Method and apparatus for manufacturing quartz glass crucible

A quartz glass crucible and manufacturing method technology, applied in glass manufacturing equipment, glass molding, manufacturing tools and other directions, can solve problems such as collapse, and achieve the effects of reducing internal circulation flow, suppressing excessive overheating, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

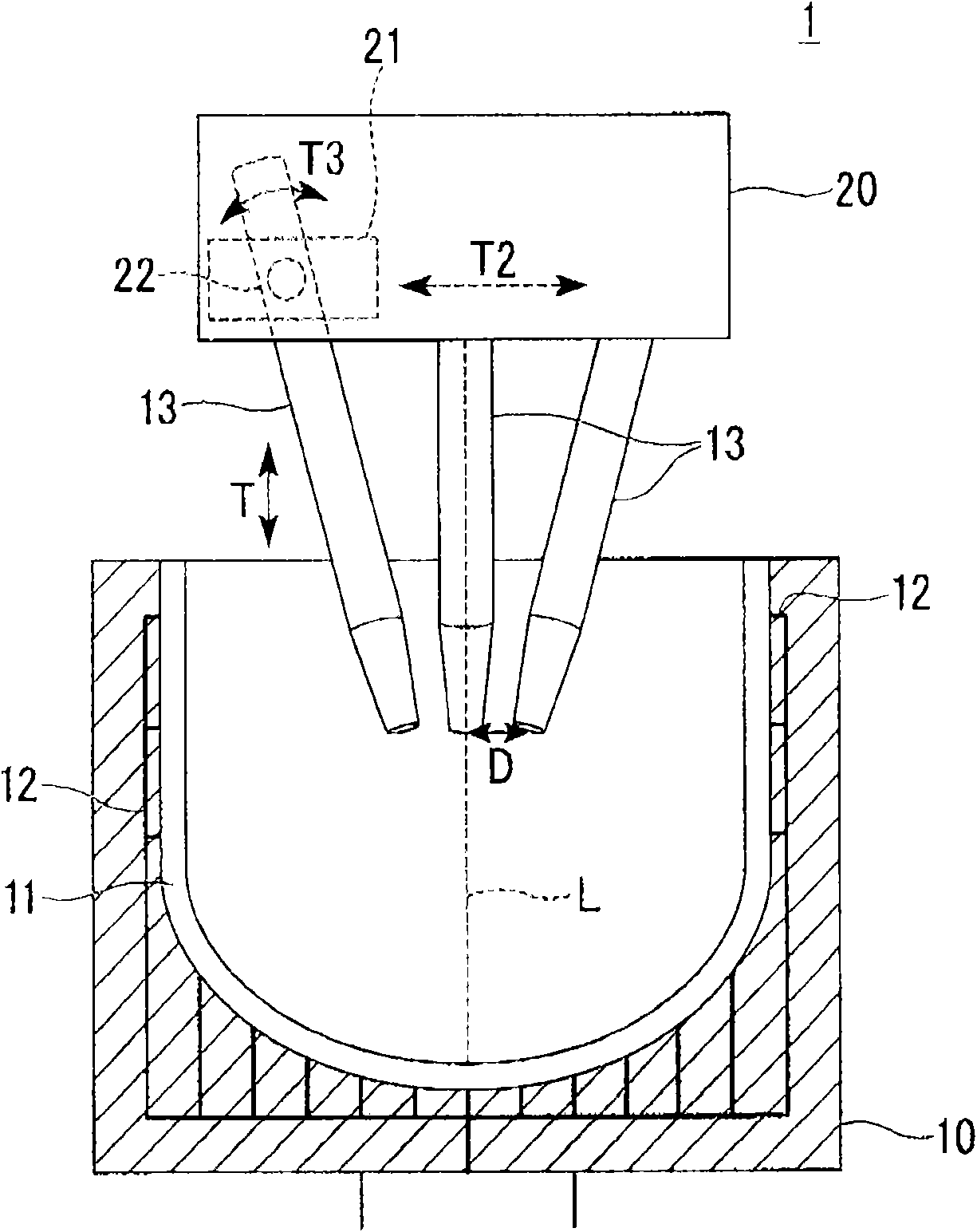

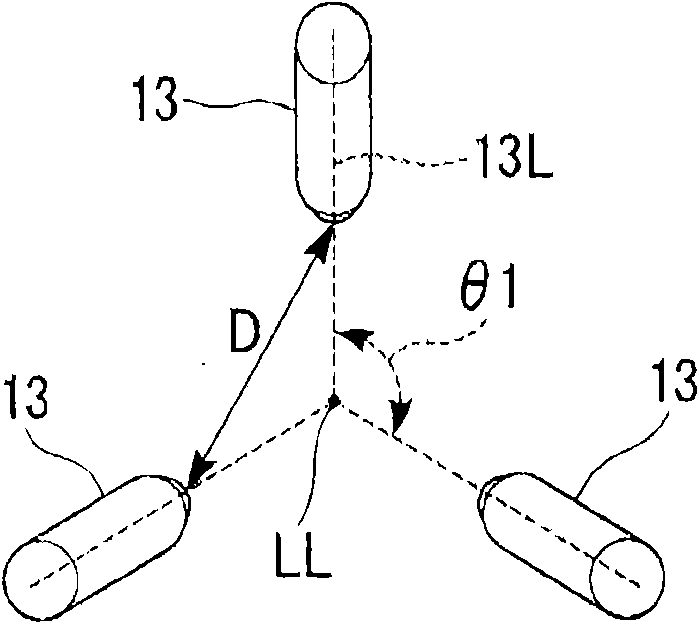

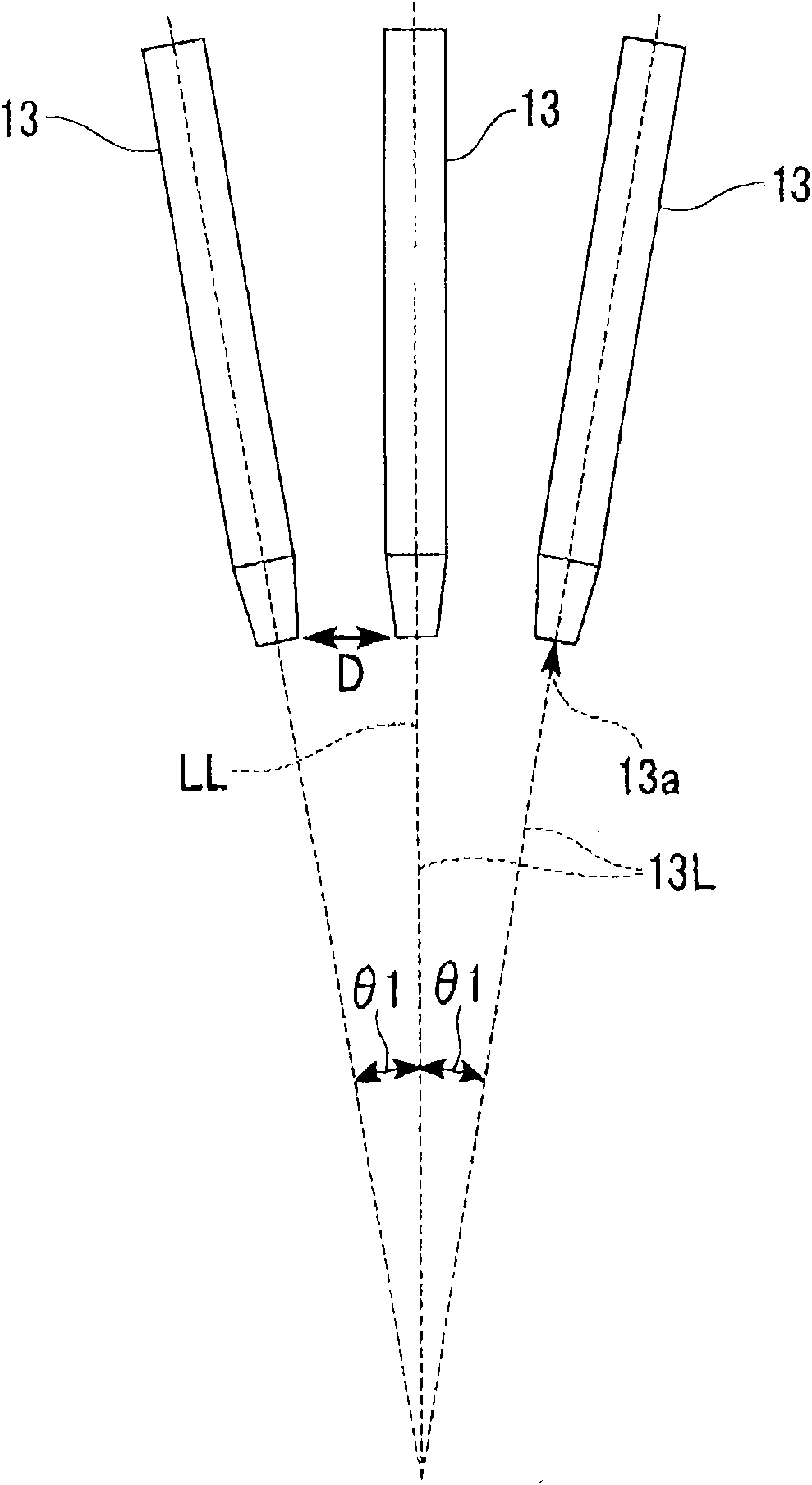

Method used

Image

Examples

Embodiment 1 to 6

[0082] Using the number of electrodes shown in Table 1, they were arranged asymmetrically with respect to the shaft rotation center line, and the quartz powder deposited on the inner surface of the mold was arc-melted and vitrified. Table 1 shows the melting temperatures and temperature differences of the crucible straight body, curved portion, and bottom during arc melting. In addition, regarding the quartz glass crucible manufactured, the layer thickness ratio of the straight body part and the transparent layer at the bottom relative to the transparent layer of the curved part is shown in Table 1 (the layer thickness ratio when the layer thickness of the transparent layer of the curved part is 100 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com