Biomass supercritical water gasification hydrogen production absorption reactor thermally driven by solar energy

A supercritical water gasification and solar energy absorption technology, which is applied in the production of hydrogen, chemical instruments and methods, hydrogen, etc., can solve the problems that have not been reported in the relevant reports, and achieve the effect of concentrating light, reducing heat loss, and heat flux distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

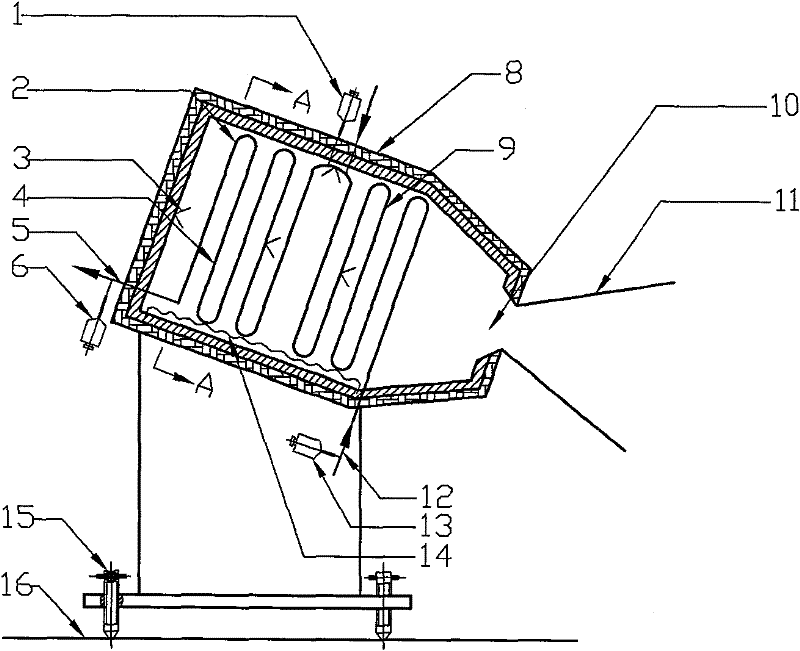

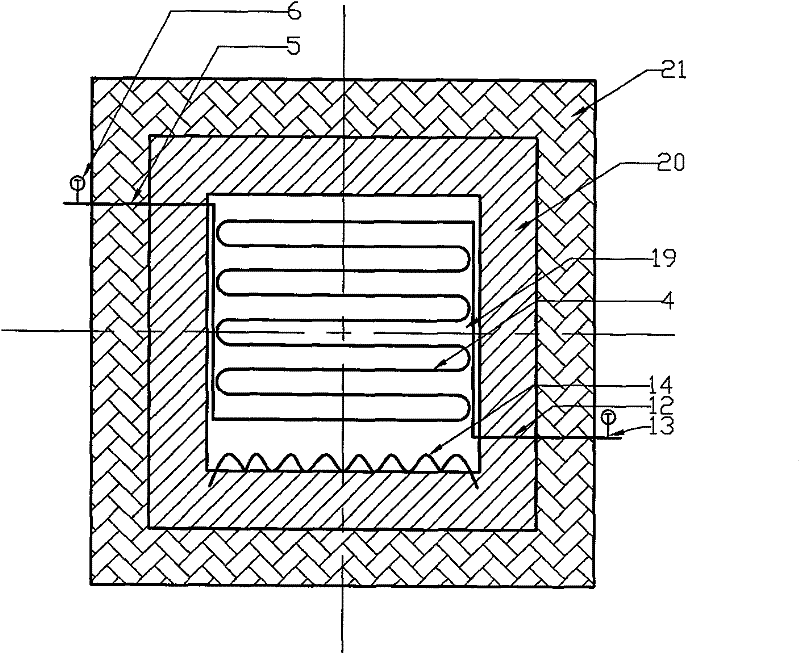

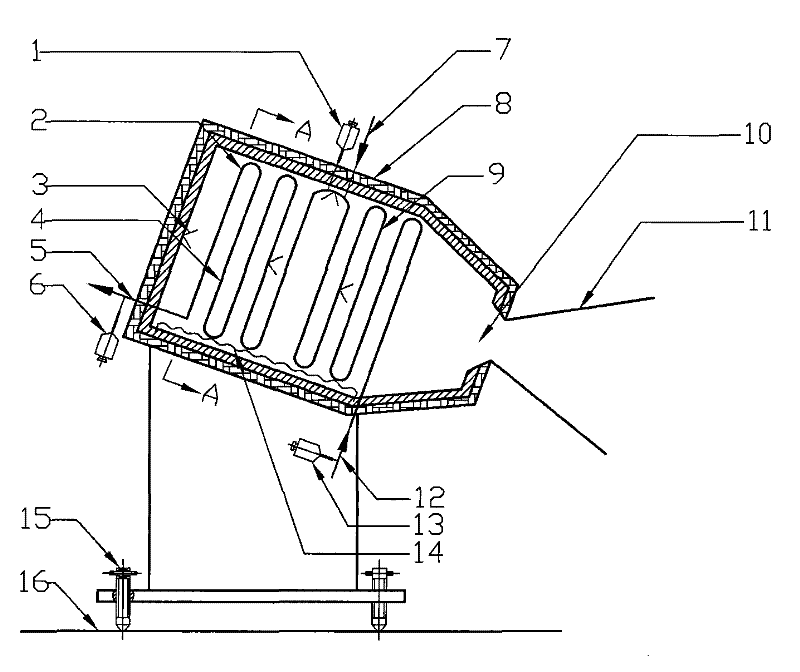

[0038] Example: Using 0.2 mol / L glucose as a biomass model compound, a biomass supercritical water gasification hydrogen production experiment was carried out in the absorption reactor. Experimental location: Xi'an, 108°55' east longitude, 34°15' north latitude, the average direct solar radiation intensity of the day was 720w / m 2 The tube length of the serpentine tube flow reactor is 30m, and the length ratio of the preheating section and the reaction section is 0.6; the mass flow rates of the preheated water and the biomass raw material slurry are 3.6kg / h and 1.2kg / h respectively; the fluid pressure in the reactor is 24MPa; the diameter of the daylight opening of the solar absorber cavity is 250mm; the inclination angle of the solar absorber is 19.4°. Under the above conditions, the reactor achieves continuous and high-efficiency hydrogen production, the gasification rate of glucose exceeds 110%, the highest carbon gasification rate exceeds 77%, and the volume concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com