Gas pulse timing vibration source fuel injector for engine

A technology of engine and injector, which is applied in the direction of engine components, engine control, low-pressure fuel injection, etc., can solve the problems of restricting engine efficiency and environmental protection performance, slow injection response, high manufacturing cost, etc., and achieves simple structure, accurate fuel injection quantity, Effects of improving efficiency and low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

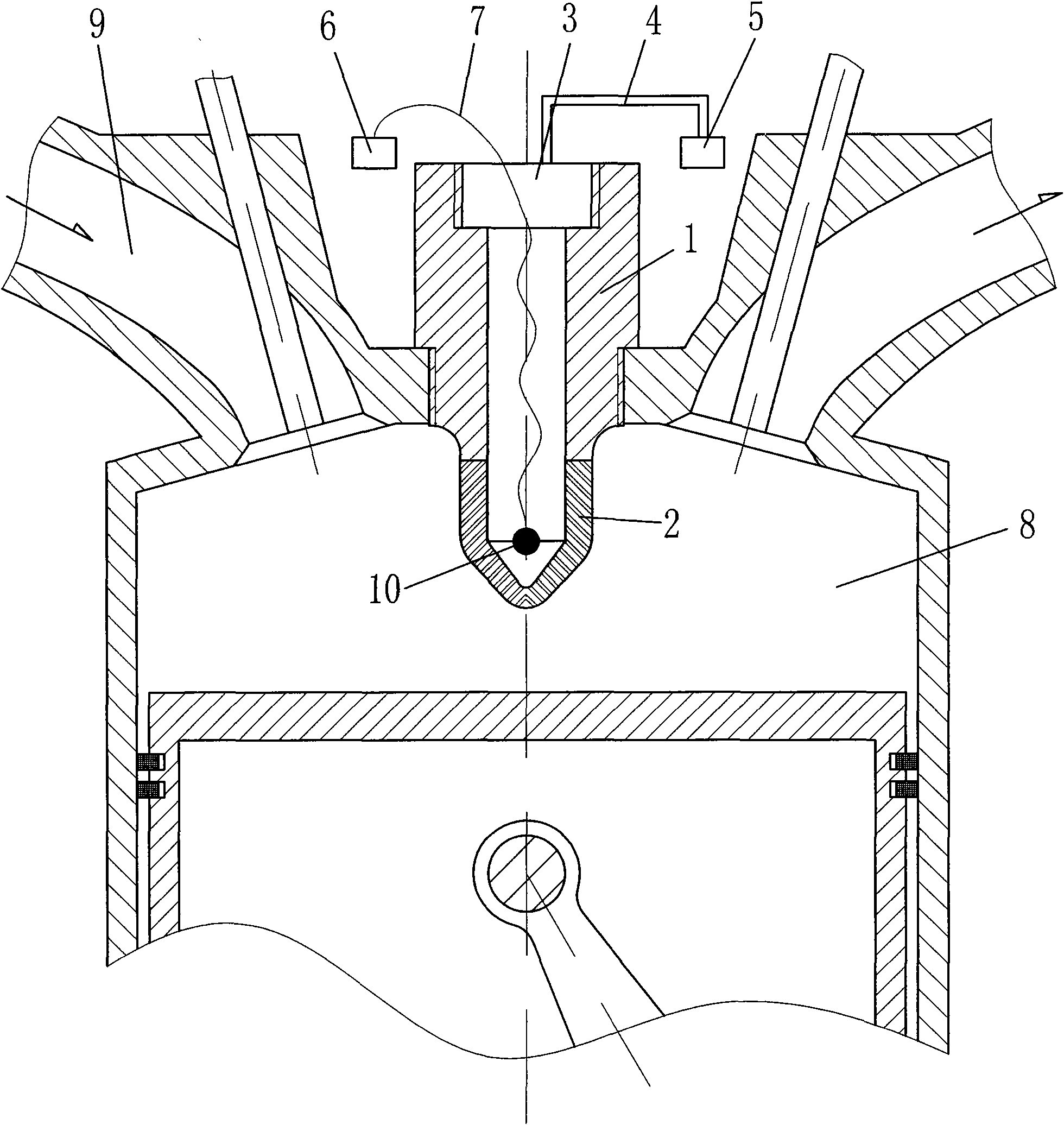

[0032] The present invention will be further described below in conjunction with accompanying drawing, please refer to figure 1 The gas-phase pulse timing seismic source fuel injector for the engine shown includes a housing 1 , an injection area 2 and an oil inlet port 3 . The housing 1 communicates directly or indirectly with the injection area 2, the housing 1 communicates with the oil inlet port 3, and the oil inlet port 3 communicates with the oil pump 5 through the oil pipe 4. In the housing 1 A gas-phase pulse timing seismic source 10 is arranged inside and / or in the oil pipe 4, and the gas-phase pulse timing seismic source 10 communicates with the timing energy supplier 6 through a passage 7, and the gas-phase pulse timing seismic source 10 is directly or indirectly connected to the The housing 1 is connected, and the gas-phase pulse timing source fuel injector is set in the cylinder 8 and / or in the intake passage 9 .

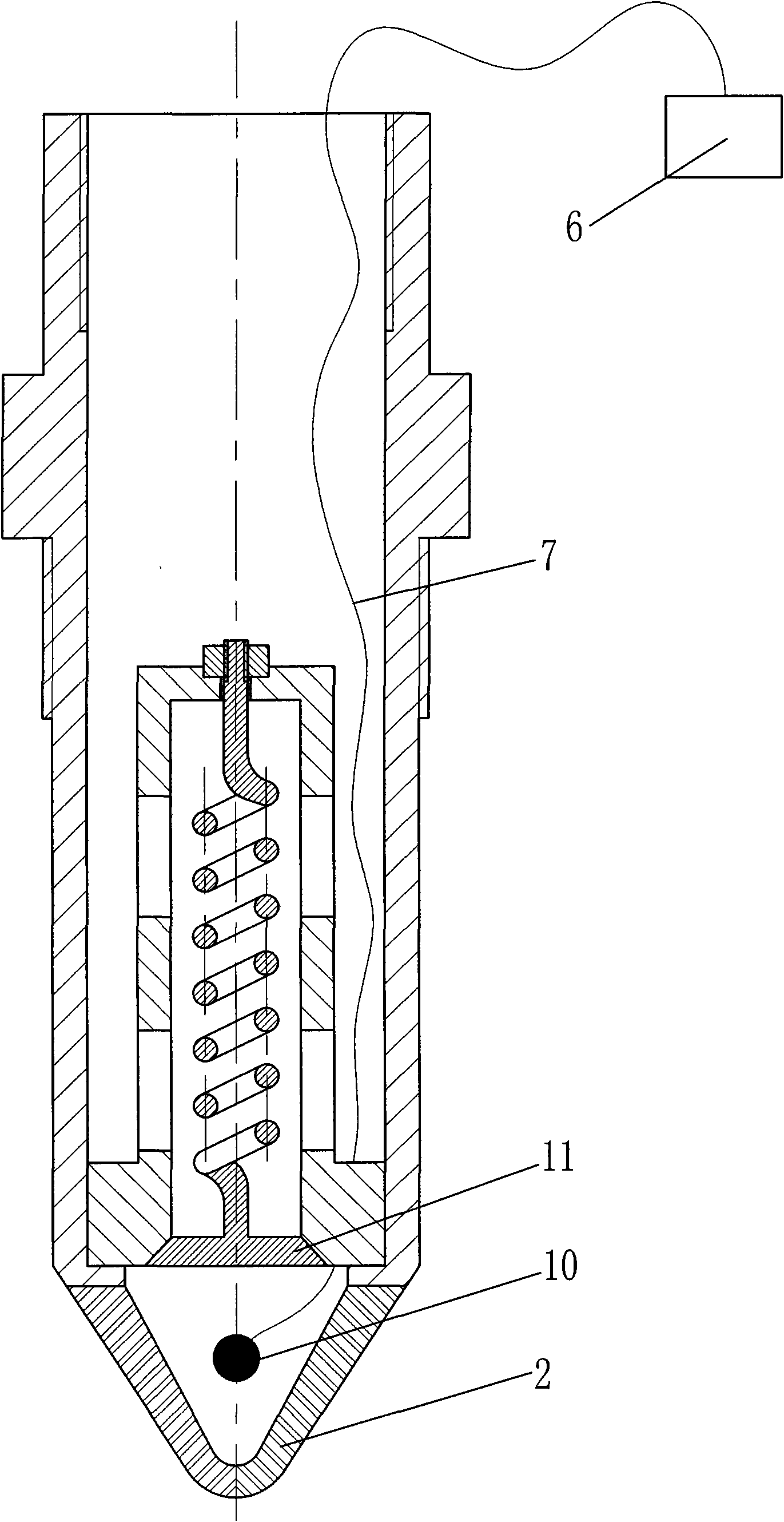

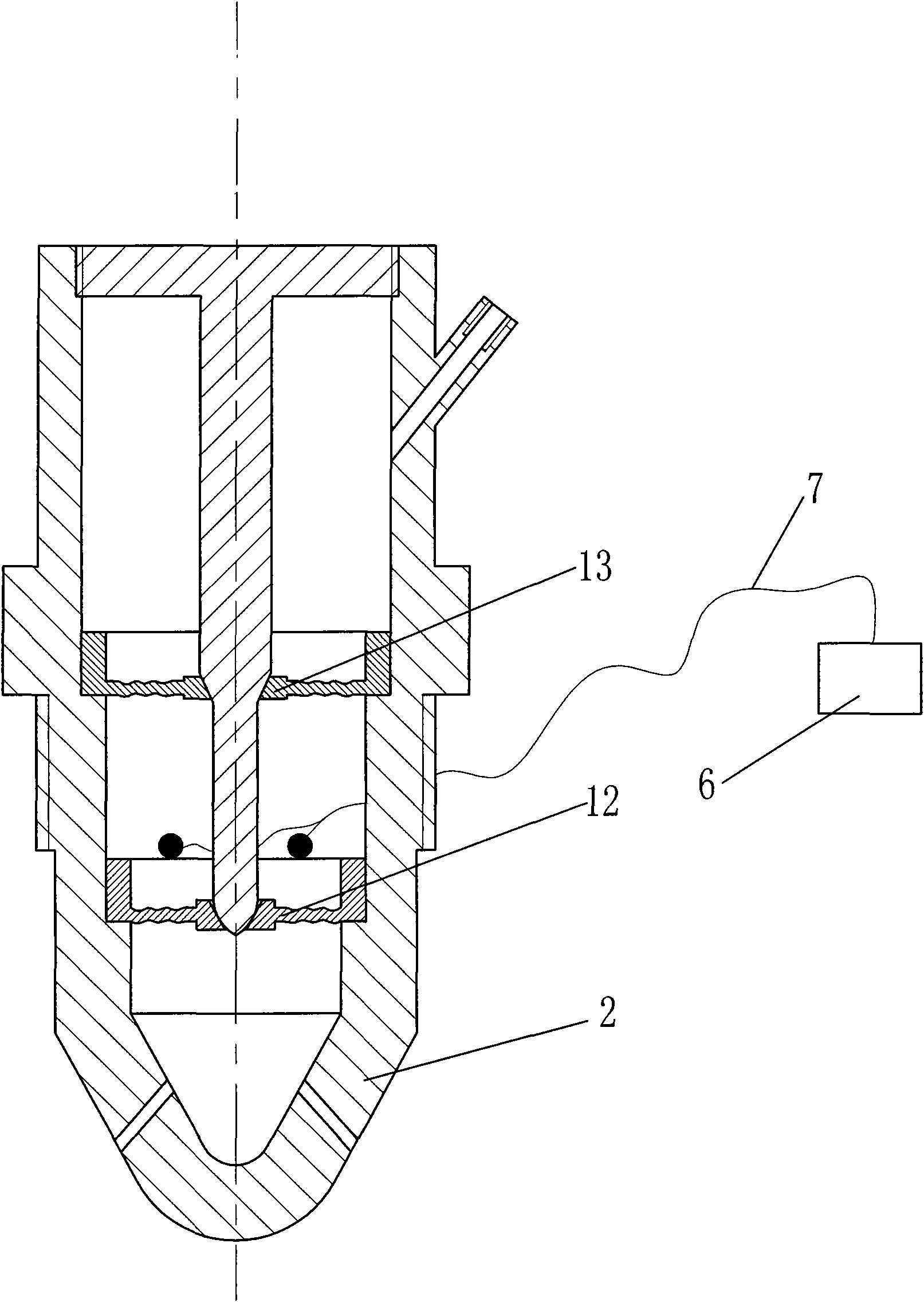

[0033] See figure 2 In the gas-phase pulse timi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com