Electric disk brake

A disc brake, electric technology, applied in the direction of brake type, brake components, brake actuators, etc., can solve the problems of large-scale deceleration mechanism, can not meet the increase of output, etc., to achieve the effect of large thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

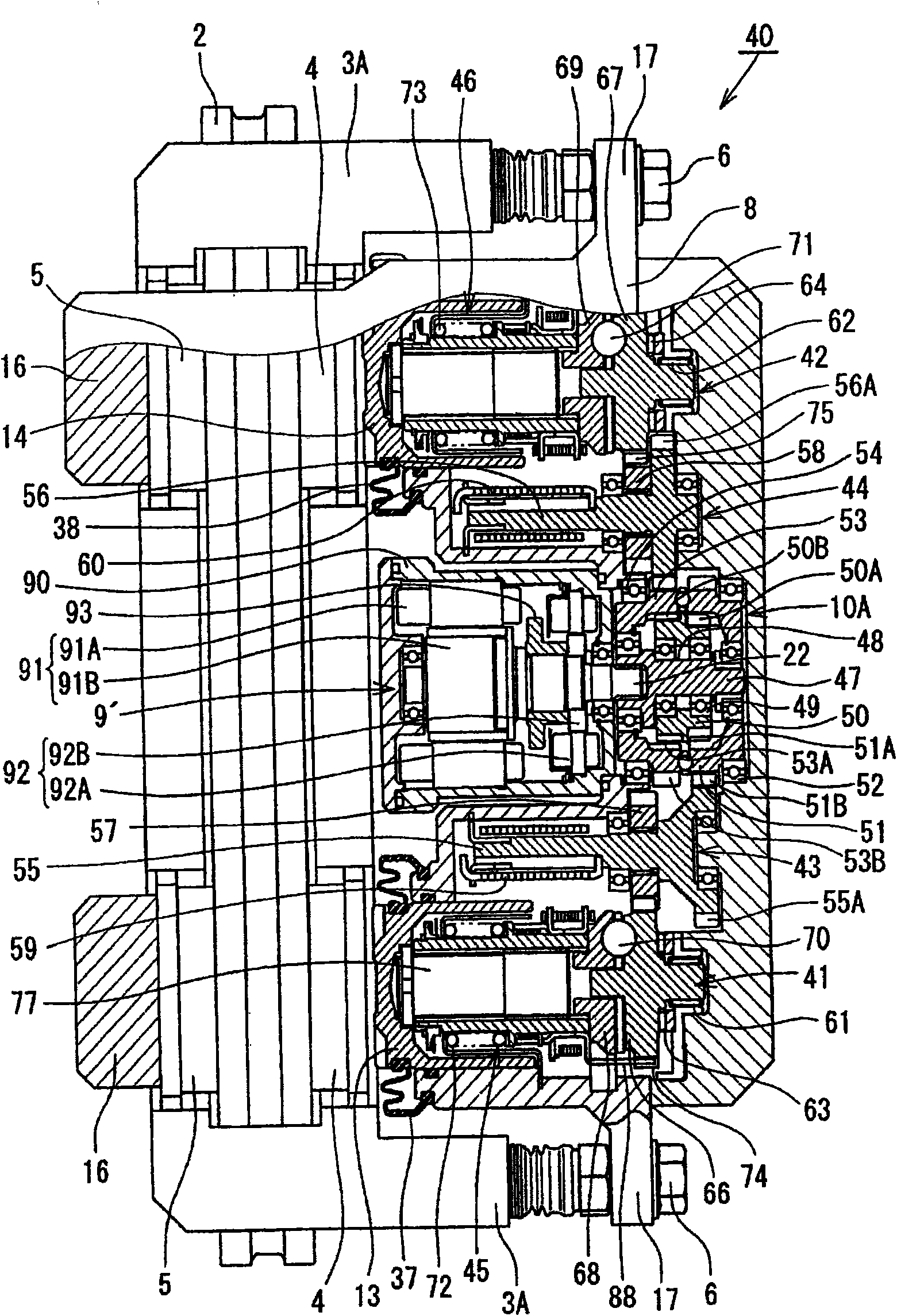

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

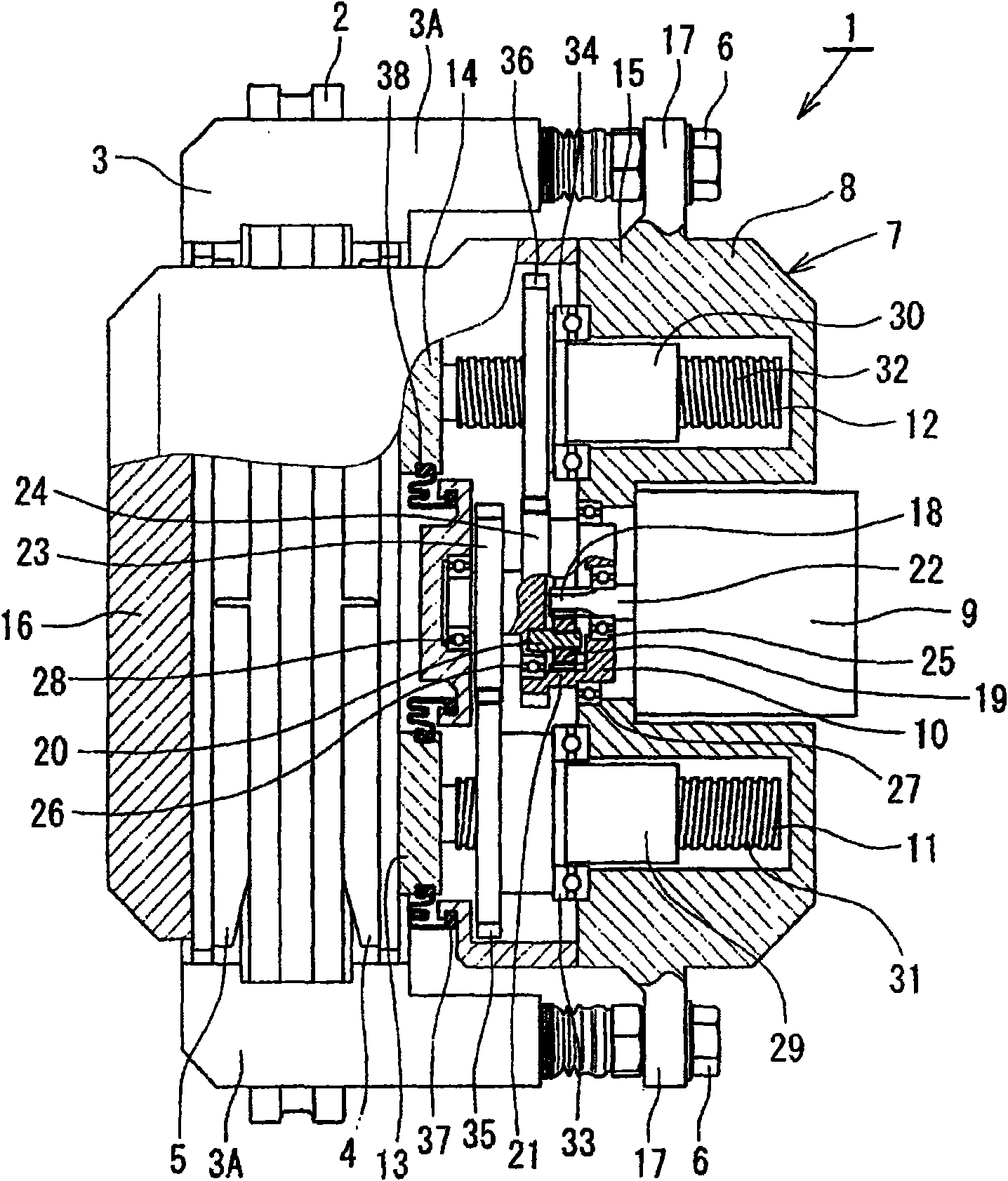

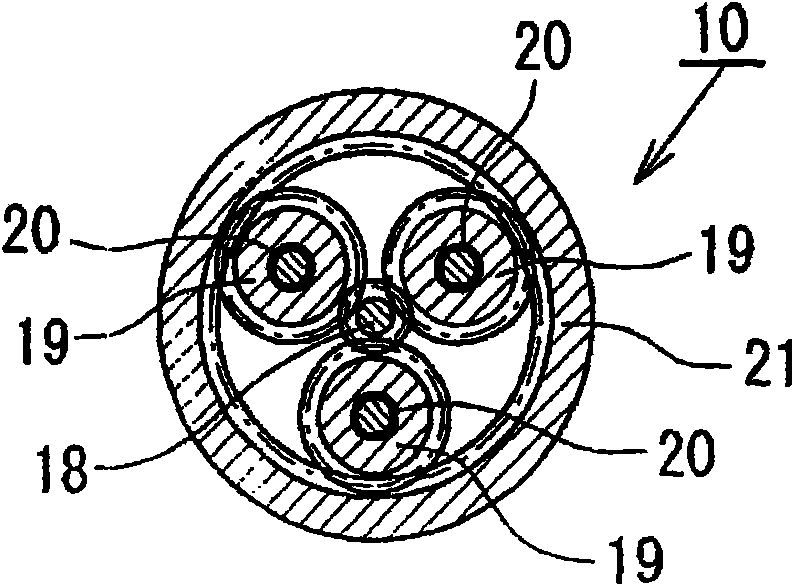

[0024] For the first embodiment of the present invention, refer to figure 1 and figure 2 Be explained. Such as figure 1 As shown, the electric disc brake 1 of this embodiment is a caliper floating type disc brake, and includes: a disc rotor 2 that rotates together with the wheel; (not shown); a pair of brake blocks 4, 5, which are arranged on both sides of the disc rotor 2 and supported by the bracket 3; electric pliers 7, which are arranged in a manner straddling the disc rotor 2, and pass A pair of slide pins 6 , 6 is supported by a pair of arm portions 3A, 3A of the bracket 3 so as to be movable in the axial direction of the disk rotor 2 .

[0025] The electric pliers 7 are assembled with the following elements on the pliers main body 8, namely, a motor / control unit 9 (electric motor), a speed reduction mechanism 10, a pair of ball screw mechanisms 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com