Directly controlled shell body deformation fluid ejector for engine

A fluid injector, engine technology, applied in engine components, machines/engines, fuel injection devices, etc., to achieve the effects of good temperature resistance, fast injection response, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

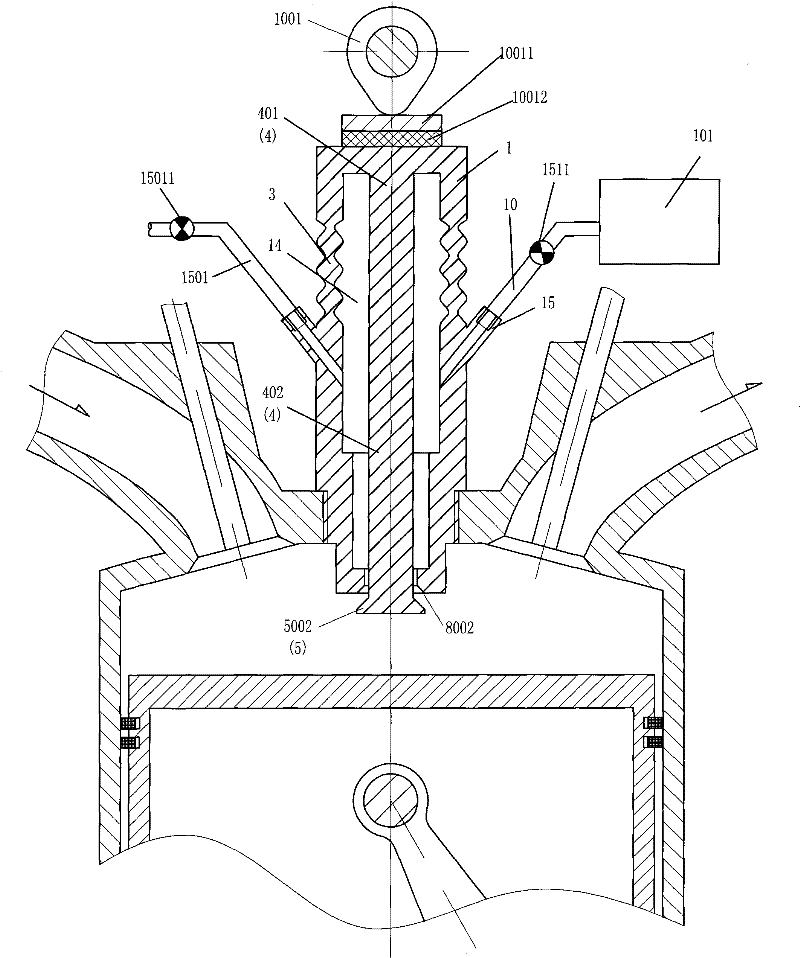

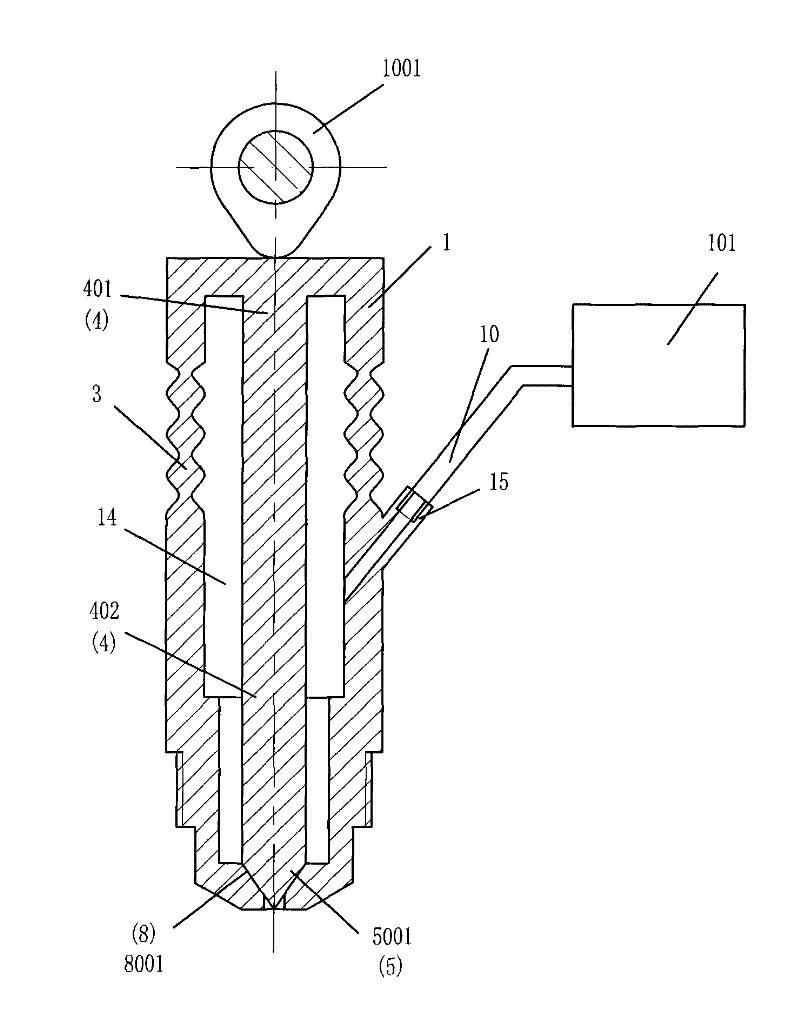

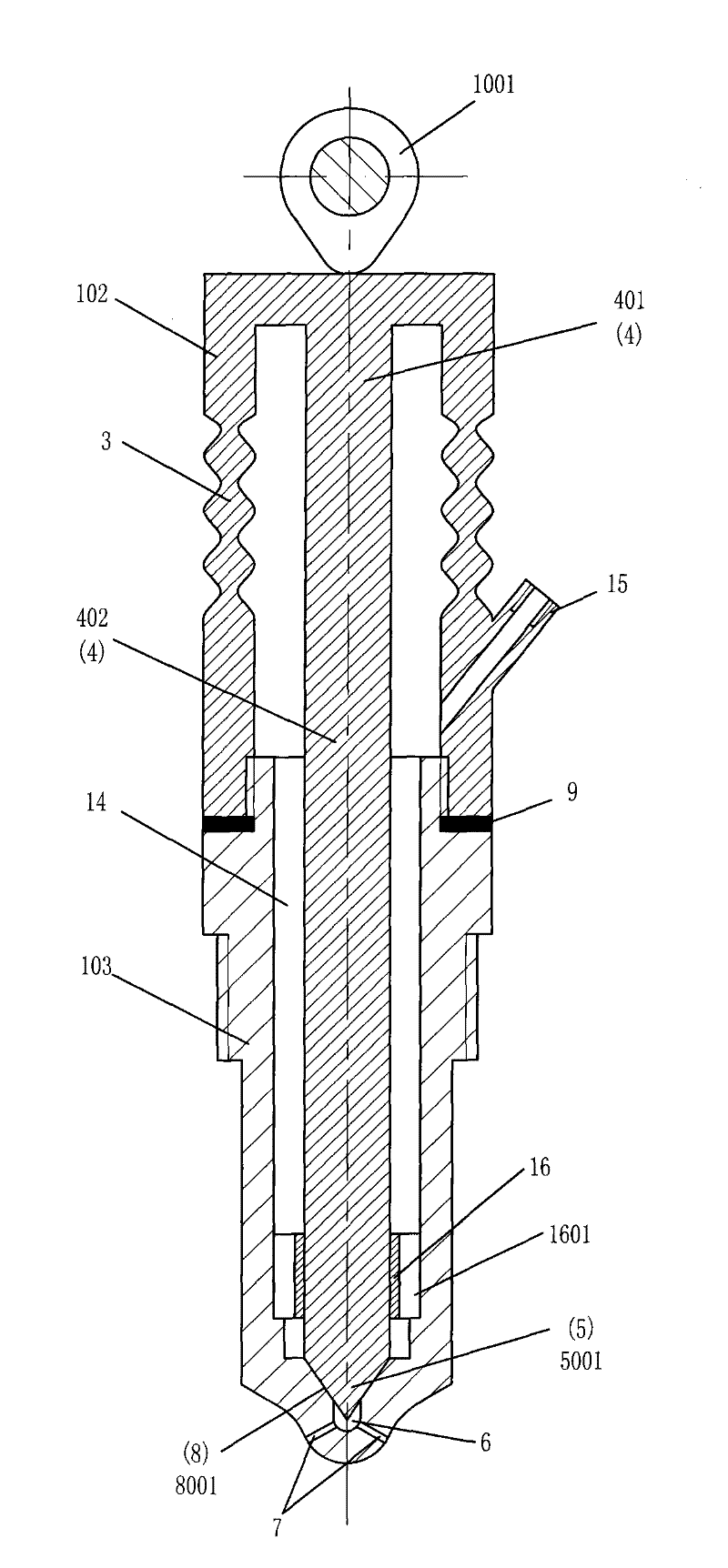

[0048] Figure number

[0049] 1. Closed shell 102. Upper shell 103. Lower shell 3. Elastic zone

[0050] 4. Valve body 401. Valve tail 402. Valve stem 4011. Disc valve tail

[0051] 4012. Fluid through hole 5. Valve head 5001. Inward opening valve head 5002. External opening valve head

[0052] 6. Fluid Distribution Area 7. Fluid Injection Orifice 8. Valve Orifice

[0053] 8001. Inward opening valve hole 8002. External opening valve hole 9. Adjusting gasket

[0054] 10. Fluid introduction tube 101. High pressure fluid source 14. Inner cavity

[0055] 15. Fluid inlet port 16. Guide structure 17. Compression nut

[0056] 18. Inward catching 19. Outward catching 1001. Control mechanism

[0057] 4401. Card slot 4402. Card plate 1601. Guide structure fluid channel

[0058] 1501. Fluid export interface 8003. Flow diversion structure 1511. Fluid import control valve

[0059] 1021. Upper head 1022. Lower head 15011. Fluid export control valve

[0060] 3001. End seal elastic zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com