Heat-insulating energy-saving building block utilizing industrial waste and with uniform heat path

An industrial waste slag and block technology, which is used in climate change adaptation, building materials, building components, etc., can solve the problems of reducing the thermal insulation performance of blocks, uneven heat transfer paths, uneven heating and cooling of walls, etc., to strengthen thermal insulation capabilities. , The effect of saving block raw materials and avoiding heat transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention clearer, the present invention will be described in detail below, and the described specific embodiments are only used to explain the present invention, and are not intended to limit the present invention.

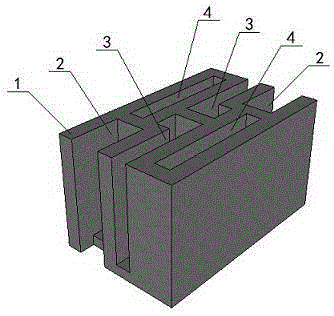

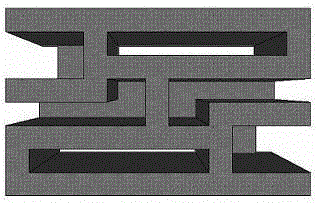

[0017] Such as figure 1 As shown, the present invention is a self-insulating building block, including a blind hole 1, a through hole 2, a blind hole 3 and a block body 4. The main materials of the matrix can be used in the following proportions: 50 parts of cement, 30 parts of fly ash, 12 parts of construction waste, 6 parts of slag, 1 part of redispersible latex powder, 1 part of water reducing agent, etc.; the water-cement ratio is 0.40. Pour the prepared materials into the pre-made molds, make the molds match each other, press and vibrate to make the blocks, and then maintain them for more than ten days.

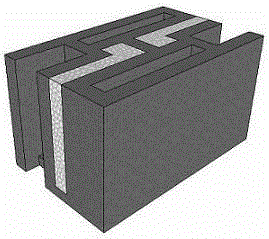

[0018] Various organic and inorganic thermal insulation materials such as polystyrene board or foam concrete can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com