Automatic testing system of temperature compensating crystal oscillator

An automatic test system, crystal oscillator technology, applied in electronic circuit testing, instruments, measuring electricity, etc., can solve problems such as low test efficiency, unsatisfactory accuracy, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

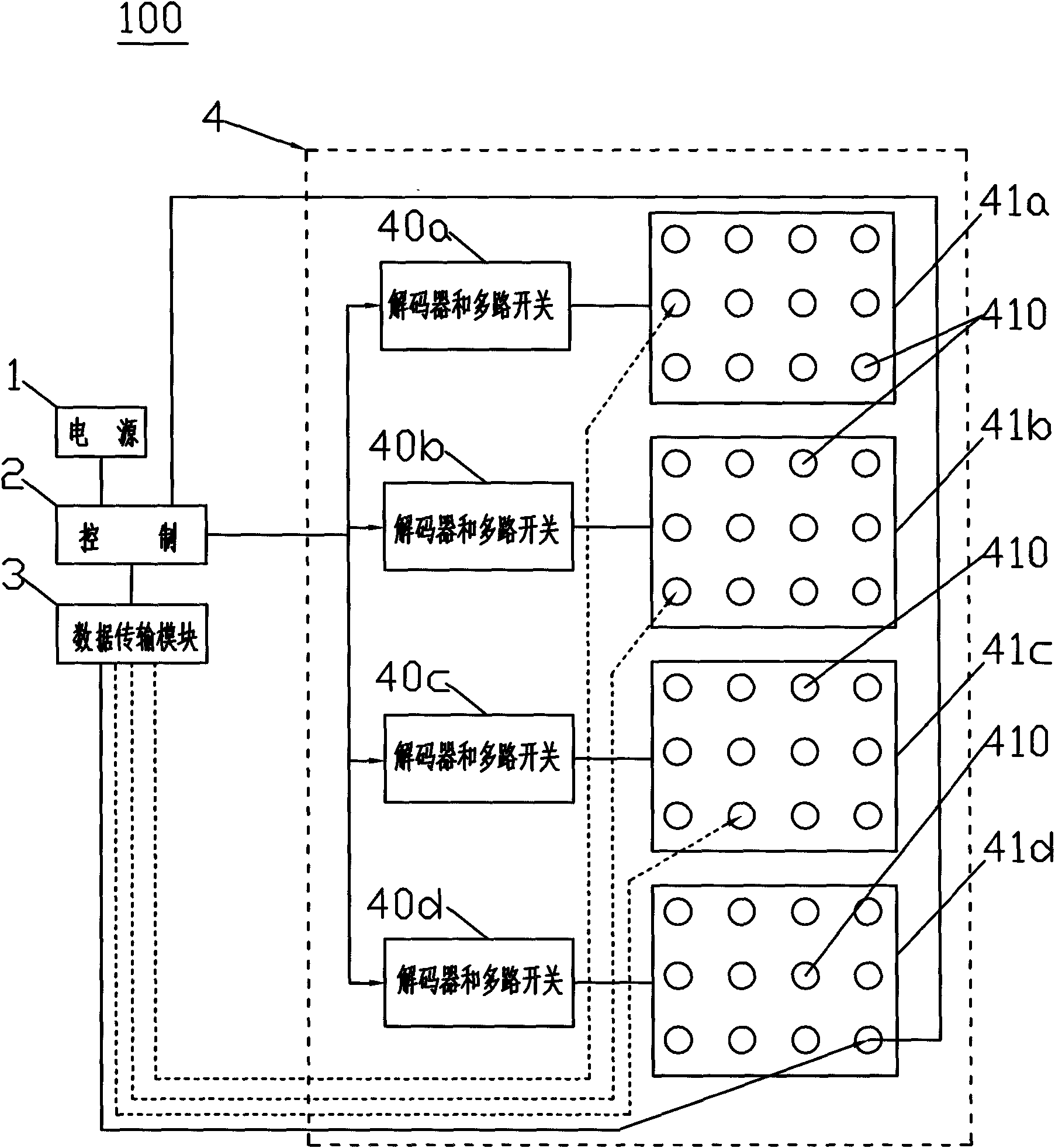

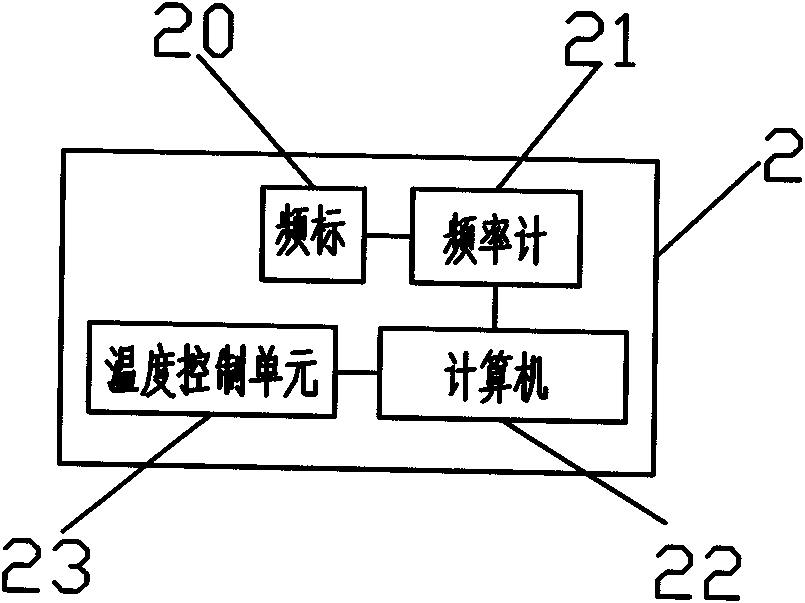

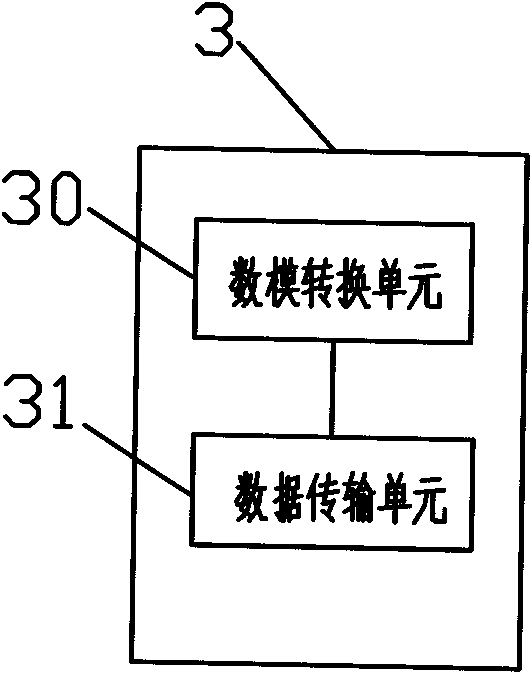

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As above, please refer to figure 1 The automatic test system 100 of the temperature compensated crystal oscillator of the present invention includes a power supply 1, a temperature box 5, a data transmission module 3, a central control module 2 and a crystal oscillator gating module 4, and the power supply 1 supplies the temperature box 5, the The data transmission module 3 and the central control module 2 supply power, the incubator 5 houses a plurality of crystal oscillators 410 to be tested, and the central control module 2 controls the temperature of the incubator 5 . Among them, please refer to figure 2 and image 3 , the central control module 2 includes a computer 22, a frequency standard 20, a frequency meter 21 and a temperature control unit 23, and the frequency meter 21 is electrically connected to the frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com