Method for determining a functional state of a piezoelectric injector of an internal combustion engine

A piezoelectric injector, internal combustion engine technology, applied in piezoelectric device or electrostrictive device parts, fuel injection device, machine/engine, etc., can solve problems such as the influence of electrical characteristic parameters, and achieve accurate capacitance measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

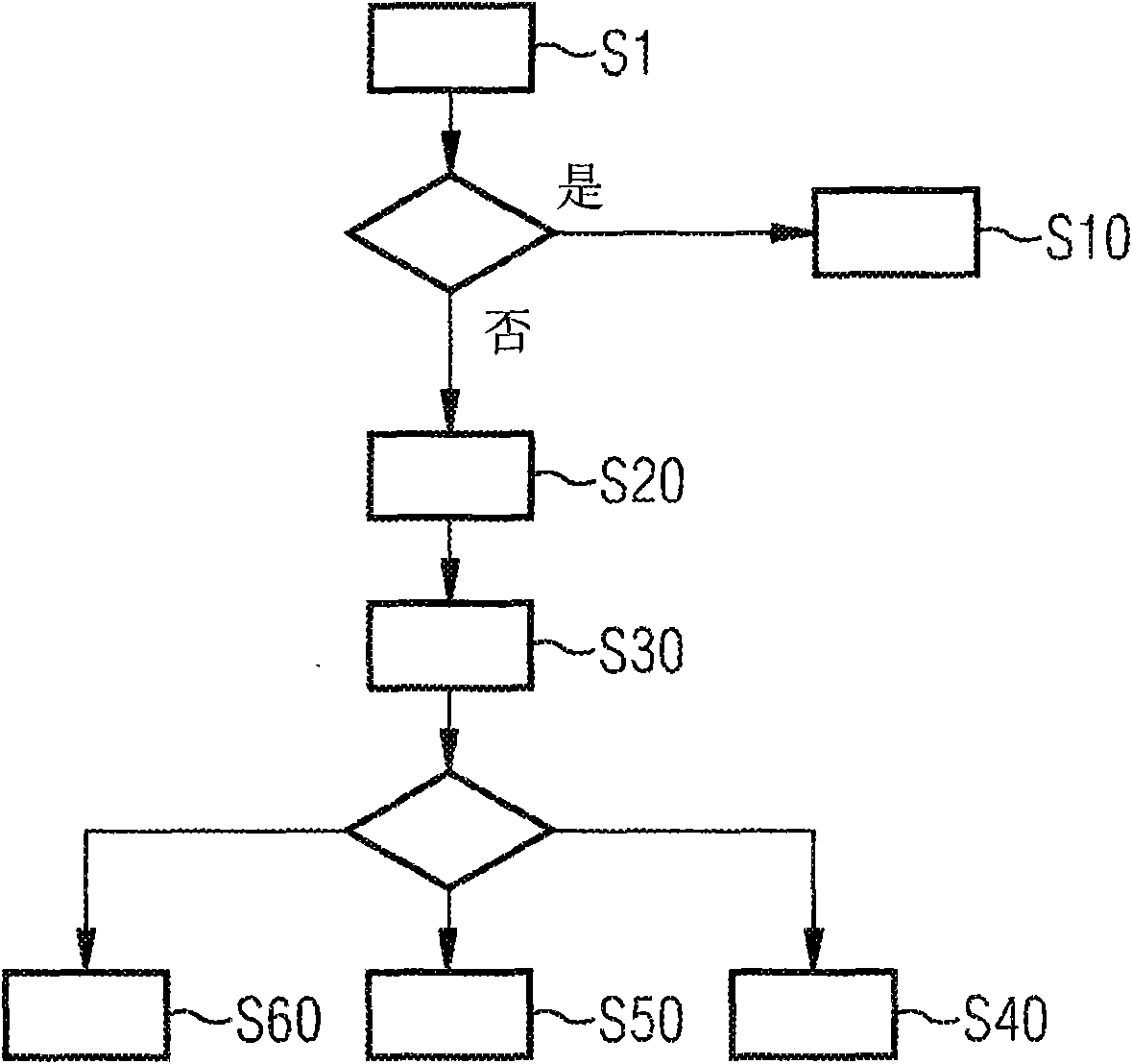

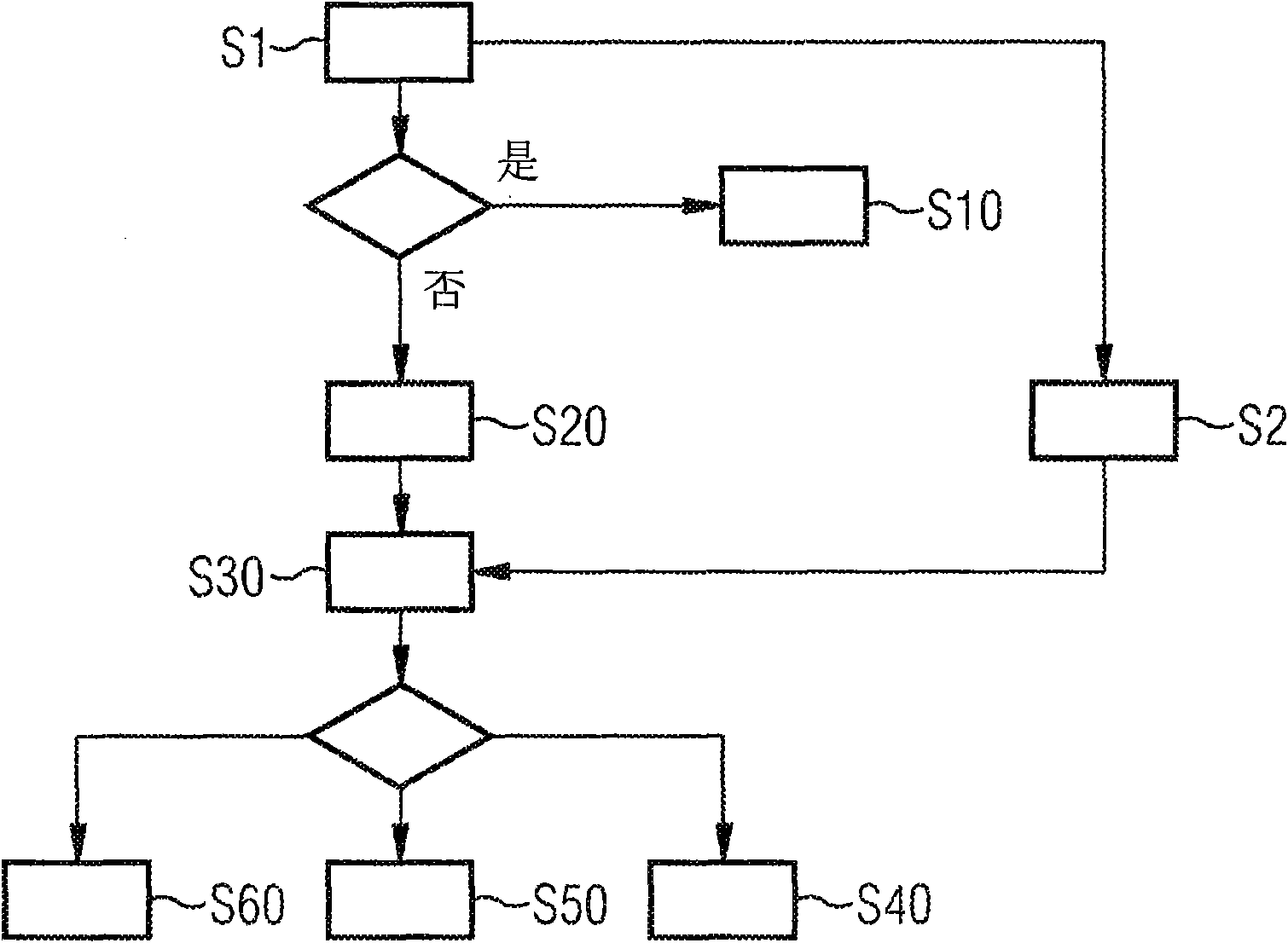

[0023] exist figure 1 A method for detecting an impending failure of a piezo injector is shown in a flow chart.

[0024] In a first step S1 it is checked whether favorable system conditions exist with respect to, for example, the fuel pressure, in order to carry out a capacitive measurement. If this is the case, a capacitance measurement is performed. If a first determined capacitance value is involved in the piezoelectric injector, this first determined capacitance value is stored in step S10 .

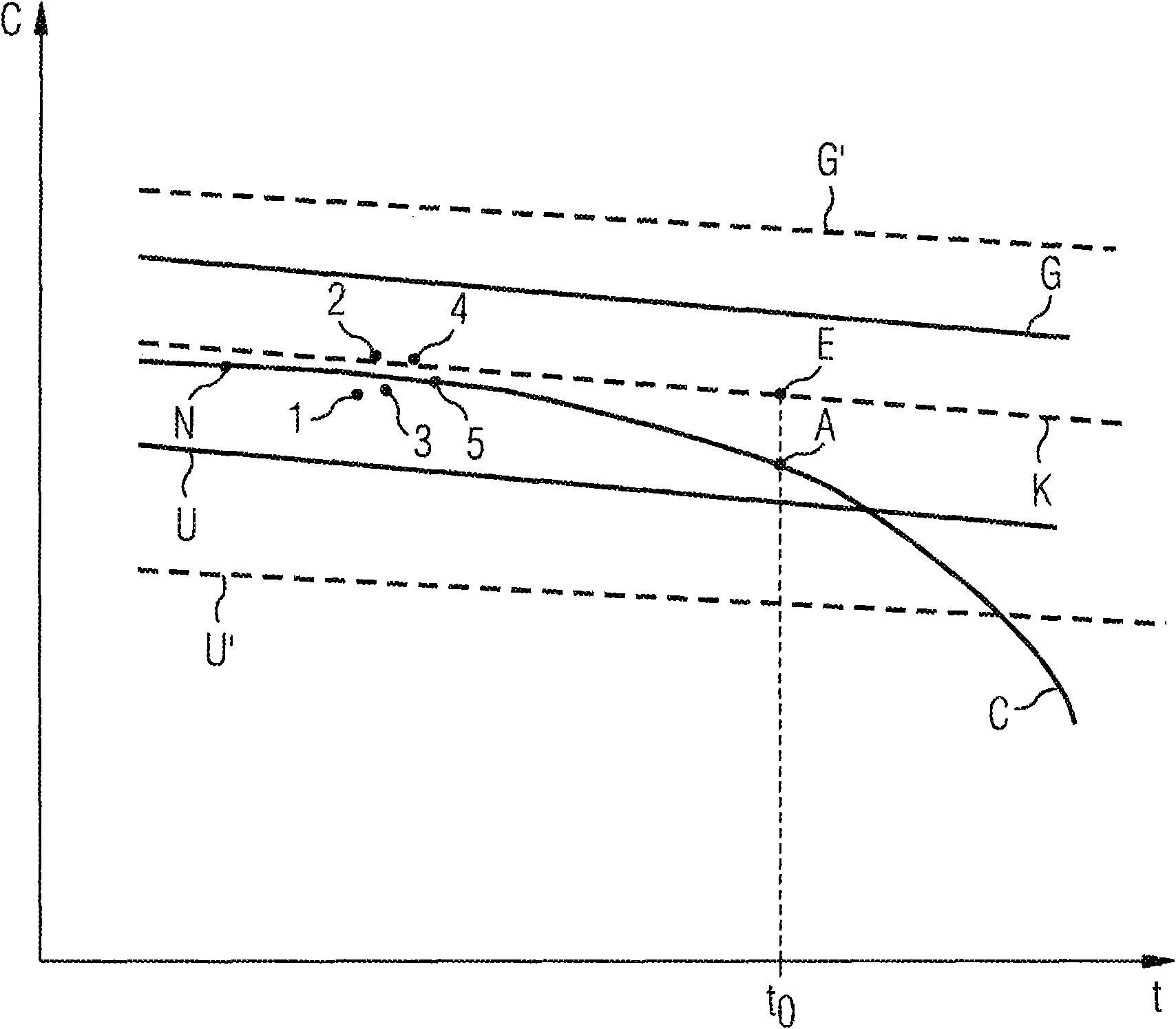

[0025] The capacitance value to be compared with the measured capacitance value is calculated in step S20. The calculation is based on a functional equation, which is determined using a mathematical approximation with the aid of the new capacitance value and at least one measured value. The calculated capacitance value is compared with the measured capacitance value in step S30. If the measured capacitance value would be outside the first tolerance range, a signal is sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com