Shell deformation fuel injector for engine

A technology of engines and injectors, which is applied to engine components, machines/engines, fuel injection devices, etc., to achieve the effects of good temperature resistance, accurate fuel injection volume, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

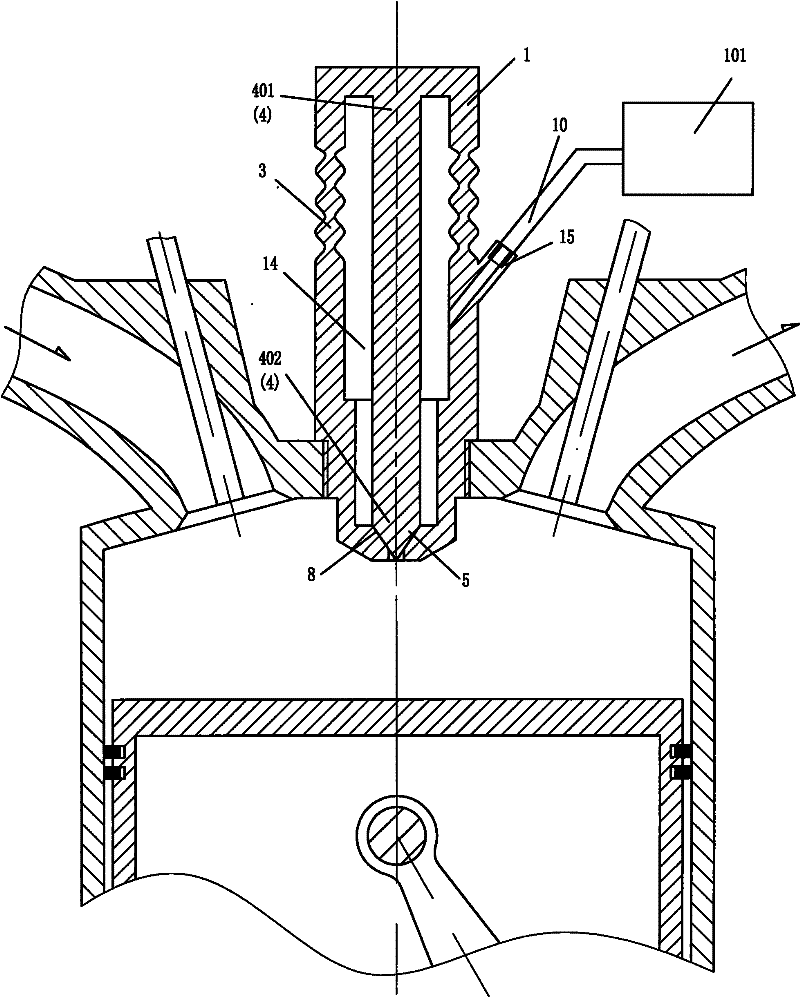

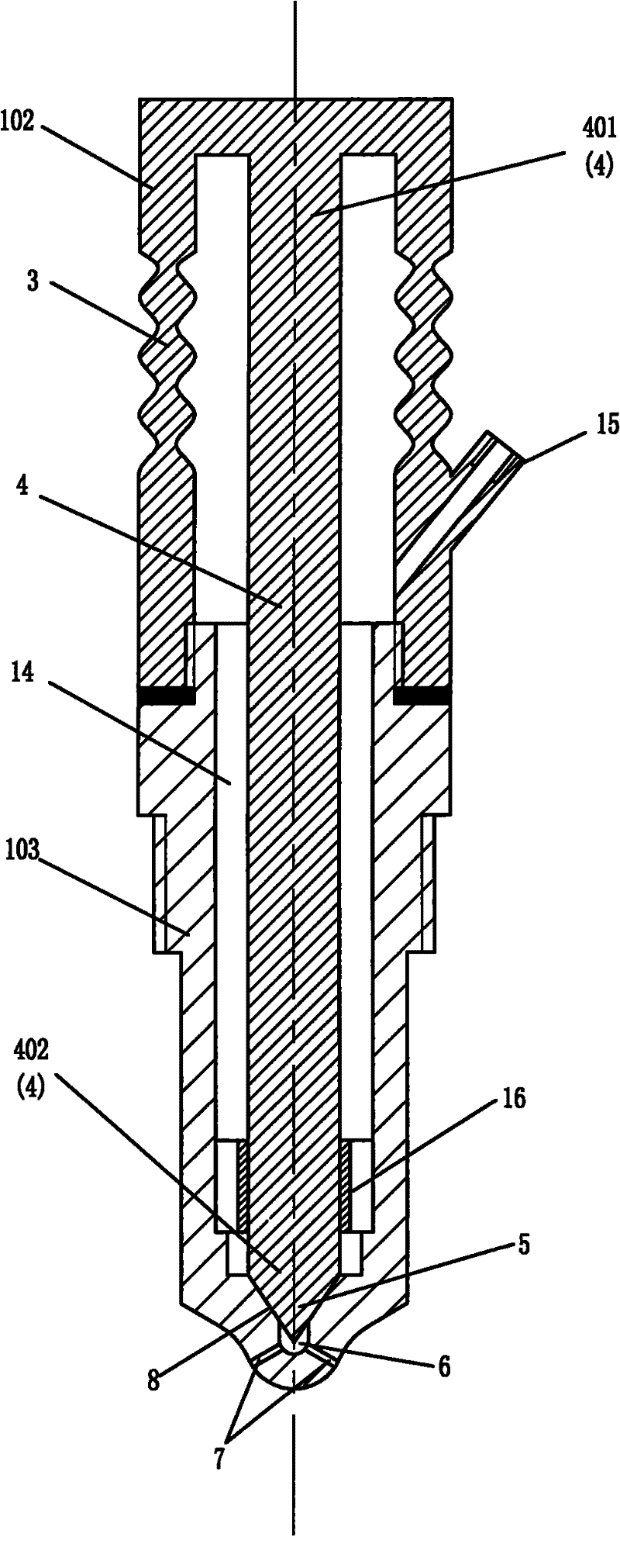

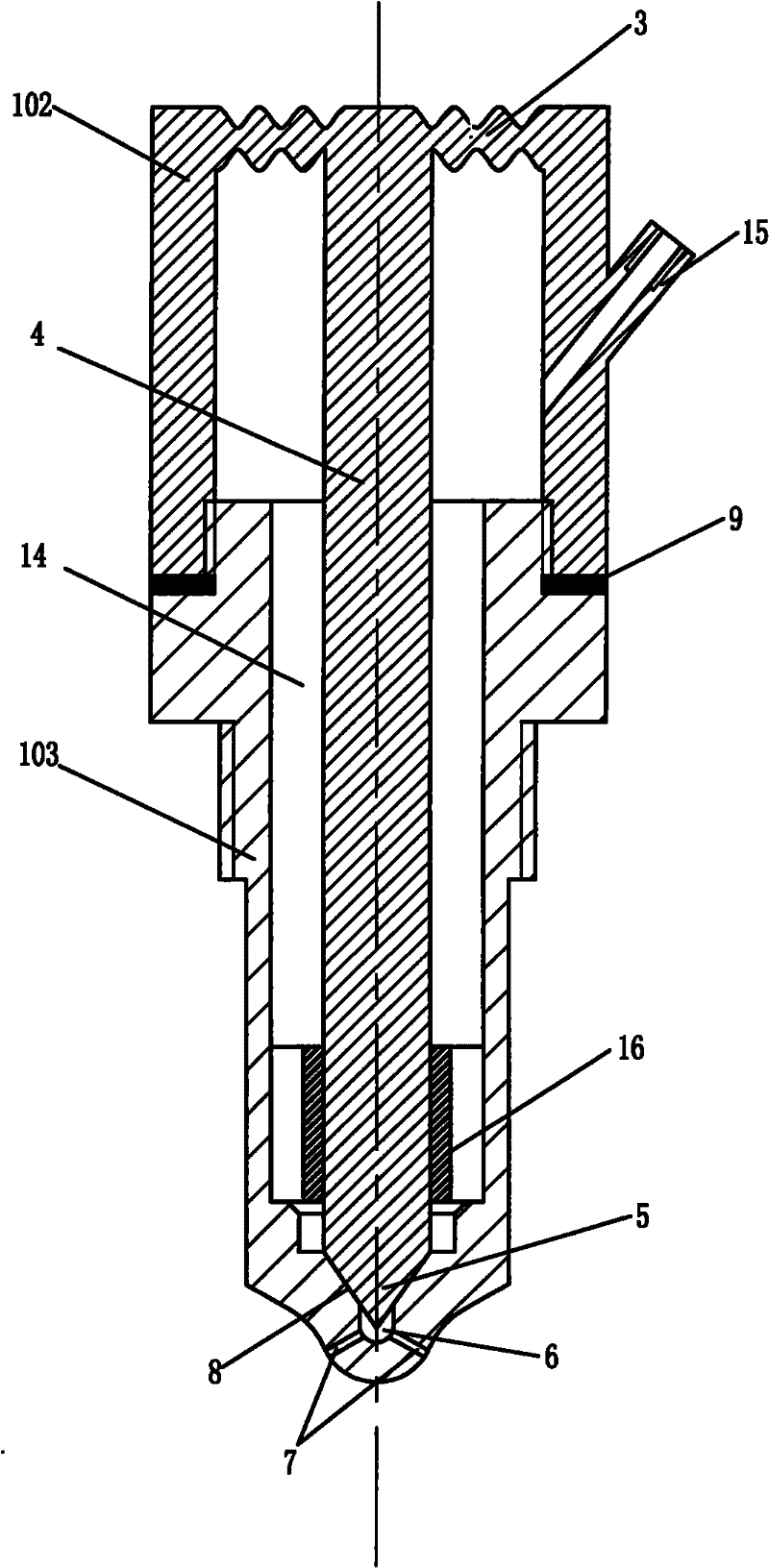

[0039] The present invention will be further described below in conjunction with accompanying drawing, please refer to figure 1 The shown casing deformed fuel injector for an engine includes: a closed casing 1 and an oil inlet port 15 . A valve body 4 is provided in the inner cavity 14 of the closed casing 1, and one end 401 of the valve body 4 is connected with one end of the closed casing 1, and a valve is arranged at the other end of the closed casing 1. hole 8, the other end 402 of the valve body 4 is provided with a valve head 5, the valve head 5 can seal and close the valve hole 8, and can also open the valve hole 8, the valve head 5 and the valve hole 8 The matching surface of the valve hole 8 is set as a plane, a conical surface or a curved surface, and at least one elastic region 3 is provided on the closed shell 1, and the inner cavity 14 of the closed shell 1 is directly or indirectly connected to the The fuel inlet port 15 is in communication with the timing puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com