Solar heat harnessing system

A solar heat transfer system technology, applied in the field of solar heat utilization systems, can solve the problems of heat collector 70 design, manufacture, maintenance troubles, increase costs, etc., to achieve easy manufacture and maintenance, reduce strength and machine capacity, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

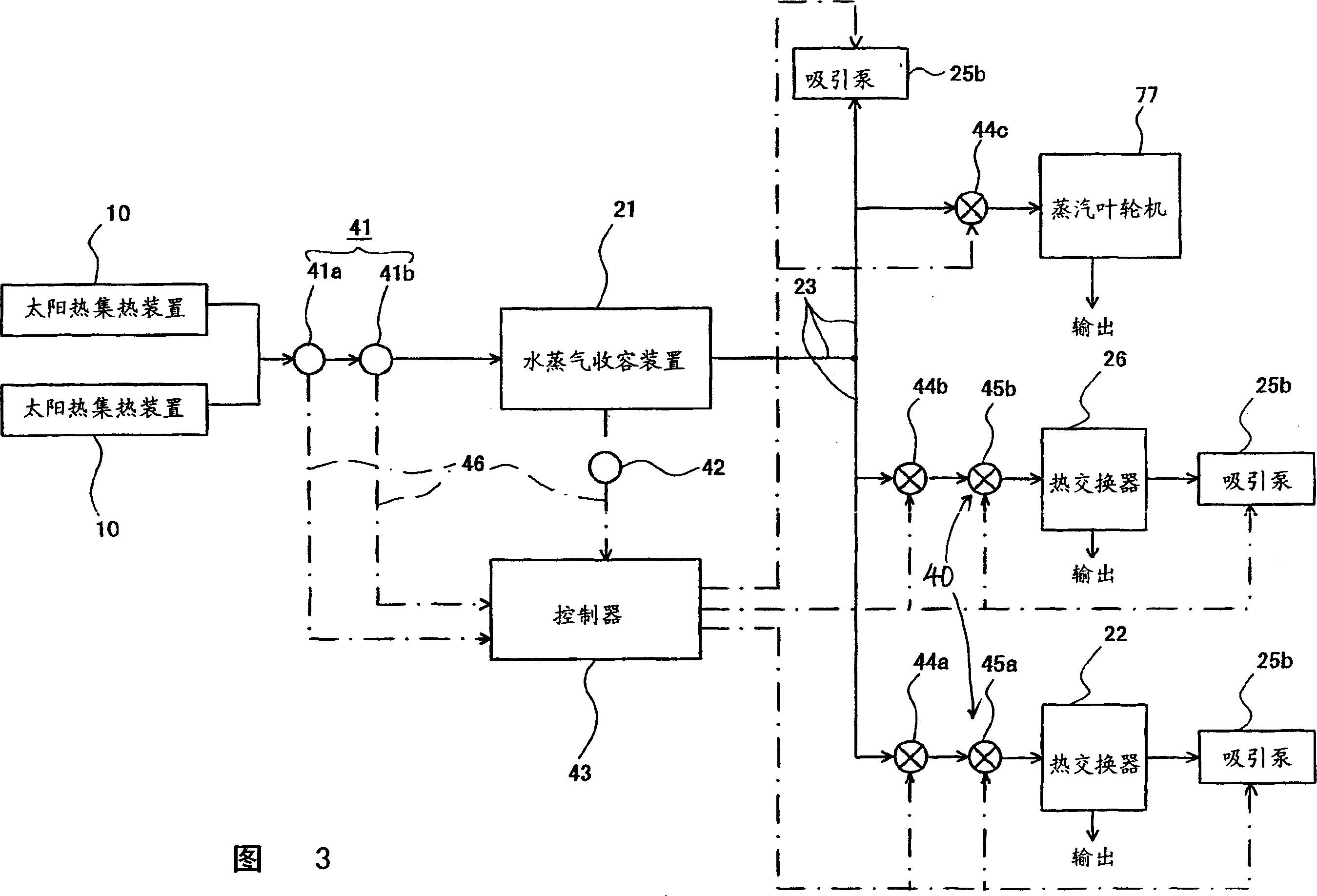

[0053] Hereinafter, embodiments of the solar heat utilization system according to the present invention will be described with reference to the drawings. Also, the same symbols are used for components that have the same function as the previous system.

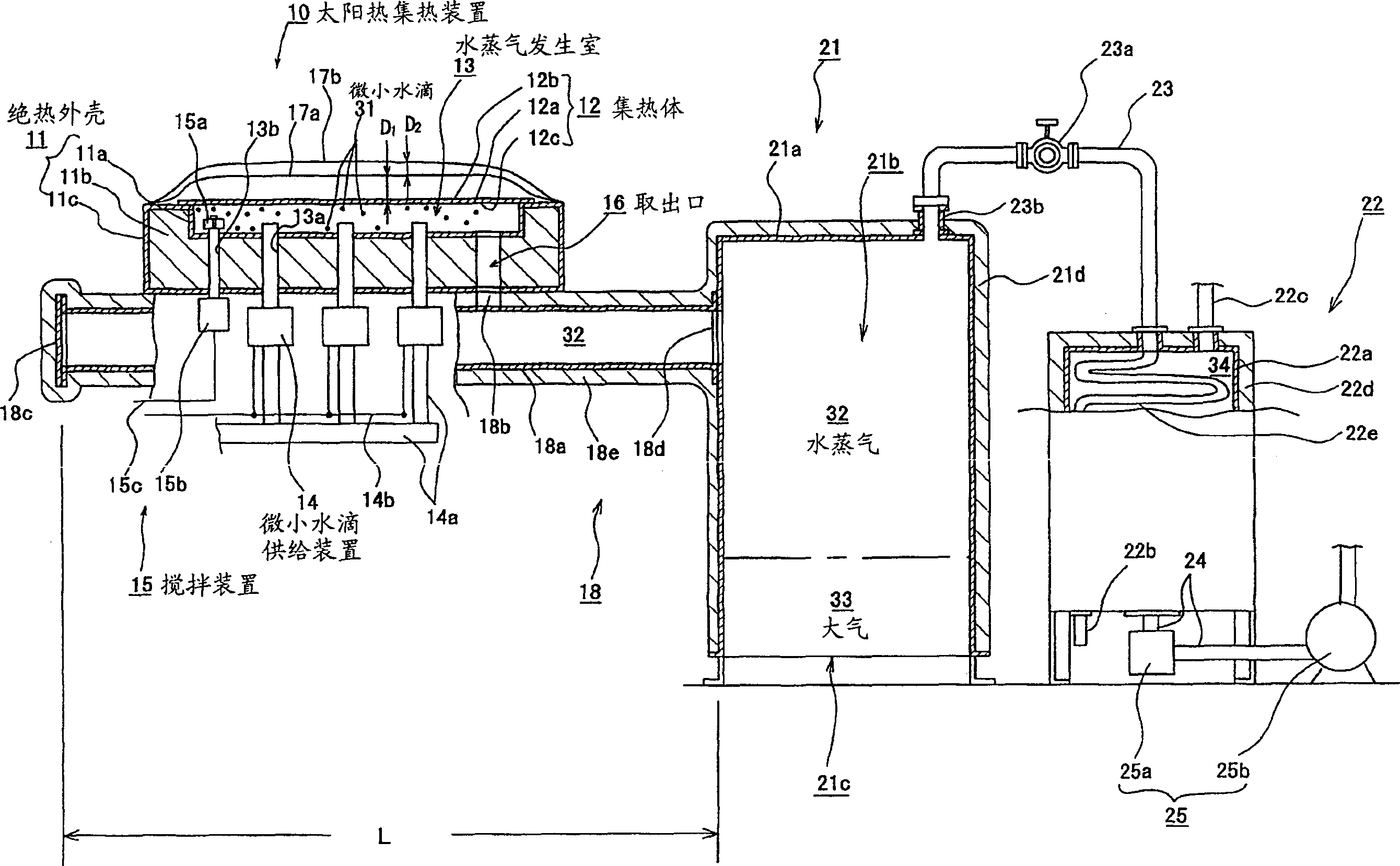

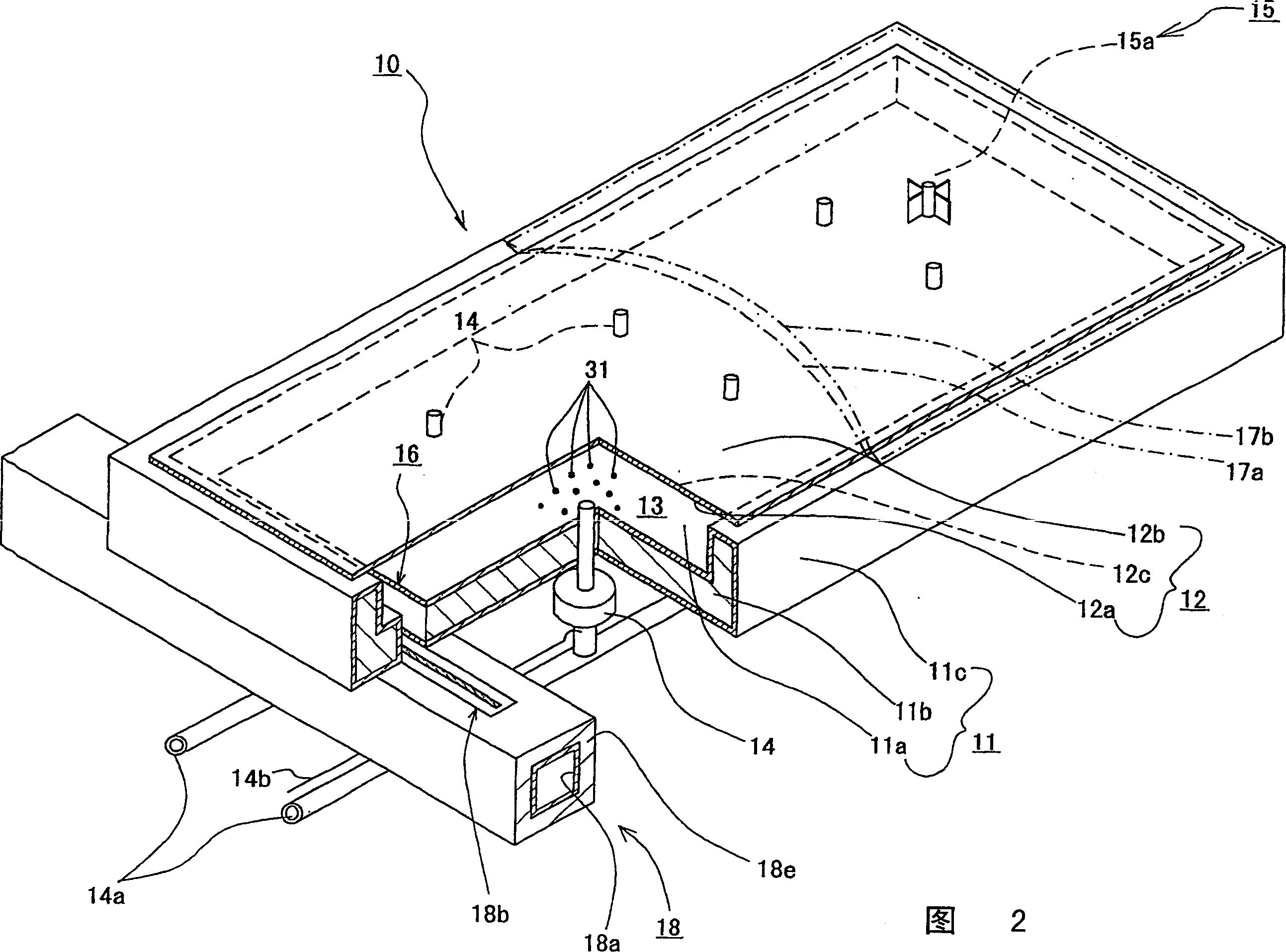

[0054] figure 1 It is a sectional view schematically showing the solar heat utilization system according to the embodiment (1), and Fig. 2 is a partial sectional oblique view showing in detail the vicinity of the heat collector of the solar heat utilization system according to the embodiment (1). The frame 11a is made of a thin plate such as stainless steel or plastic material, and is roughly box-shaped. A heat insulating member 11b is disposed on the outer periphery of the frame 11a, and the heat insulating member 11b is protected by a protective member 11c. The heat insulating case 11 is comprised by these frame 11a, heat insulating member 11b, and protective member 11c.

[0055] A metal plate 12a is closely attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com