Aseptic filling valve

A technology of aseptic filling and valve body, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of large lifting displacement of valve stem mechanical mechanism, easy to bury hidden dangers, uneconomical and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

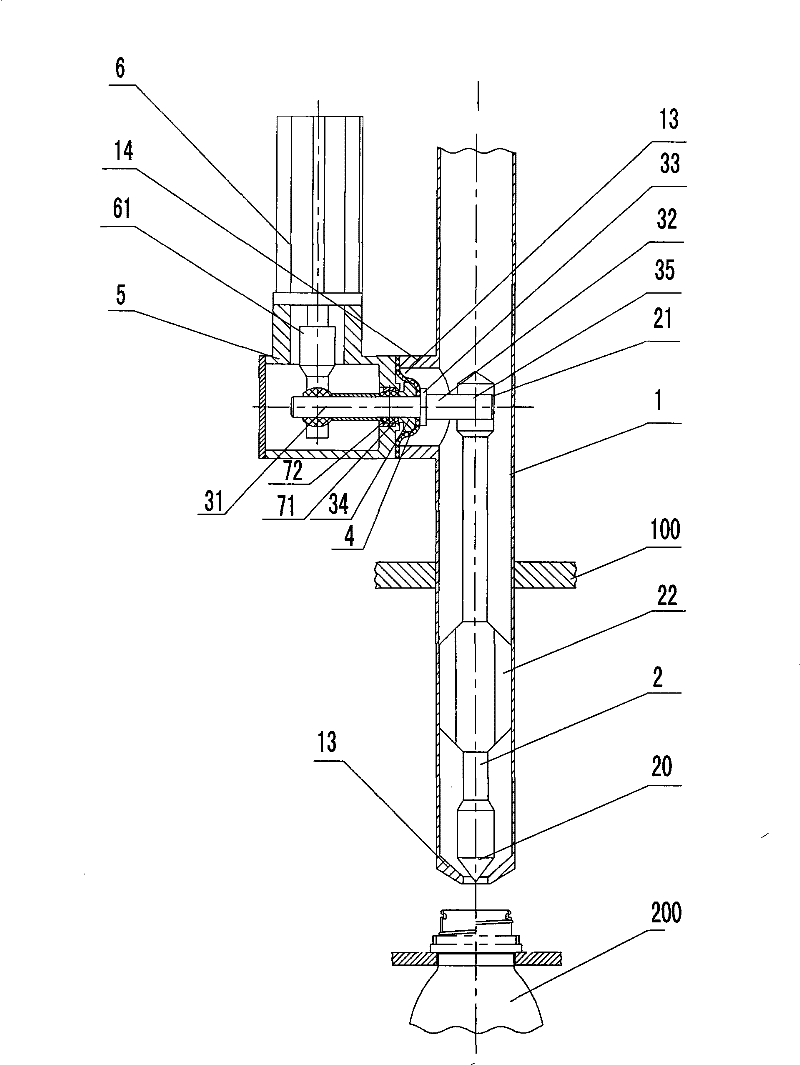

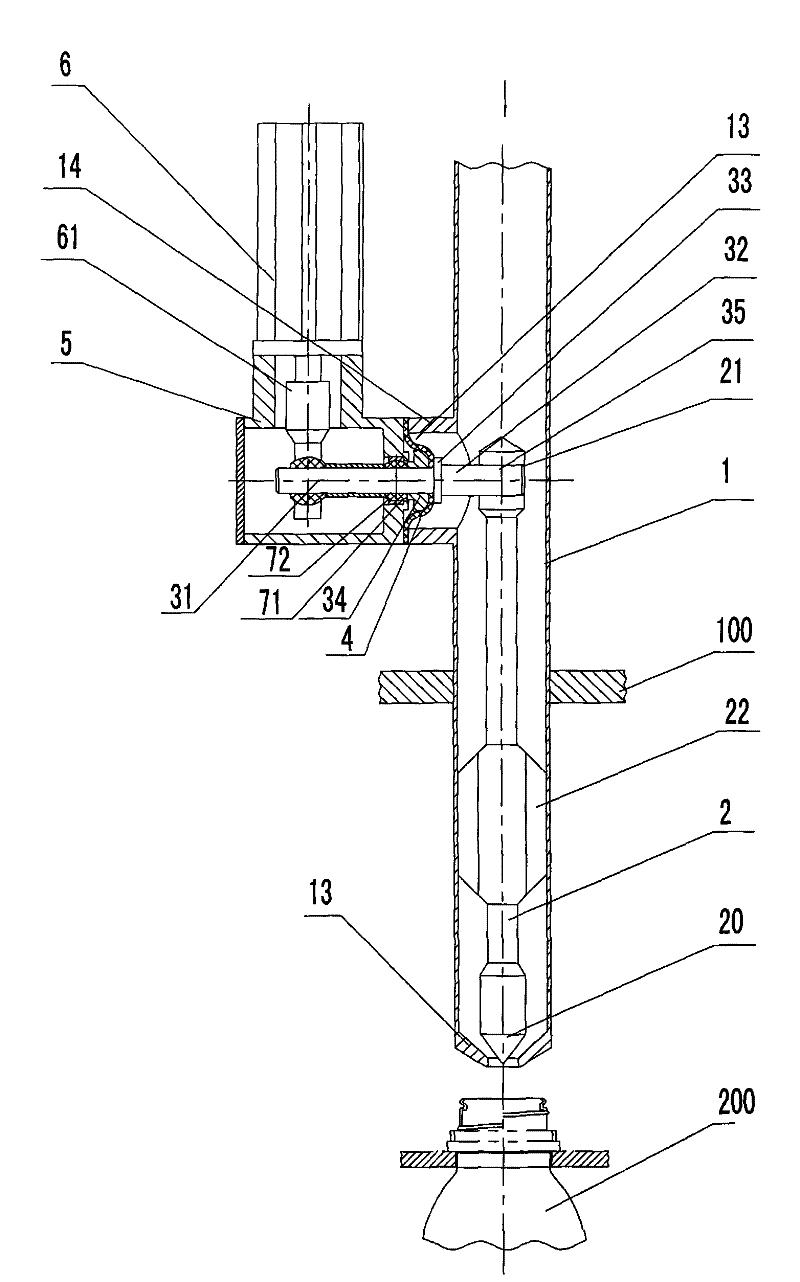

[0005] Refer to attached picture. The present invention includes a valve body 1, a valve stem 2 with a valve core 20, and reference numeral 22 is a guide wing on the valve stem.

[0006] The upper end of the valve body is connected to the liquid storage container that needs to be filled with liquid. For the convenience of installation, manufacturing, aseptic control and disinfection, the valve body includes a split upper valve body and a lower valve body. The upper valve body and the lower valve body are respectively installed on the The bracket 100 is mounted and sealed, and the mounting screw can pass through the bracket from the upper valve body and be threaded with the connecting blind hole of the lower valve body, so as to facilitate aseptic control and disinfection. The lower end of the lower valve body is a valve mouth 13, and the valve core 20 cooperates with the valve mouth 13 to realize the switch of the filling valve.

[0007] The present invention is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com