Copper-nickel-iron communication cabin component

A technology of through-cabin parts and copper-nickel-iron, which is applied in the field of through-cabin parts to reduce the risk of cracks and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

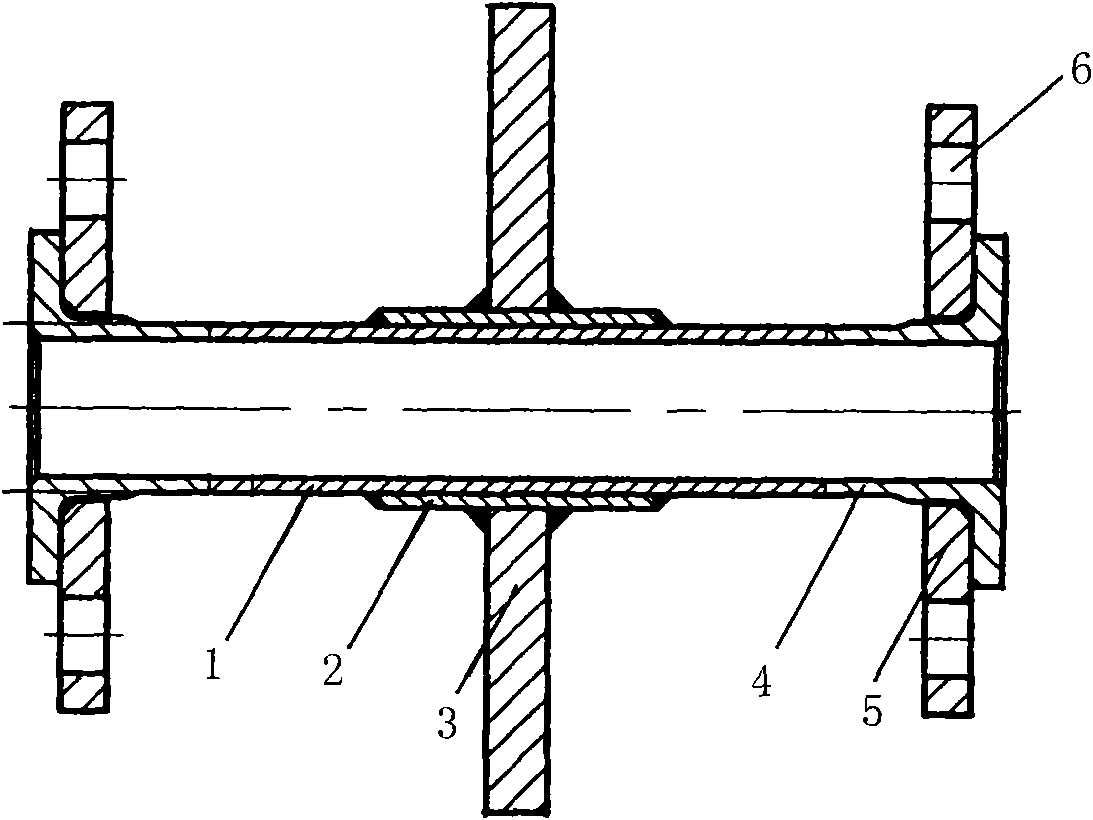

[0009] see figure 1 , copper-nickel-iron through cabin parts, including a copper-nickel-iron outer tube 2, a copper-nickel-iron inner tube 1, two outer flanges 5 and a wallboard 3, the inner diameter of the copper-nickel-iron outer tube 2 is the same as that of the copper-nickel-iron inner tube 1 The outer diameters of the copper-nickel-iron tubes are the same, 2 sets of copper-nickel-iron outer tubes are welded in the middle of the copper-nickel-iron inner tube 1, the copper-nickel-iron outer tube 2 and the copper-nickel-iron inner tube 1 pass through the wallboard 3 together and the copper-nickel-iron outer tube 2 It is welded and connected with the wallboard 3; a copper-nickel-iron inner flange 4 is arranged at both ends of the copper-nickel-iron inner pipe 1, and an outer flange 5 is welded on the inner surface of the copper-nickel-iron inner flange 4, and the outer flange Have the flange hole 6 that is connected with pipeline on the 5. The materials of the outer flange 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com