Countercurrent extractor

A technology for countercurrent extraction and extraction liquid, applied in the field of extractors, can solve the problems of solvent leakage, low extraction rate, low processing capacity, etc., and achieve the effects of large production volume, complete extraction and obvious concentration gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

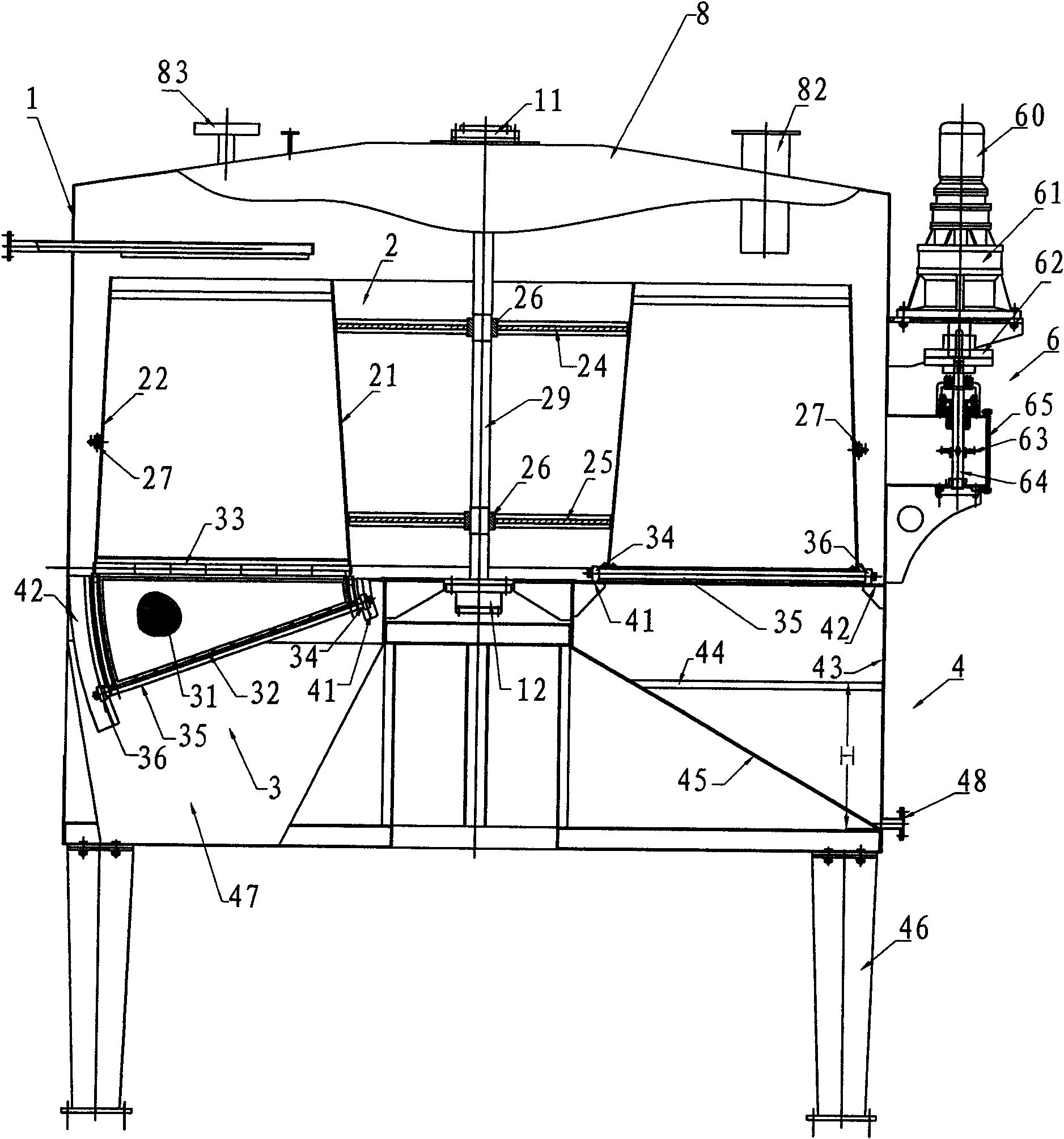

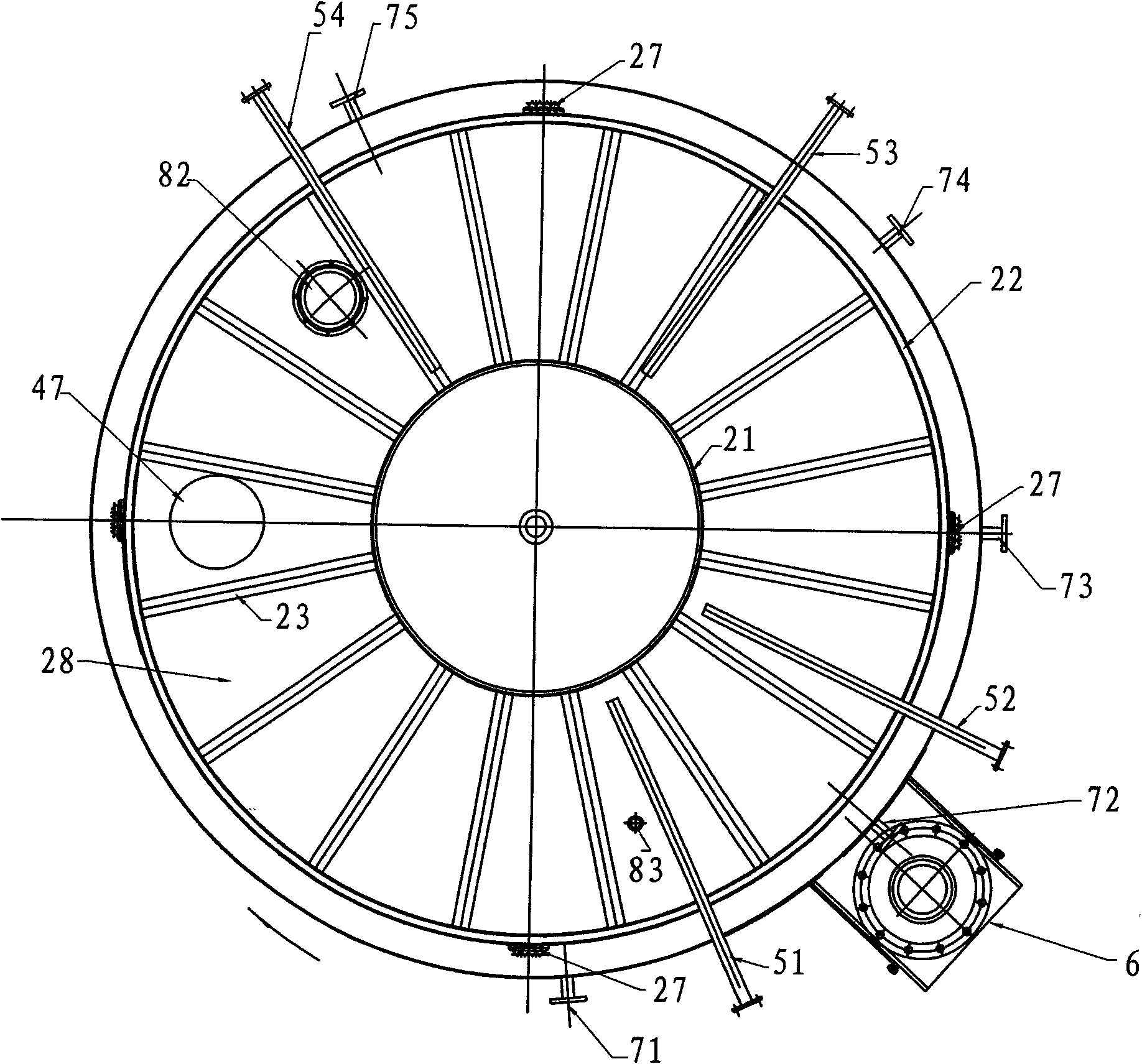

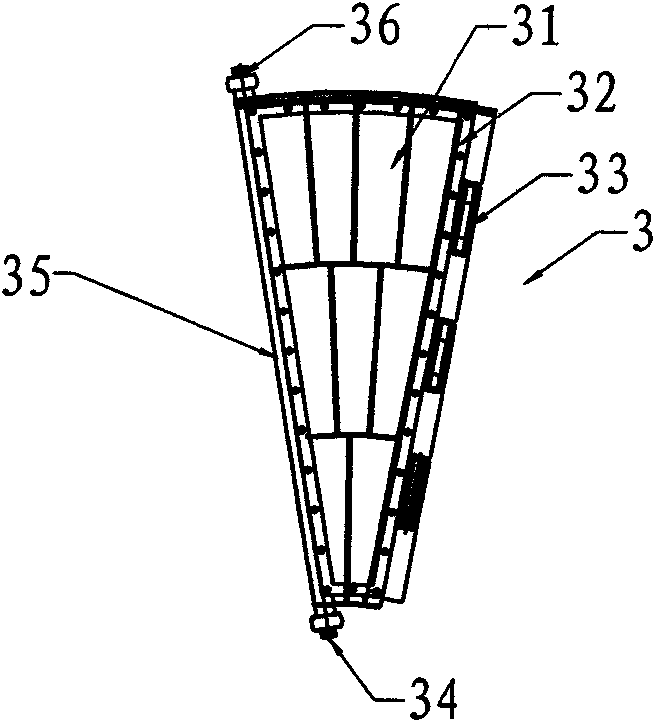

[0023] Such as figure 1 and figure 2 As shown, the countercurrent extractor in this embodiment includes a tank body 1, a base 4, a rotating body 5, a valve 3, an inner track 41 and an outer track 42 arranged on the top of the base 1, several liquid collecting buckets, and a top cover 8 And the electric drive mechanism 6, the base 4 is provided with a supporting foot 46 below.

[0024] The tank body 1 has a solvent inlet 83, an extraction liquid outlet 48, a material inlet 82 and a material outlet 47. A rotatable rotating shaft 29 is arranged longitudinally in the middle of the tank body 1, and the two ends of the rotating shaft 29 are arranged in the bearing housing 11 and the bearing housing 12.

[0025] The rotating body 2 is rotatably arranged in the tank body 1, and is composed of an inner cylinder 21 and an outer cylinder 22, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com