Shell deformation fuel injector for novel engine

A technology of engines and injectors, which is applied in the direction of engine components, machines/engines, fuel injection devices, etc., can solve problems such as fuel leakage, complicated manufacturing process, and high manufacturing cost, and achieve accurate fuel injection, fast injection response, and temperature resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

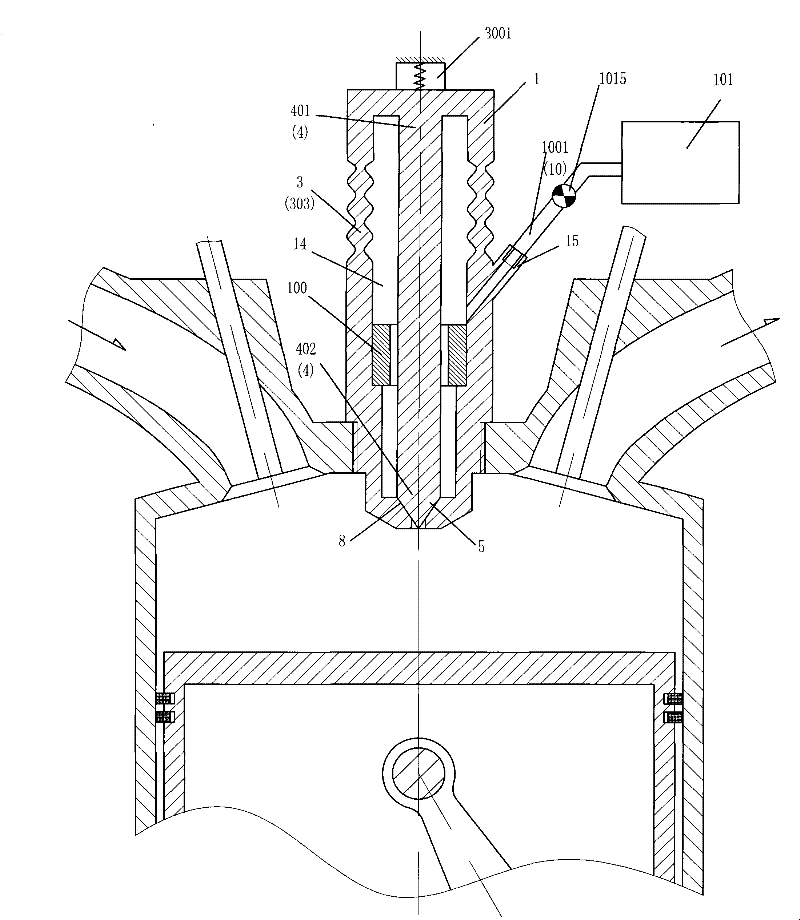

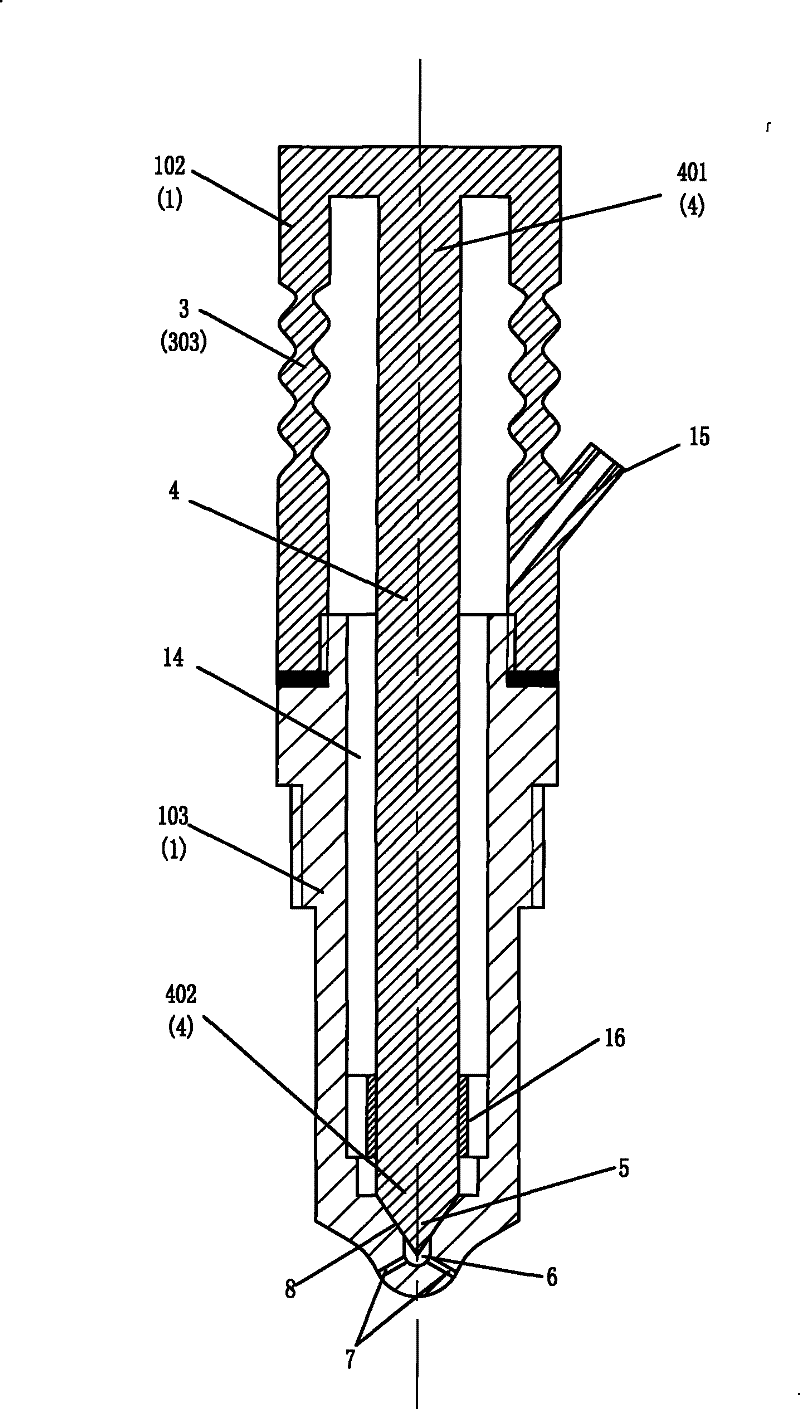

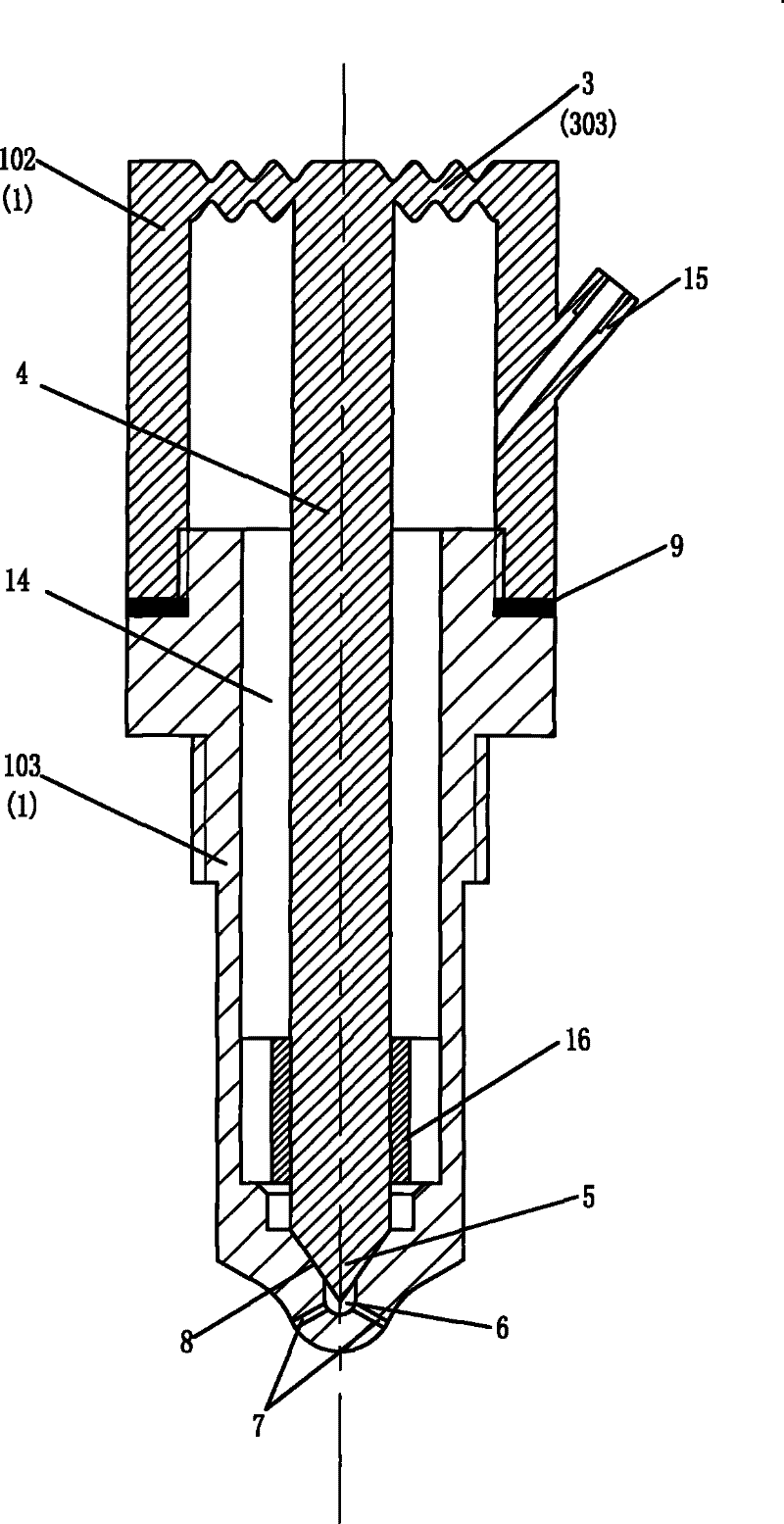

[0041] Figure number

[0042] 1. Closed shell 102. Upper shell 103. Lower shell 3. Elastic zone

[0043] 4. Valve body 401. One end 402. The other end 5. Inner opening valve head

[0044] 6. Fuel distribution area 7. Fuel injection hole 8. Inner opening valve hole 9. Adjusting gasket

[0045] 10. Oil pipe 101. Timing pulse fuel source 14. Inner cavity 15. Oil inlet port

[0046] 16. Guide structure 17. Compression nut 18. Inner ball 19. Outer ball

[0047] 20. Ball joint screw 21. Anti-overexpansion jackscrew 1015. Control valve 901. Disc spring

[0048] 902. Pressure adjustment spring 201. Inner open cone-cylindrical combined mating surface

[0049] 202. Inner open different cone angle double cone combined mating surface 203. Planar mating surface

[0050] 100. Hard volume 5001. Surface fuel injection holes 303. Deformation zone

[0051] 3001. Deformation control device 3033. Radial deformation limiting structure

[0052] 1001. Rigid oil pipe 1015. Oil return interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com