Hydraulic trash remover for bottom grid diversion dam of power station

A hydraulic and bottom rail technology, which can be used in earth movers/shovels, marine engineering, construction, etc., can solve the problems of lack of economic benefits, labor and time, waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

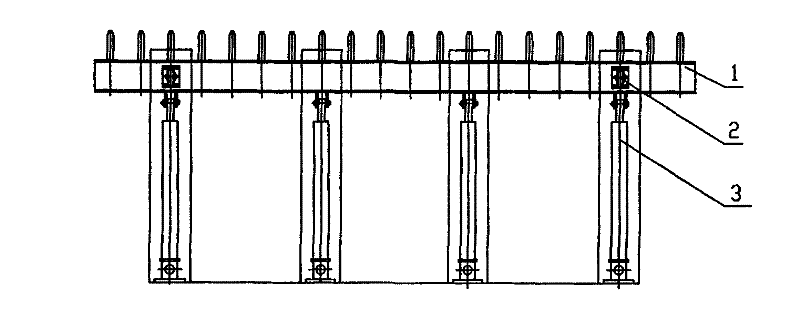

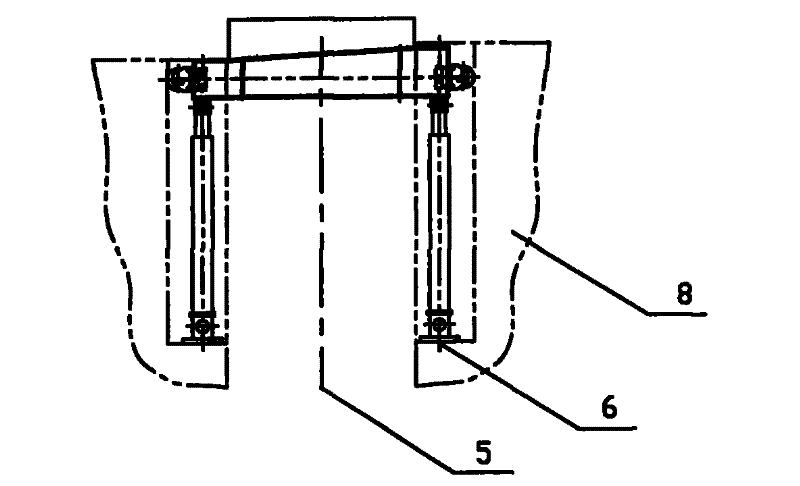

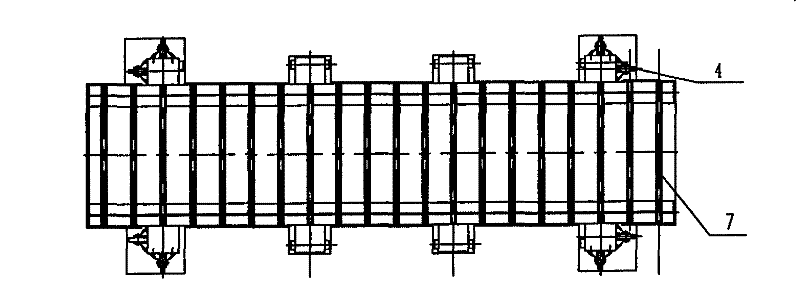

[0012] Such as figure 1 , figure 2 , image 3 As shown, a hydraulic cleaning machine for the bottom fence of a power station includes a movable grid support frame 1, a guide wheel positioning device 2, a hydraulic top 3, a lateral positioning wheel 4, a corridor 5, a hydraulic top support 6 and a fixed Bar 7, hydraulic jack 3 and lateral positioning wheel 4 are installed on the both sides of gallery 5, and hydraulic jack 3 is positioned on hydraulic jack support 6, and hydraulic jack support 6 is fixed on the concrete 8 of dam body, on the dam body Install the fixed grid 7 on the same plane as the top movable grid support frame 1, and fix the fixed grid 7 on the walls on both sides of the dam body, adjust the gap between the movable grid and the fixed grid, and install the guide wheel positioning device 2 on the movable grid The side of grid bar support frame 1 controls the left and right direction positioning of movable grid bar support frame 1, and the hydraulic system in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com