Cavity shallow foundation and construction method

A technology of shallow foundation and cavity, which is applied in the field of cavity shallow foundation and construction, can solve the problems of uneconomical, high cost, thick raft, etc., and achieve the effects of saving cost, reducing the amount of concrete, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

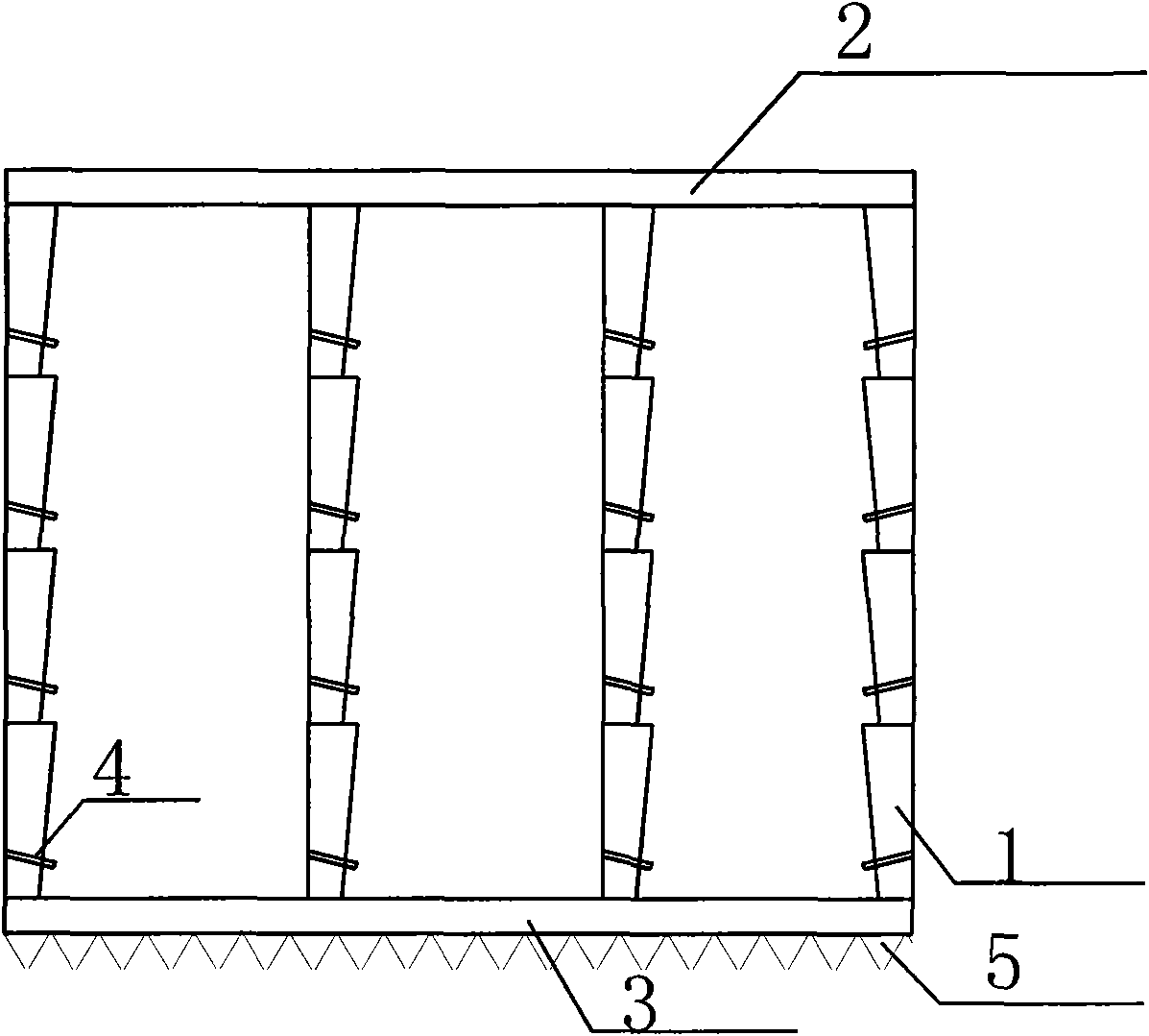

[0025] figure 1 It is a schematic diagram of a cavity shallow foundation, which includes a column 1 , a top plate 2 , a bottom plate 3 , and a drainage tube 4 .

[0026] Construction steps of the present invention include:

[0027] (1) Dig column 1 part soil.

[0028] The setting of the foundation column 1 corresponds to the span of the superstructure, and the spacing is 4.5m. Divide the foundation into three sections of column 1 according to the depth, and the height of each section of column 1 is 0.8.

[0029] (2) support pillar 1 formwork.

[0030] The thickness of the lower port of the column 1 is 80mm, and the thickness of the upper port is 150mm. The lap joint adopts a tongue-and-groove type, so that the upper and lower columns 1 are tightly lapped, and the inner wall is slightly inclined inward with a slope rate of 7%, which is convenient for formwork support. After each section of column 1 is dug down, the position of column 1 should be checked and corrected by usi...

Embodiment 2

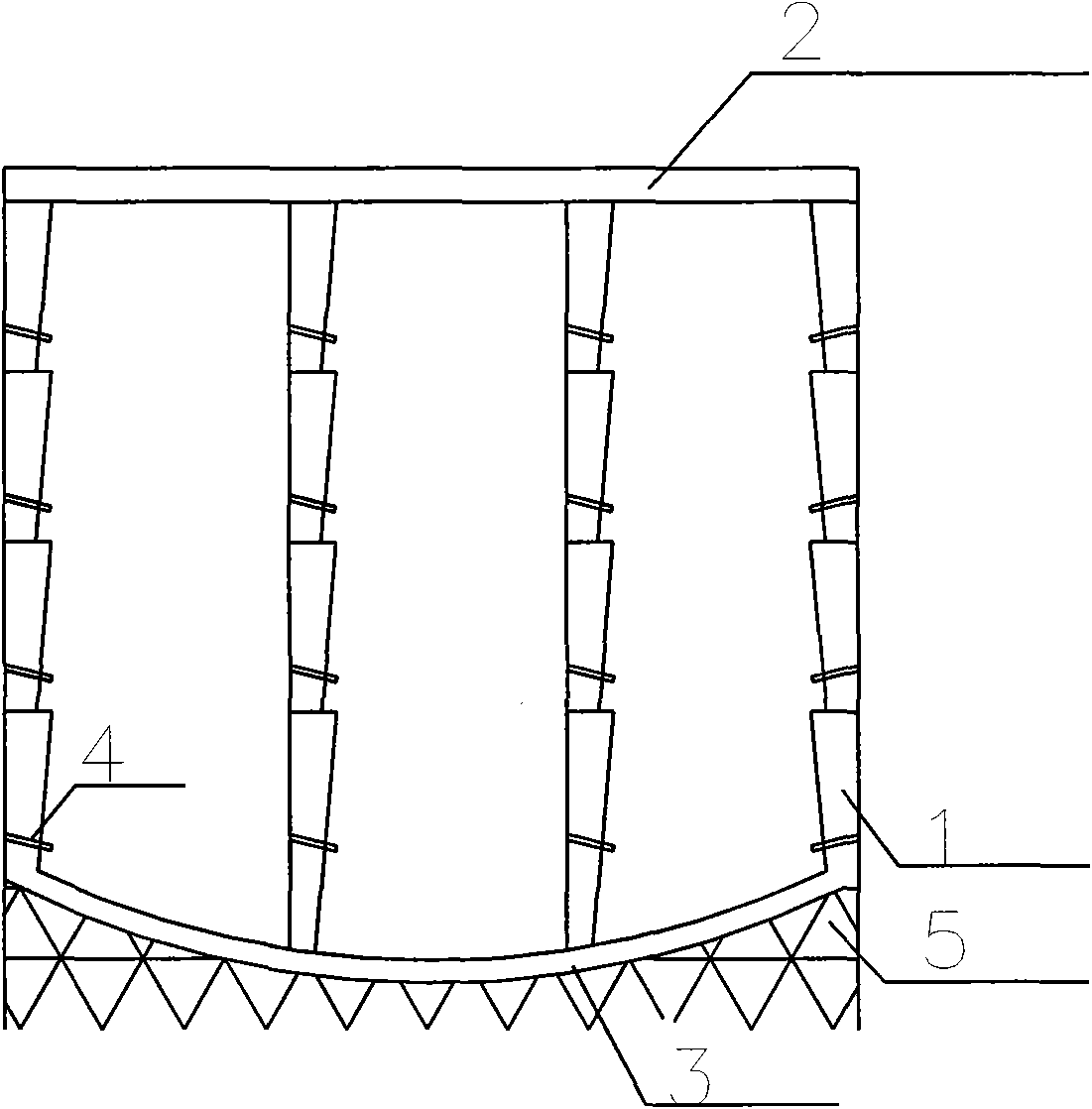

[0043] figure 2 It is a schematic diagram of cavity shallow foundation 2, which includes a column 1, a top plate 2, a bottom plate 3, and a drainage tube 4.

[0044] Construction steps of the present invention include:

[0045] (1) Dig column 1 part soil.

[0046] The setting of the foundation column 1 corresponds to the span of the superstructure, and the spacing is 4.5m. Divide the foundation into three sections of column 1 according to the depth, and the height of each section of column 1 is 0.8.

[0047] (2) support pillar 1 formwork.

[0048] The thickness of the lower port of the column 1 is 80mm, and the thickness of the upper port is 150mm. The lap joint adopts a tongue-and-groove type, so that the upper and lower columns 1 are tightly lapped, and the inner wall is slightly inclined inward with a slope rate of 7%, which is convenient for formwork support. After each section of column 1 is dug down, the position of column 1 should be checked and corrected by using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com