection drum 3, material selection endless belt 4, permanent magnet 5, magnetic hopper 6, feed hopper 7, non-magnetic hopper 8.

[0010] As shown in the figure, during the working process of the present invention, the material containing ferromagnetic parts is fed from the feed hopper 7 at the front end of the feeding endless belt 2, and the material is evenly sprinkled on the feeding endless belt 2, and the feeding endless belt carries the iron-containing material. The material of the magnetic parts enters the bottom of the material selection endless belt 4 at a high speed, and under the action of the permanent magnet 5, the ferromagnetic material in the material is automatically sucked to the lower surface of the moving material selection endless belt 4; The material moves with the material selection endless belt 4, and when the ferromagnetic material moves out of the suction range of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com