Pneumatic tire

A technology for pneumatic tires and tires, which is applied in the direction of pneumatic tires, tire parts, tire treads/tread patterns, etc., can solve the problems of handling stability and quietness reduction, and achieve the purpose of suppressing the reduction of rigidity, improving grip, and suppressing Easy to clog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

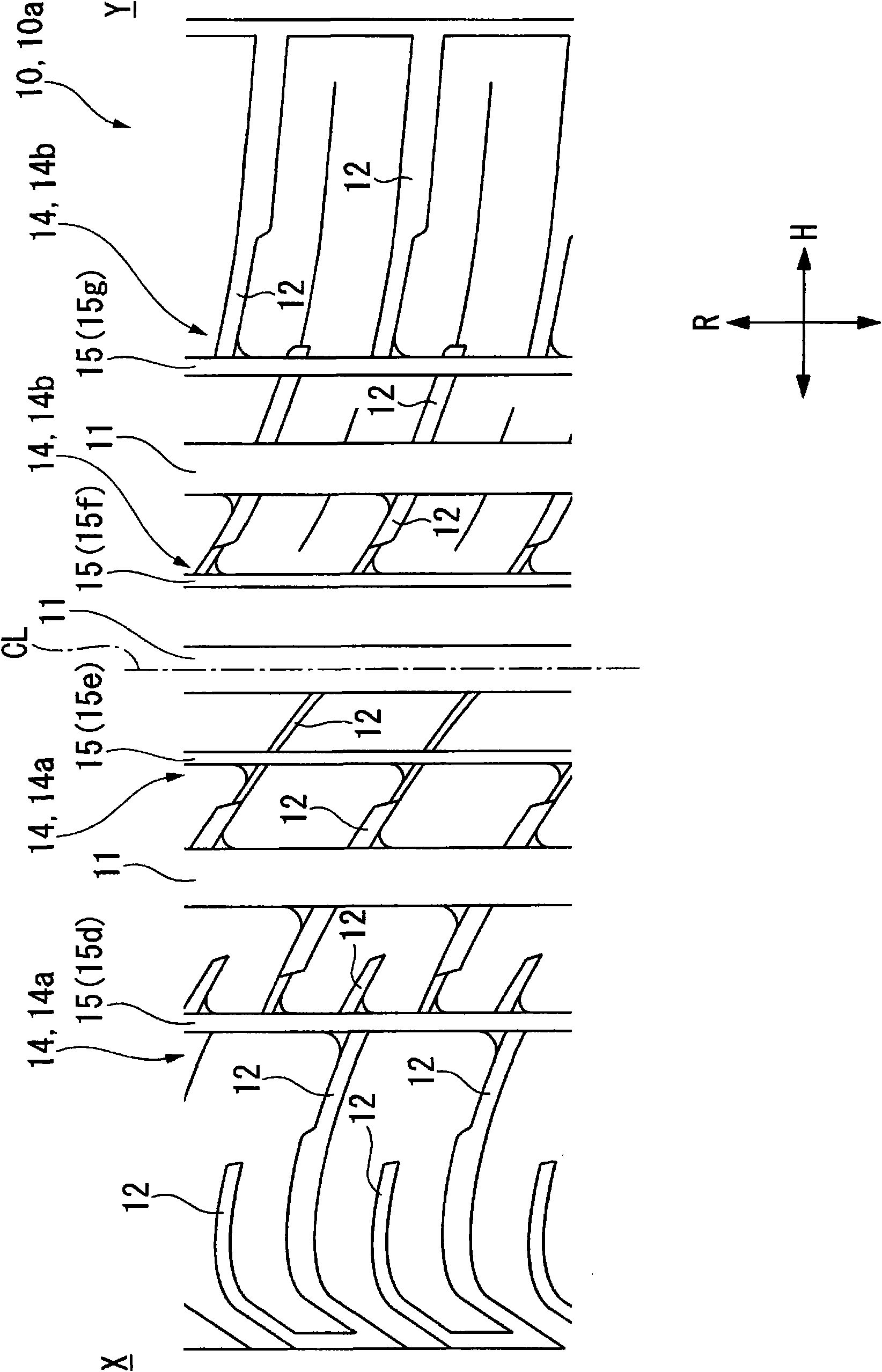

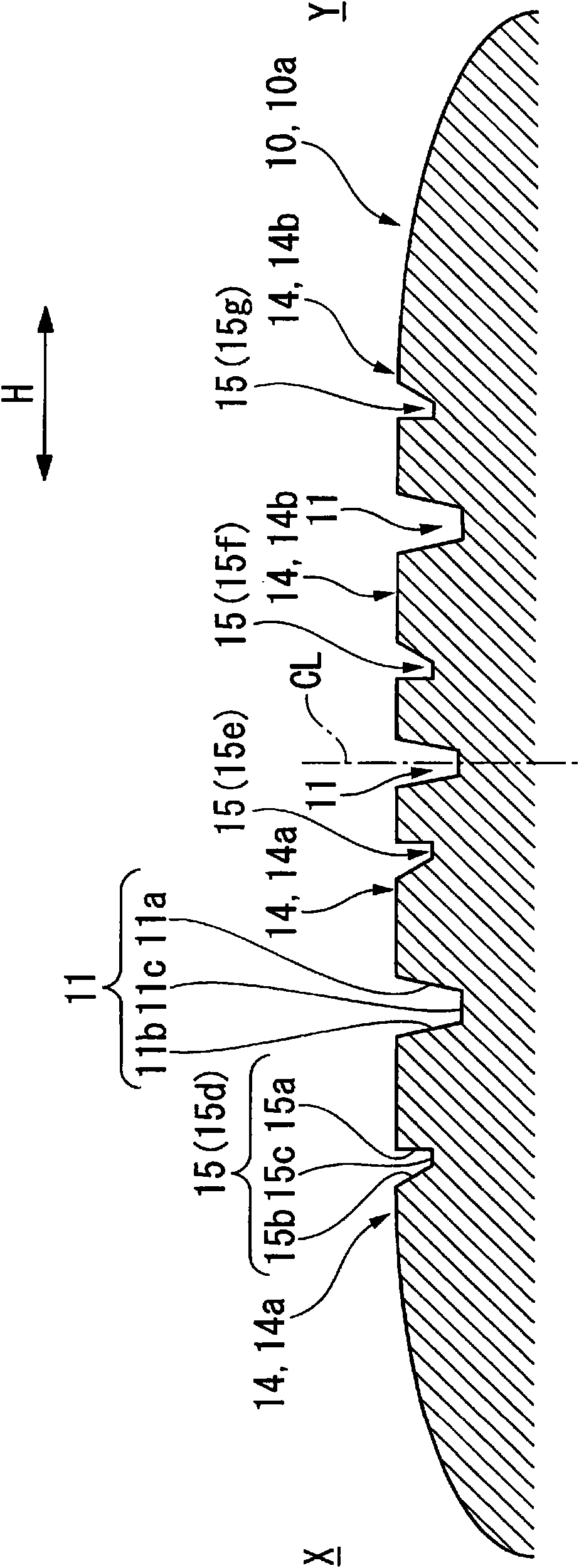

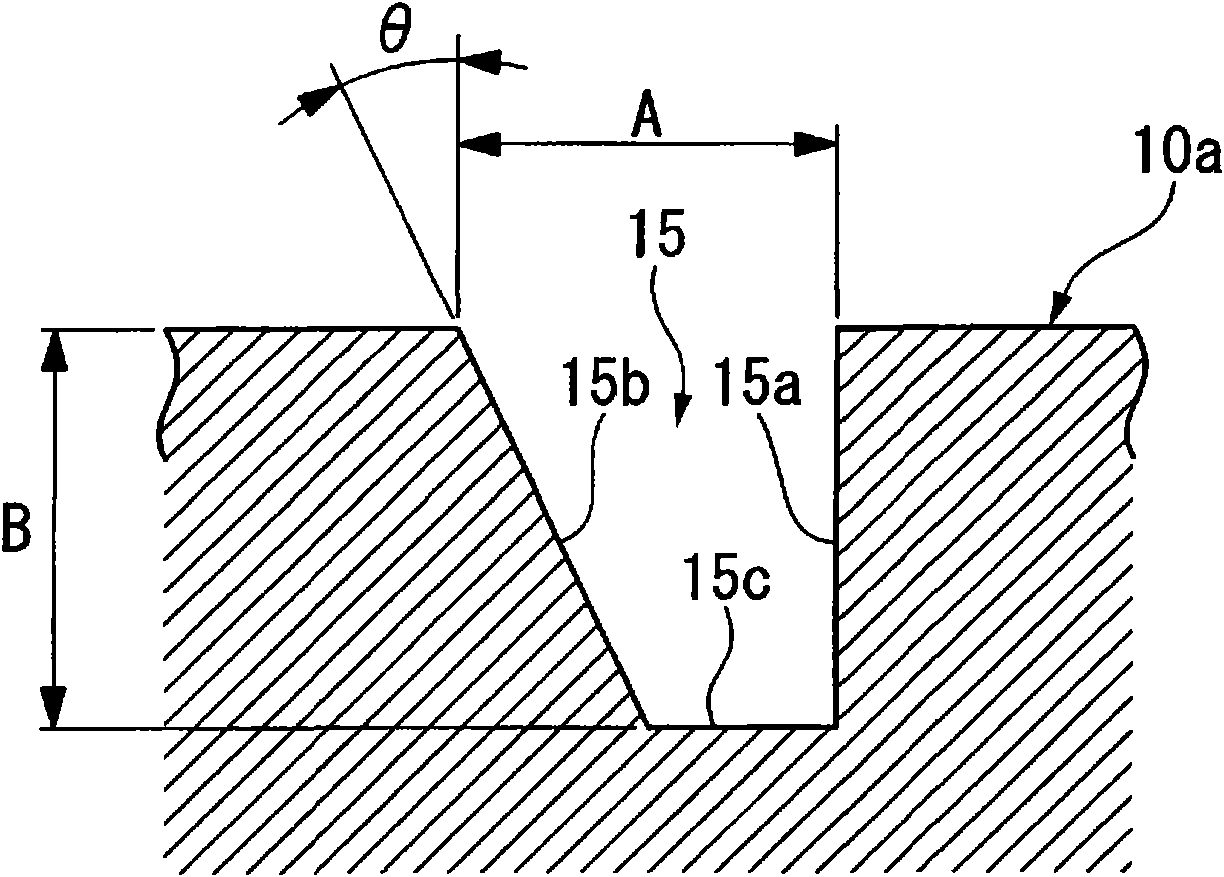

[0024] Below, refer to the attached Figure 1~3 One embodiment of the pneumatic tire of the present invention will be described. On the tread portion 10a of the pneumatic tire 10, a plurality of circumferential main grooves 11 extending in the tire circumferential direction R are formed at intervals in the tire width direction H, and a plurality of land portion rows 14 are defined by these circumferential main grooves 11. .

[0025] In the illustrated example, three circumferential main grooves 11 are formed, one of which is arranged so that its widthwise center is located on the tire equator CL, and the other two are arranged respectively from the tire equator CL to the vehicle outer side X and the vehicle inner side Y. Empty the positions at equal distances respectively. Accordingly, the plurality of land portion rows 14 are arranged at four positions separated from the tire equator portion CL on the tread portion 10a. Specifically, two of the four land portion rows 14 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com