Method for measuring optical part

A technology of optical parts and measurement methods, applied in the field of optical measurement, to achieve the effect of strong operability and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

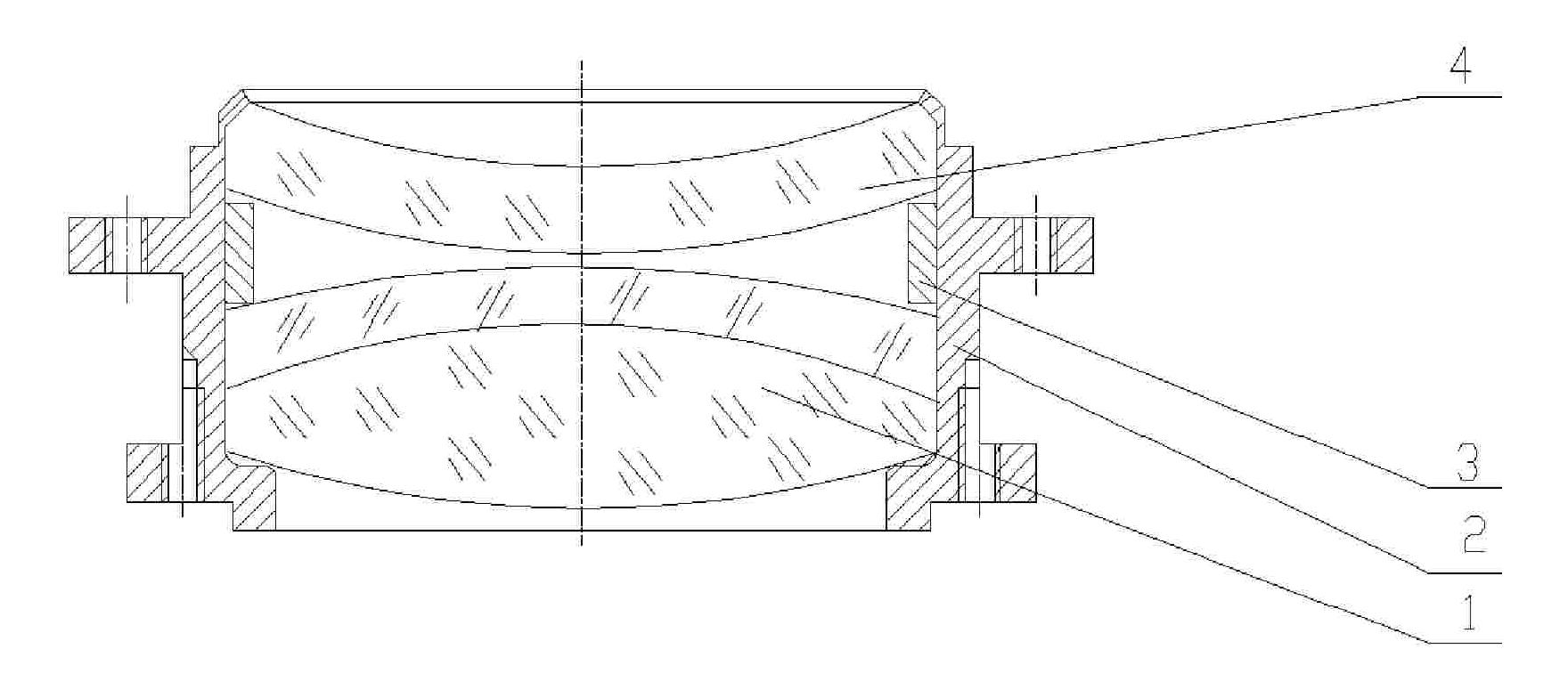

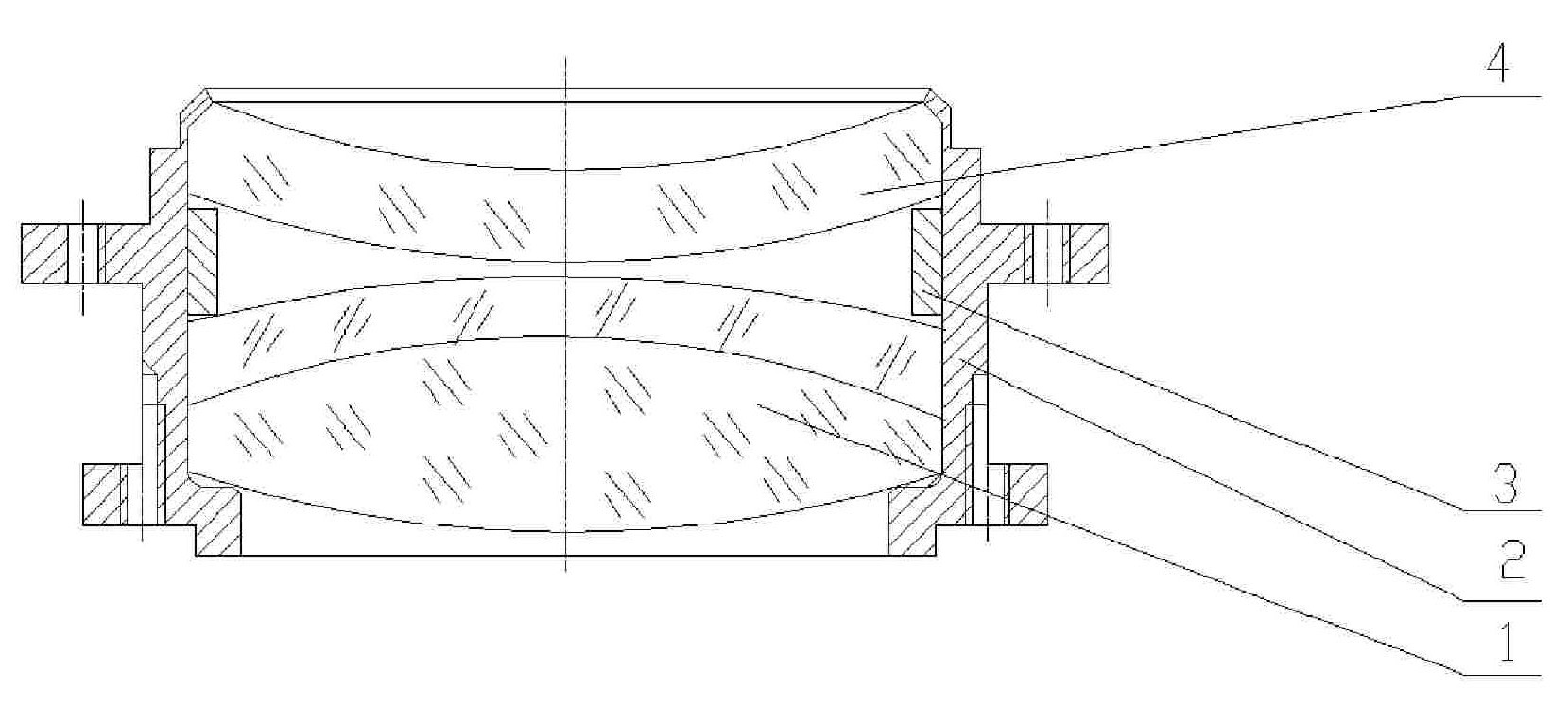

[0017] In the method for measuring optical parts provided by the present invention, the measured ambient temperature is 20°C ± 2°C. Taking the measurement of the distance between the centers of the optical part lens 4 and the cemented lens 1 as an example, the specific steps of the measuring method are as follows:

[0018] (1) Use a three-coordinate measuring machine to carry out physical measurement of the optical parts lens barrel 2, lens 4, cemented lens 1 and adjustment block 3 with the feature measurement method to obtain relevant data on the characteristics of each part thickness, length, curved surface, etc., which can also be used The method of scanning measurement is used for measurement;

[0019] (2) Carry out mathematical modeling to the above-mentioned optical parts under the three-dimensional modeling software SolidWorks software environment according to the measured part characteristic data, obtain the three-dimensional mathematical model of each part;

[0020] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com