Rotary valve

A rotary valve and rotor technology, applied in the field of rotary valves, can solve the problems of large switching resistance, increasing the number and complexity of the inlet pipes, and increasing the complexity of the inlet pipes, so as to reduce the complexity and increase the switching frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

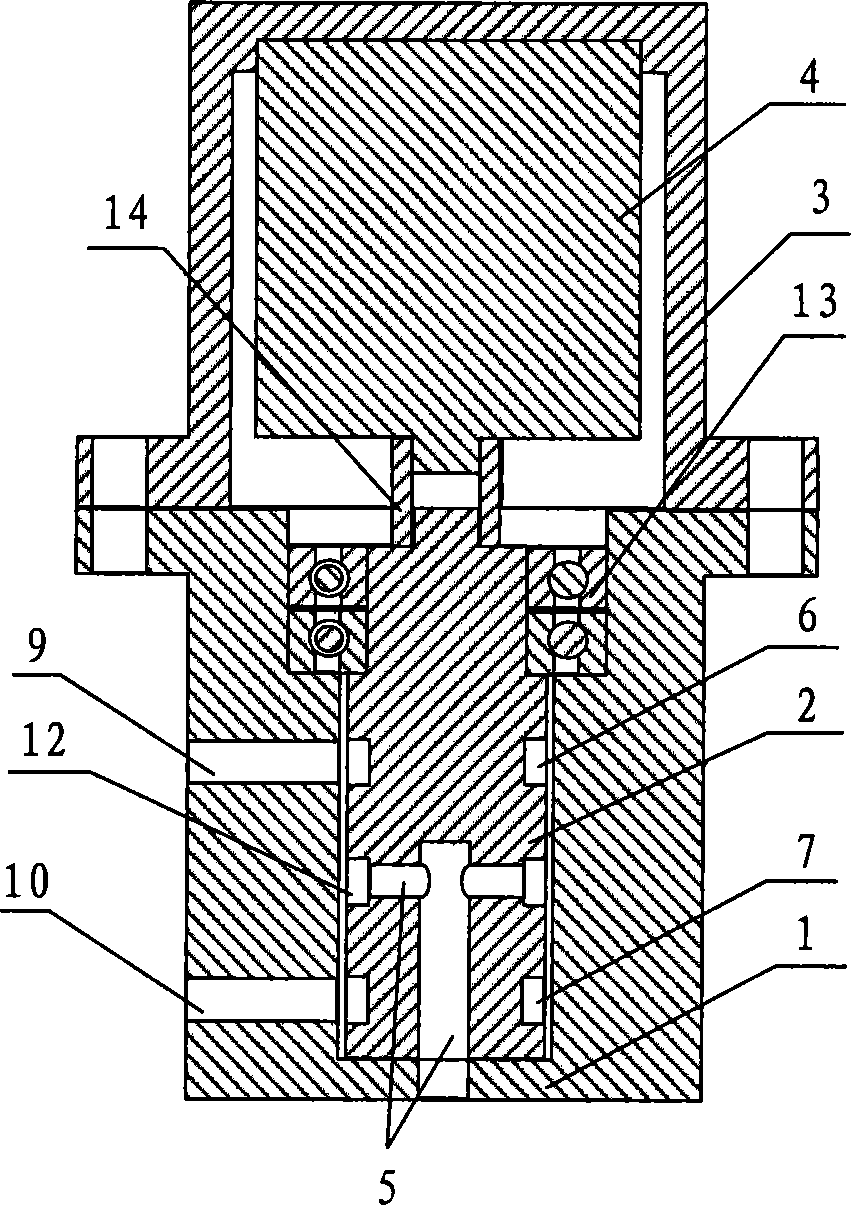

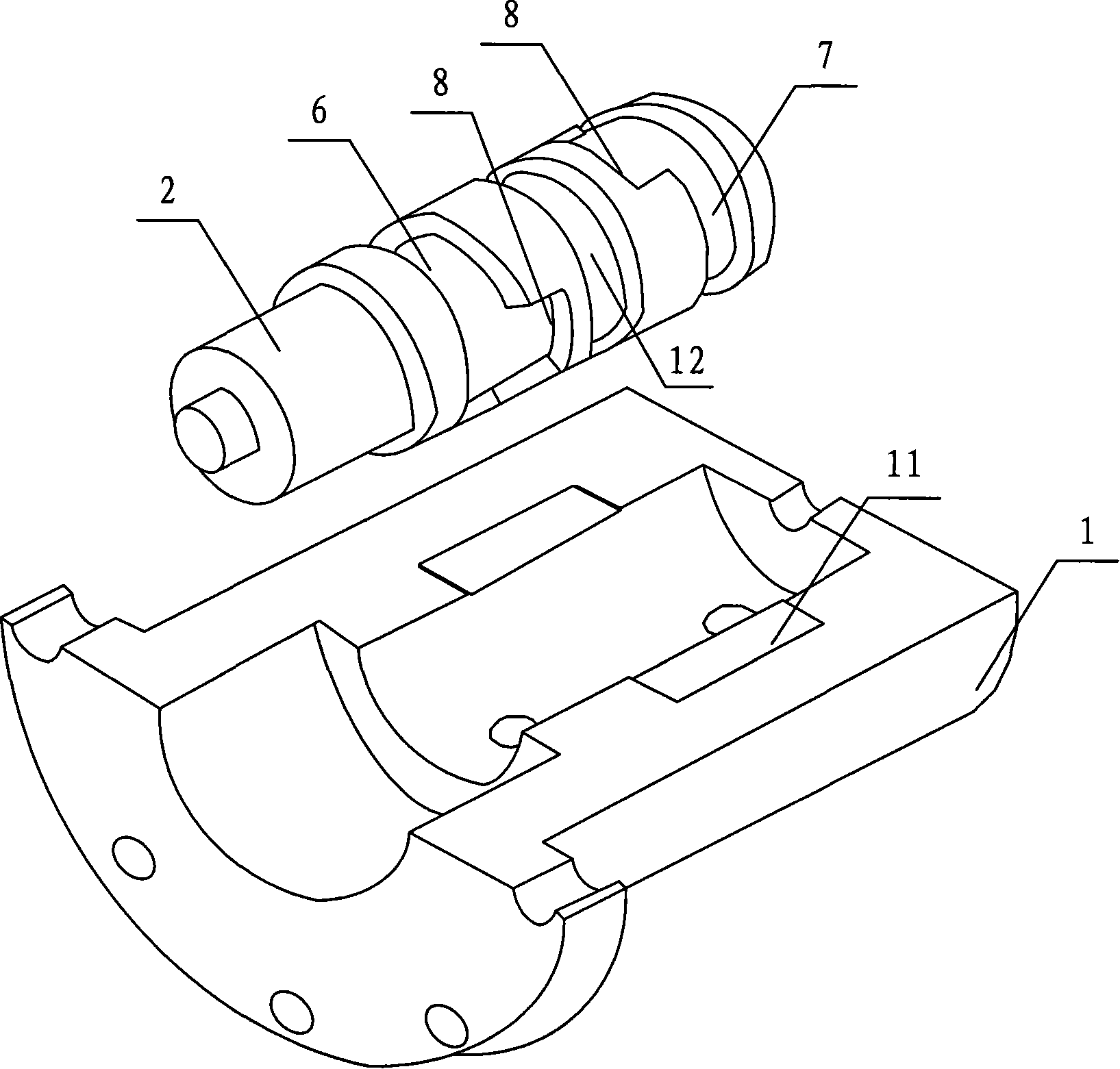

Method used

Image

Examples

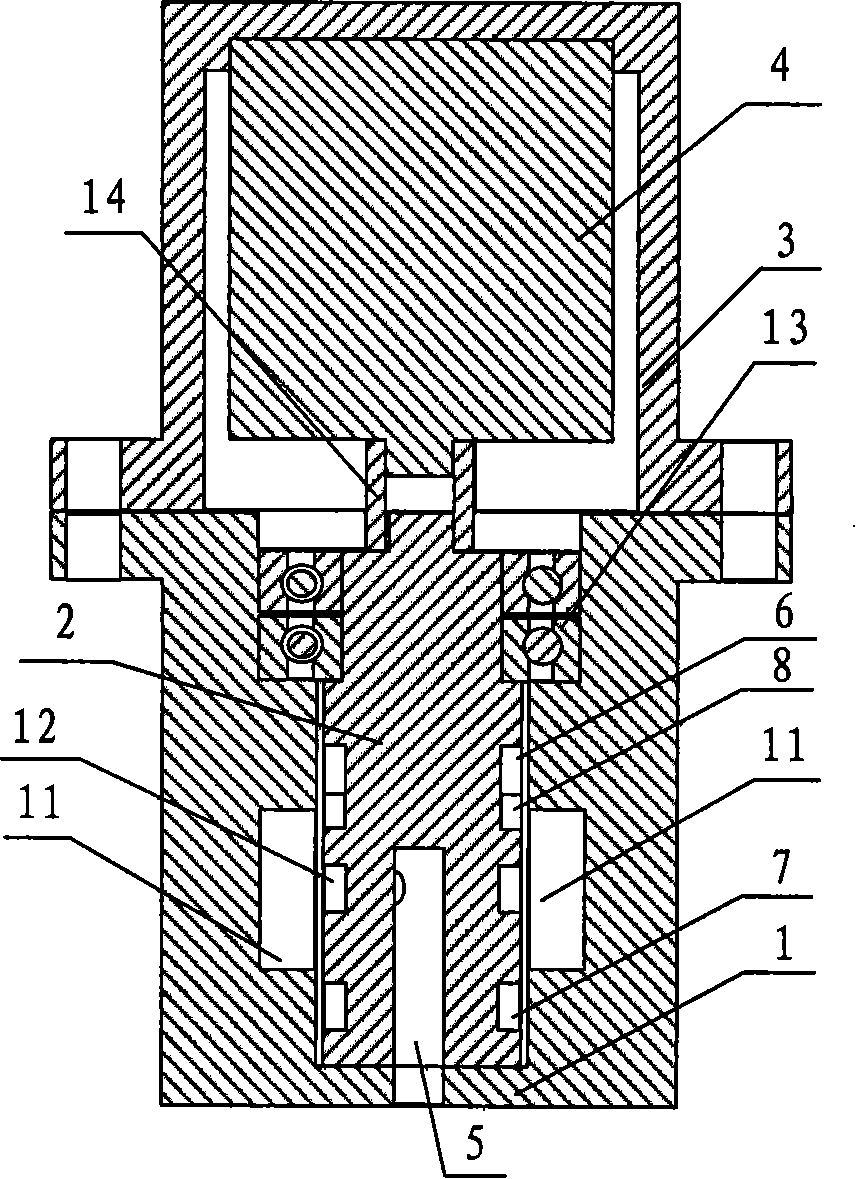

Embodiment 2

[0033] The difference between the second embodiment and the first embodiment is that the driving mechanism adopts an air motor instead of an electric motor. The air motor high-pressure inlet 16 and the air motor low-pressure outlet 17 are arranged on the sealing cover 3, the gas flows in from the air motor high-pressure inlet 16, flows through the air motor 14 to make the air motor 14 rotate, thereby driving the rotor 2 to rotate, and then flows from the air motor to the air motor at a low pressure. Exit 17 flows out. The high-pressure inlet 16 of the air motor is connected to the same high-pressure source as the high-pressure inlet 9, and the low-pressure outlet 17 of the air motor is connected to the same low-pressure source as the low-pressure inlet 10. The flow valve 18 is used to control the flow of air flowing into the air motor 14 , thereby adjusting the speed of the air motor 14 , and further controlling the switching frequency of the rotor 2 . Figure 8 for Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com