Device for separating printing plates

A technology of printing plates and driving devices, which is applied in the field of printing plate devices, can solve the problems of structural consumption and inability to adapt the mode of action, and achieve the effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

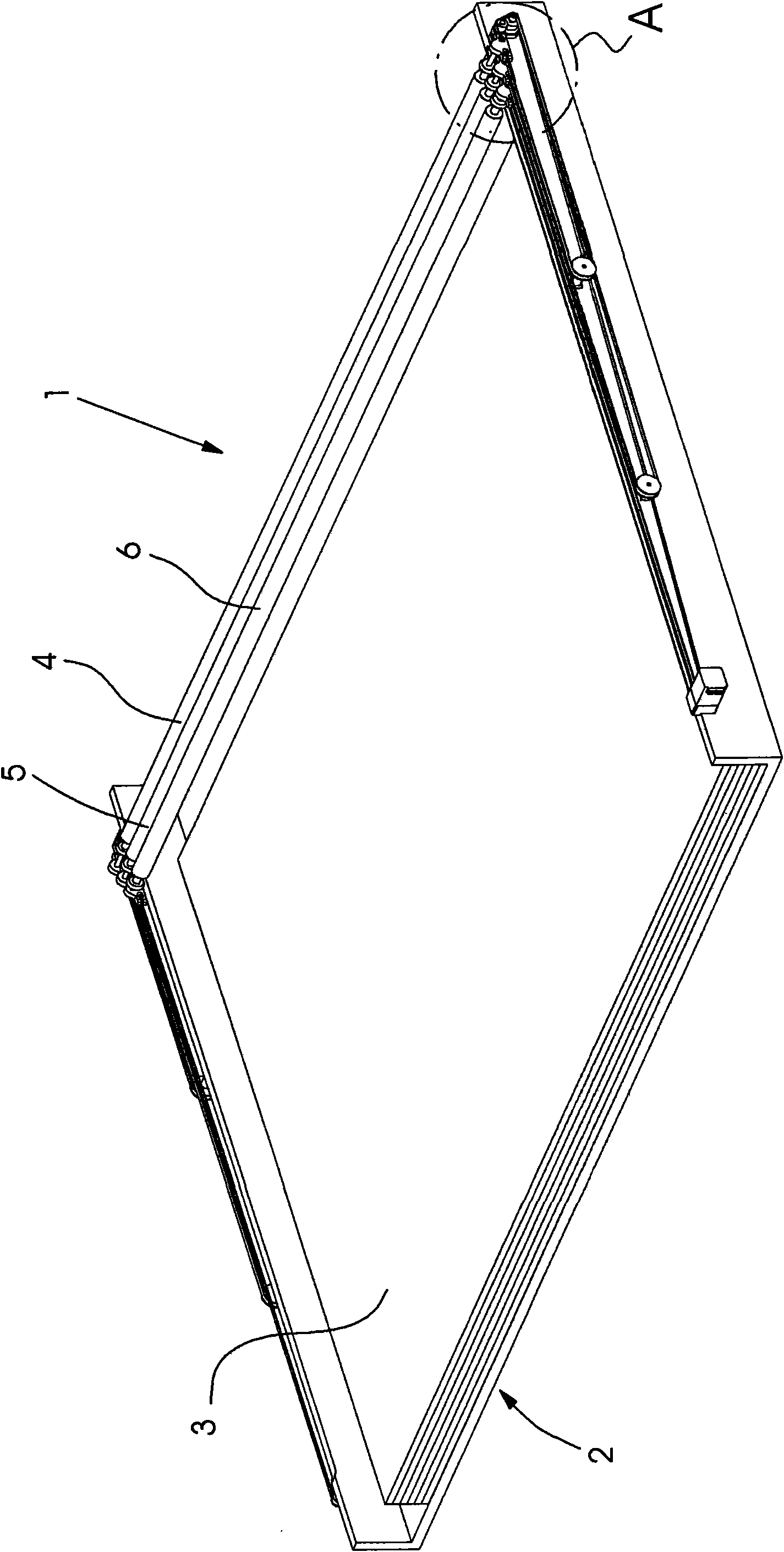

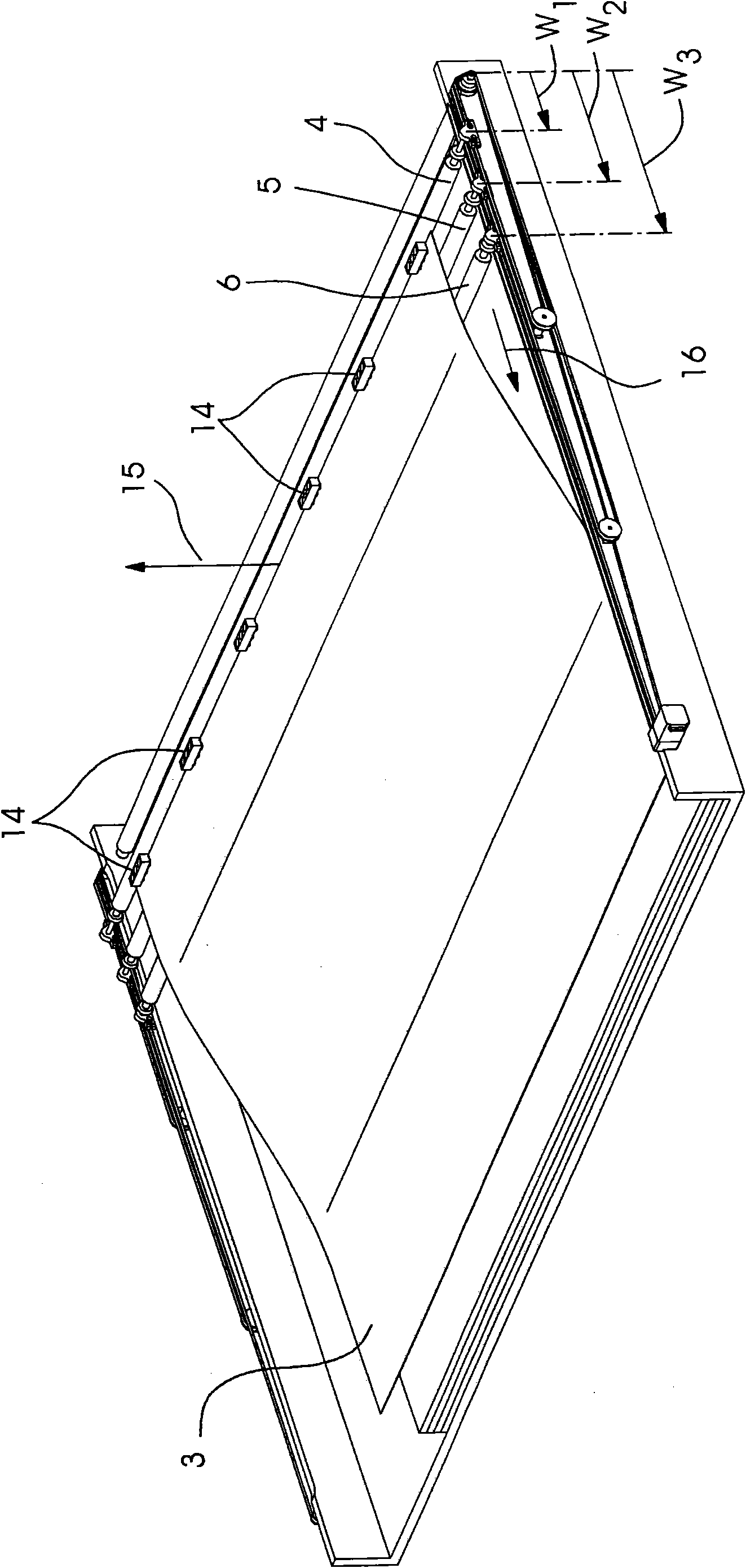

[0030] figure 1 A separating device 1 is shown, which is fed with printing plates 3 in the form of stacks via a printing plate pallet 2 .

[0031] The separating device 1 has transverse beams 4 , 5 , 6 arranged one behind the other in a plane. The planes of these beams 4 , 5 , 6 lie above the printing plates 3 on the printing plate pallet 2 .

[0032] The drives 9, 10, 11 for these beams 4, 5, 6 are located at figure 1 In the region of local A.

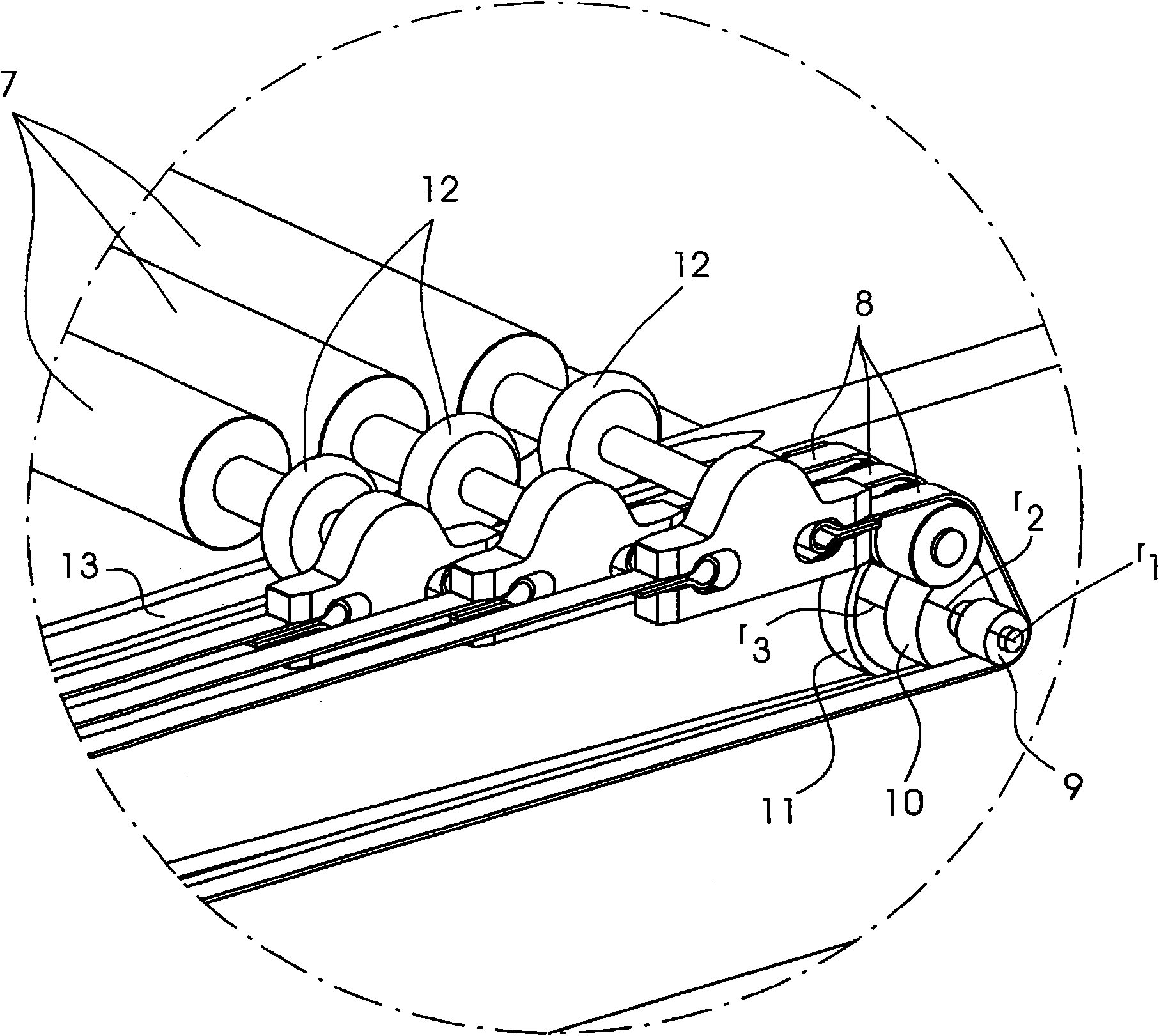

[0033] exist figure 2 shown in detail in figure 1 part of A.

[0034]These crossbeams 4 , 5 , 6 are arranged one behind the other and are driven by a belt 8 . For this purpose, the belts 8 are arranged next to each other in the same plane of movement of the transverse beams 4 , 5 , 6 . These beams 4 , 5 , 6 include rotatable rods 7 for moving under a raised printing plate 3 . In the example shown here, three transverse beams 4 , 5 , 6 with rods 7 are shown. The frontmost cross member 6 is connected via a belt 8 to a first pu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap