Retarded adhesive prestressed steel bar outer wrapped jacket extrusion forming machine

A slow-bonding prestressing and extruding molding machine technology, which is applied in the field of slow-bonding prestressed steel sheath extrusion molding machine, can solve the problem of dripping, too little slow-gelling adhesive, and the influence of slow-bonding prestressed steel bars Quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For the convenience of further understanding the purpose means of the present invention, hereby attach preferred embodiment figure to describe in detail as follows:

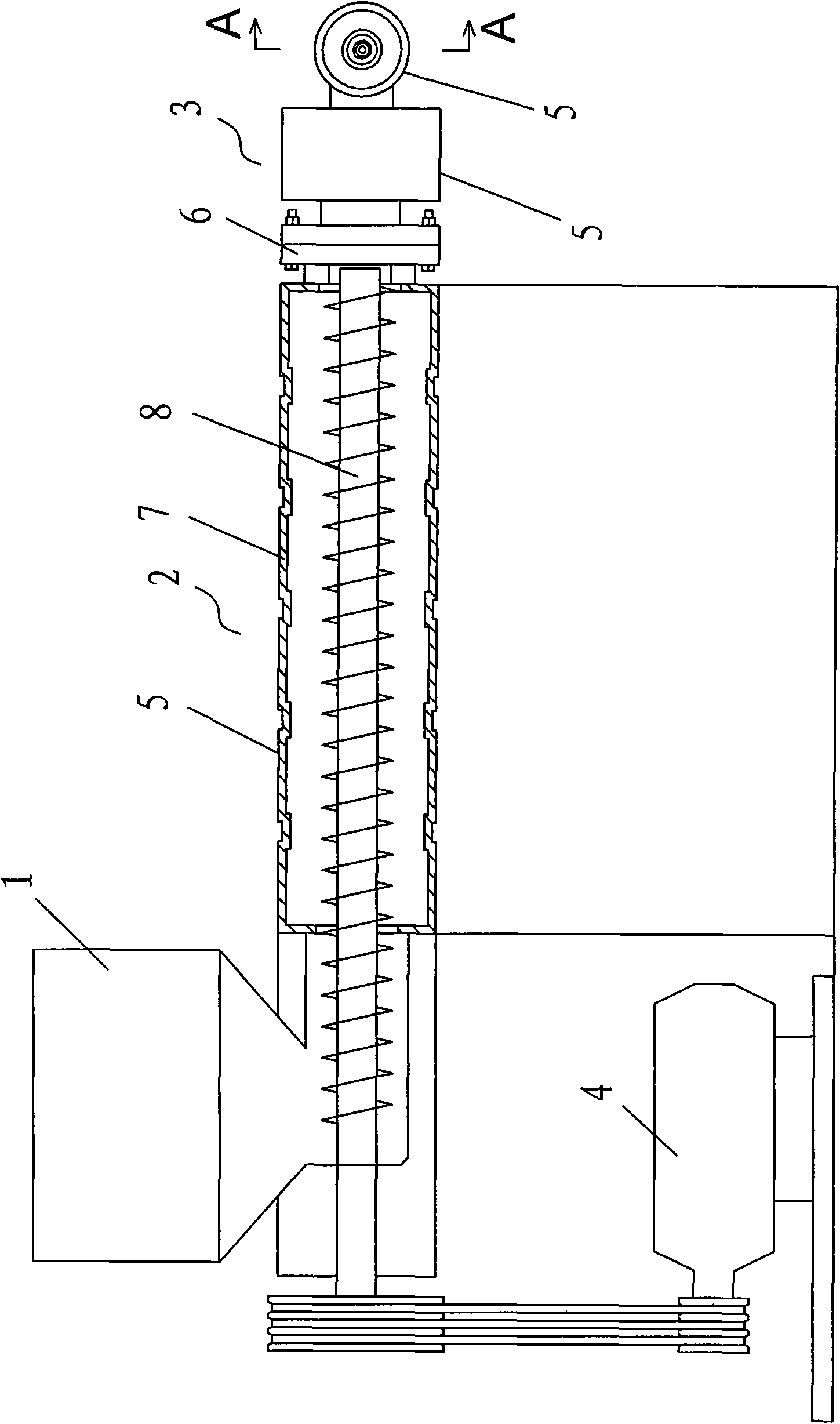

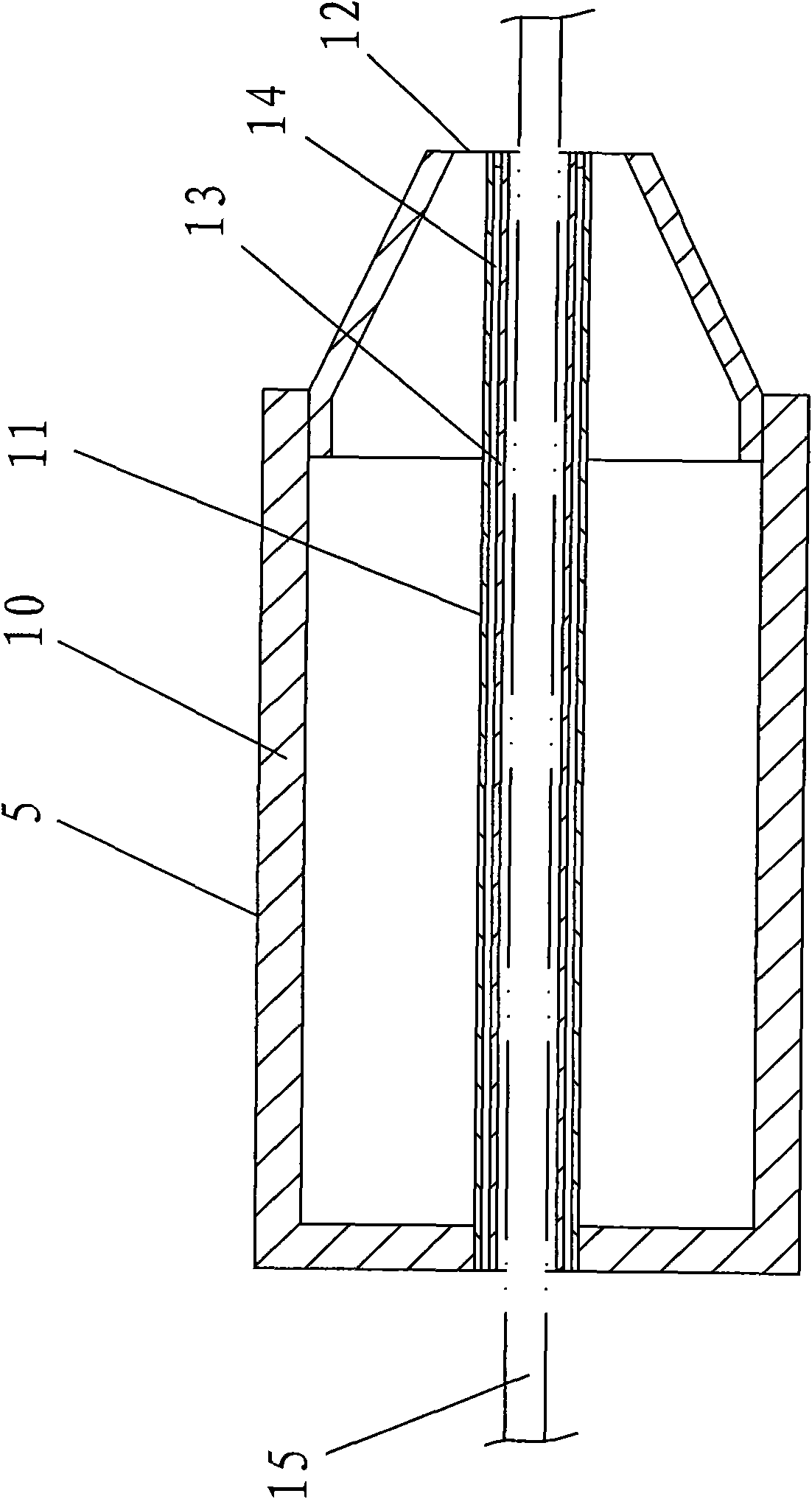

[0019] Such as figure 1 , figure 2 Shown, the present invention a kind of slow bonded prestressed steel bar sheath extrusion molding machine, it is characterized in that, it comprises: hopper 1, machine body 2, machine head 3 and motor 4, the outer surface of machine body and machine head is respectively provided with There is a heating jacket 5, and the body and the head are connected by a flange 6; the body 2 includes a barrel 7 and a screw 8 arranged in the barrel 7, the screw 8 is connected with the motor 4 through a pulley and a belt, and the head 3 is Forming a T-shape, the machine head 3 is composed of a mold casing 10 and a cylindrical mold core 11 fixedly connected in the mold casing 10 and perpendicular to the body 2. An annular opening 12 is formed between the outlet of the mold casing and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com