Extrusion-type automatic paint injection paintbrush

A paint brush and extrusion technology, applied in the field of painting tools, can solve the problems of environmental pollution, large waste of paint energy, waste of paint and painting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

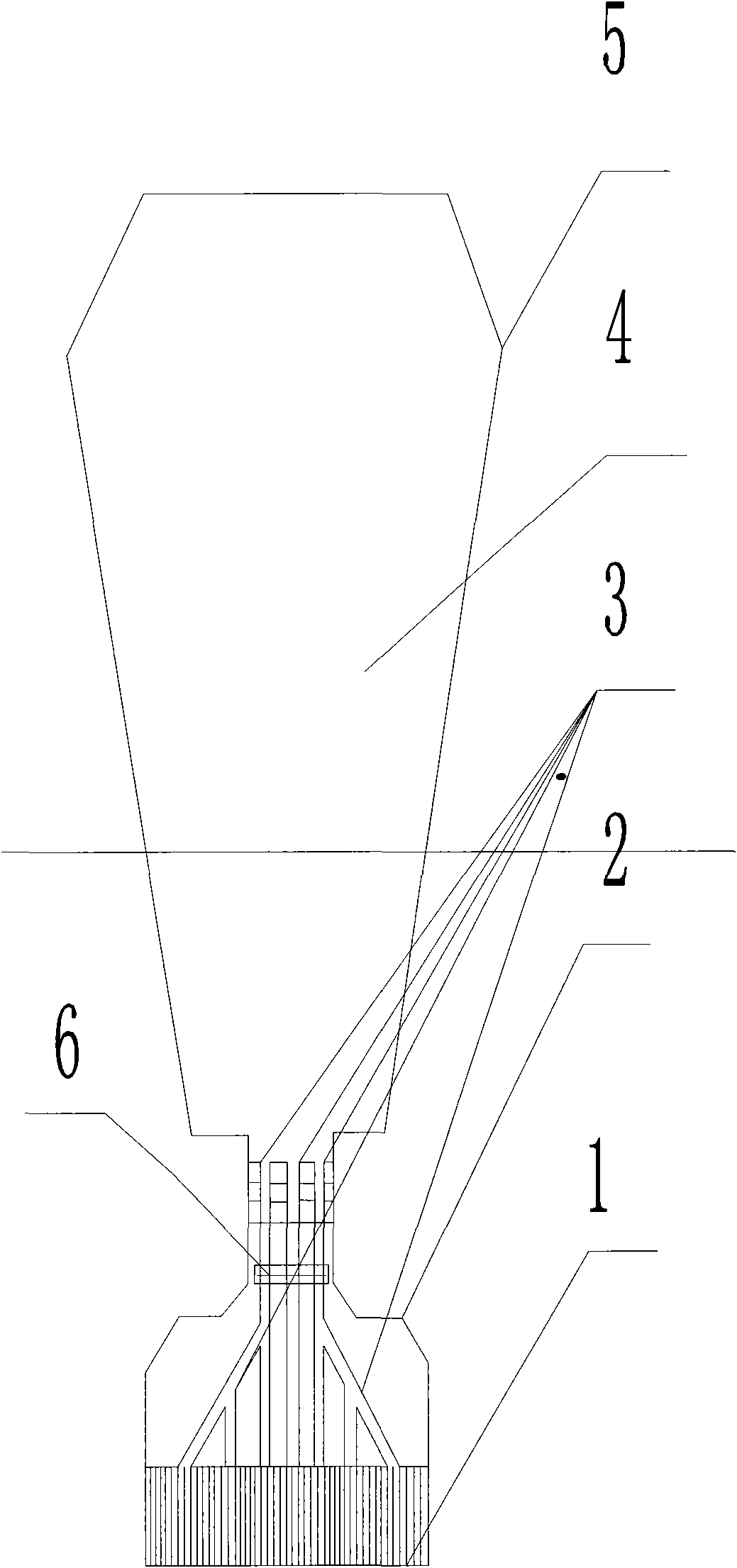

Examples

Embodiment Construction

[0008] In order to fully explain the production and use of the "squeeze-type automatic paint brush", the following instructions are given:

[0009] 1. Preparation:

[0010] 1. The xylem handle of the finished paint brush is about 5 to 6 centimeters long. The upper mouth of the wooden handle is round, and the lower part is rectangular, which is the shape of "round sky and place".

[0011] 2. Drill several small straight holes (3-7 are acceptable) at the round mouth of the wooden center of the paintbrush vertically downwards. On both sides of the cuboid at the wider part of the paintbrush wood, drill 1 oblique hole each centripetally. The holes are connected with the straight small holes on both sides (as shown in the figure), so that the small holes are connected with the bottom of the paint bristle and the paint pot, so that after the paint is squeezed, it will automatically flow from the paint pot to the bottom of the paint bristle.

[0012] assembly.

[0013] 3. It is bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com