Integral installation method of top system of gas tank

An integral installation, gas tank technology, applied in gas/liquid distribution and storage, adjustable capacity gas storage tanks, mechanical equipment, etc., can solve the problems of long operation time, low work efficiency, danger, etc., to reduce operation Hazardous, simplified installation work, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

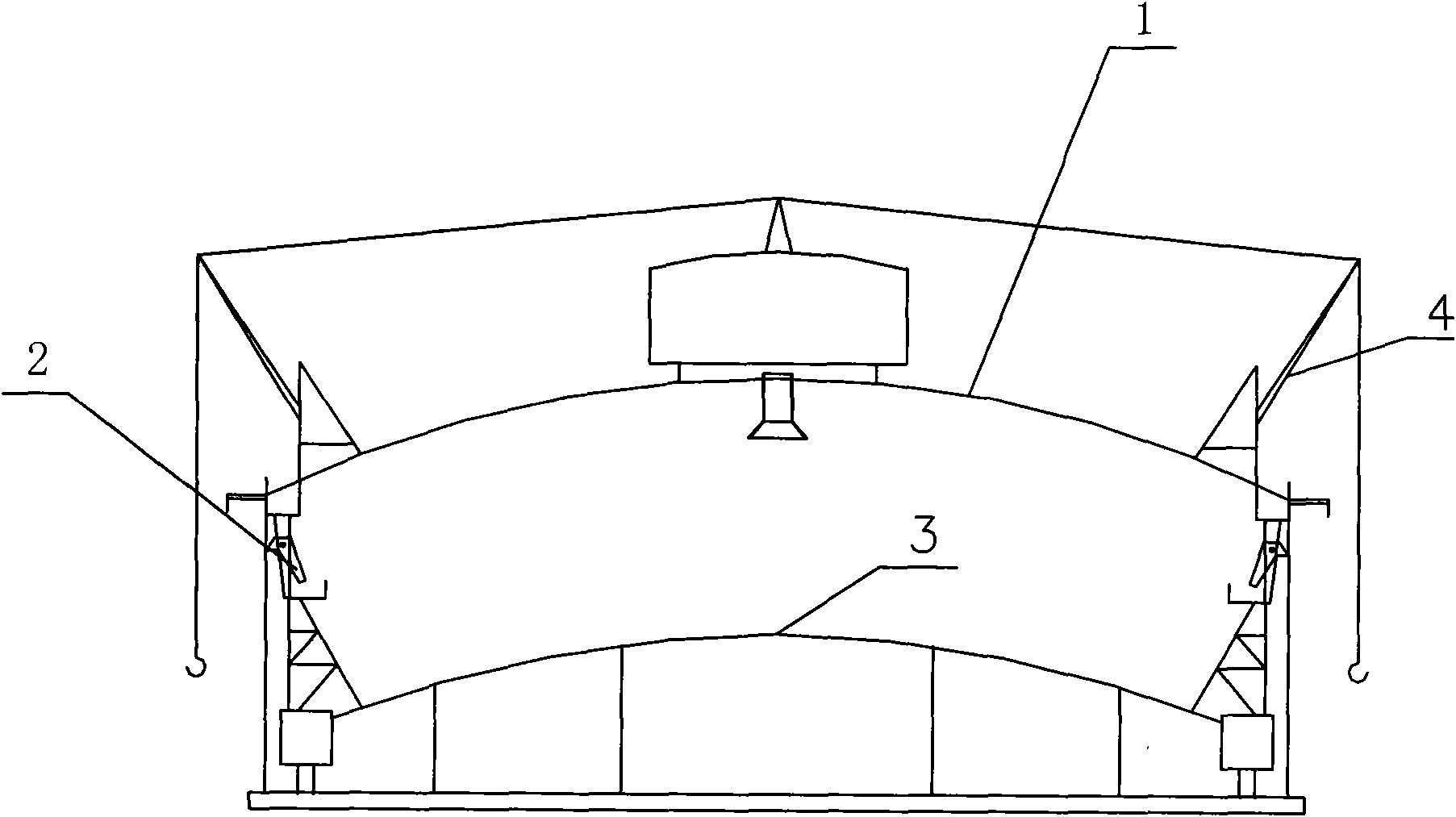

[0023] A method for overall installation of the top system of a gas cabinet, the specific steps of the method are as follows:

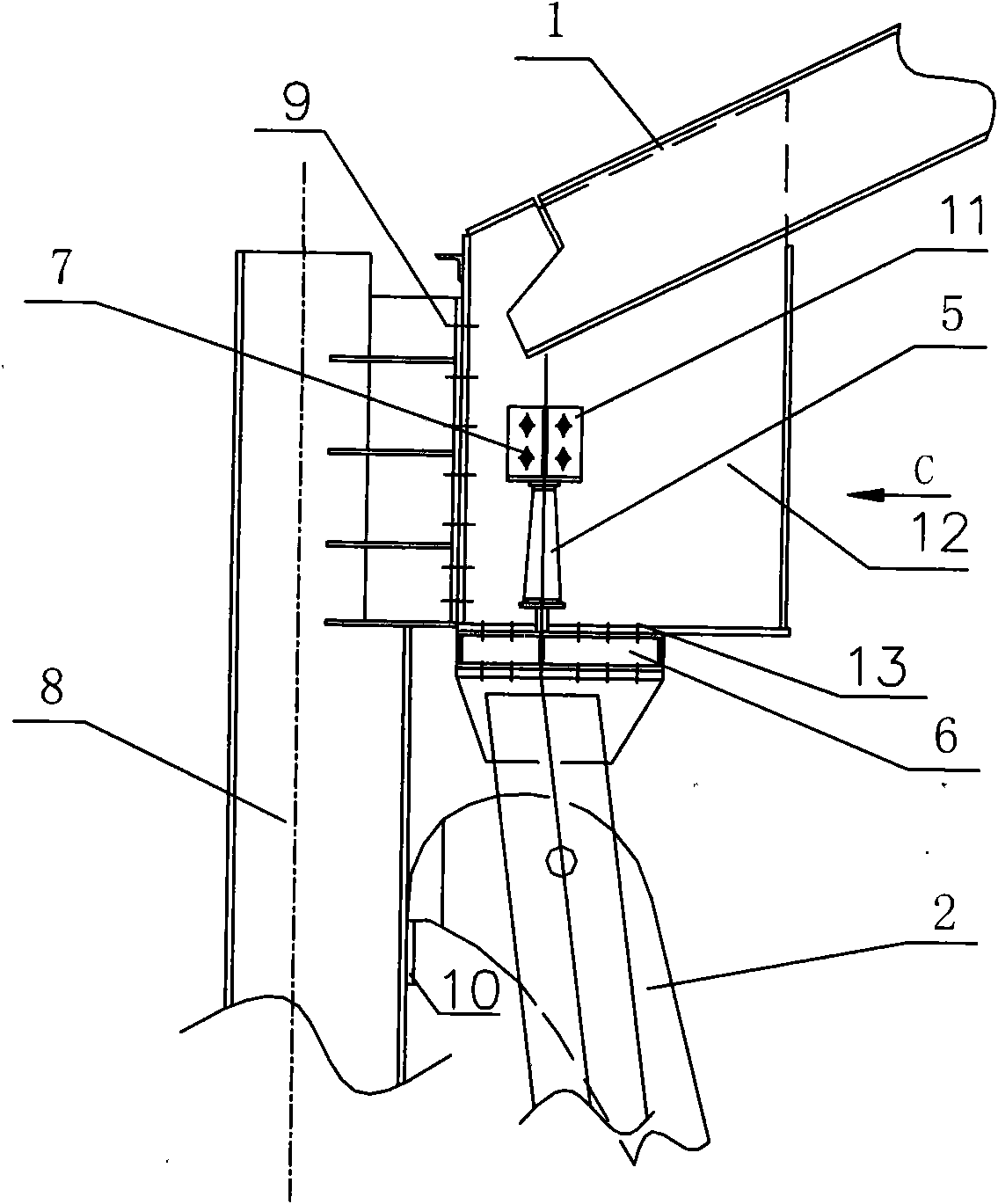

[0024] 1) Inflate the gas cabinet, float the cabinet top system 1 to a predetermined height, and hang the bird-shaped hook 2 on the temporary hanging board 10 that has been installed. Stop filling the cabinet with air. Measure corbel 11 is installed on cabinet top ring beam 12, and measure corbel 11 is connected with cabinet top ring beam 12 by bolt 7.

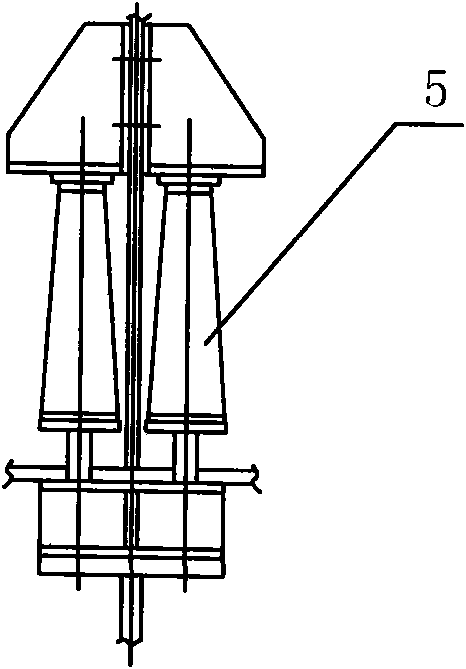

[0025] 2) Install the jack 5 on the lower part of the corbel 11 and the transition pad 6, carry out pre-lifting of the jack 5, and observe whether the stroke of the jack 5 meets the use requirements.

[0026] 3) Loosen the connecting bolts 13 between the transition pad 6 and the cabinet top ring beam 12; the transition pad and the cabinet top ring beam are connected by bolts, and this process is completed when the cabinet top structure is installed at the bottom.

[0027] 4) The jack 5 is lifted up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com