Piano keyboard coupling type glass slice board falling device

A glass and shaft connection technology is applied in the field of production equipment for the cold end of float glass, which can solve the problems of increased processing cost, and achieve the effect of reducing structural cost and simplifying and rationalizing the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

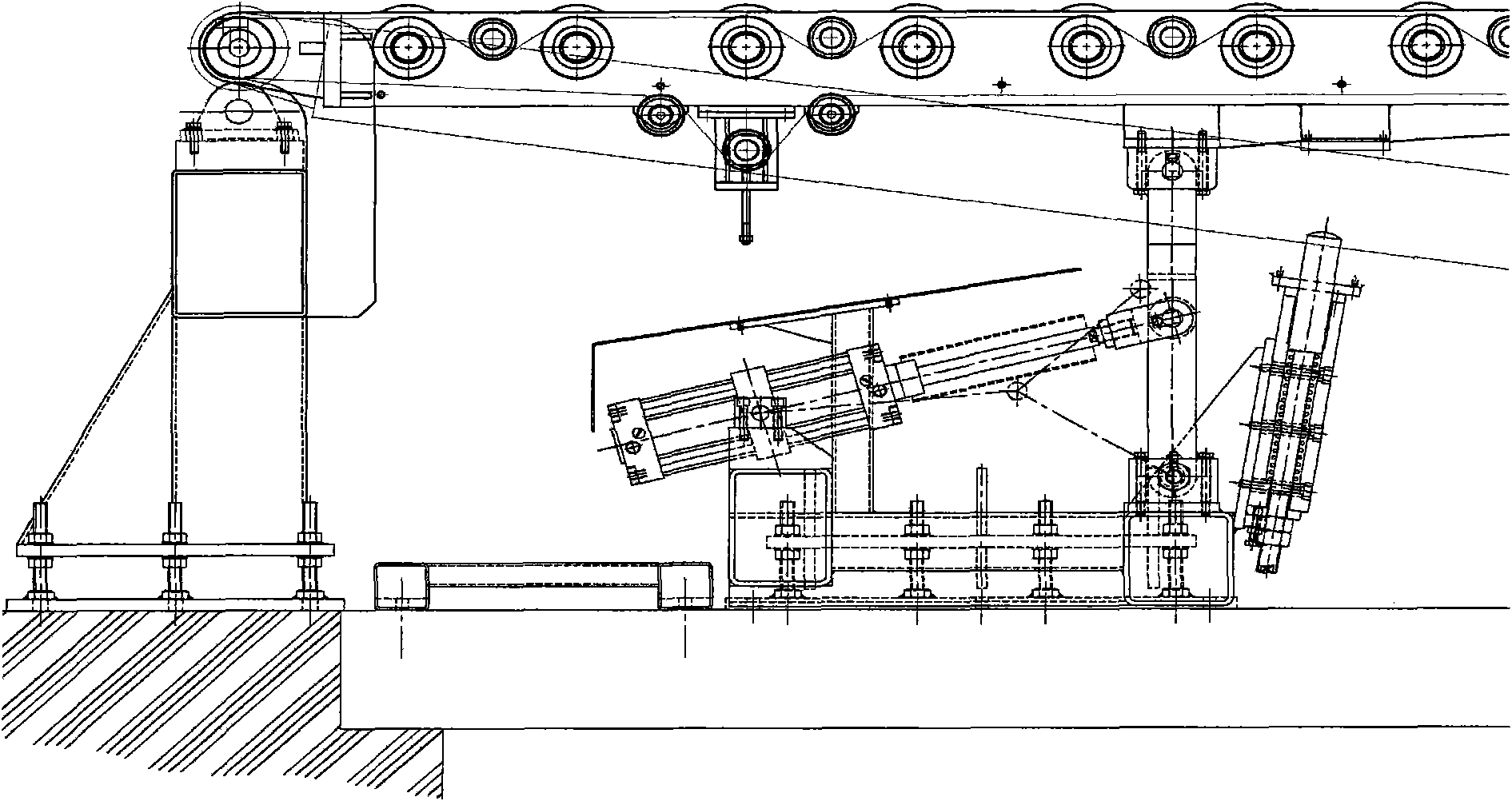

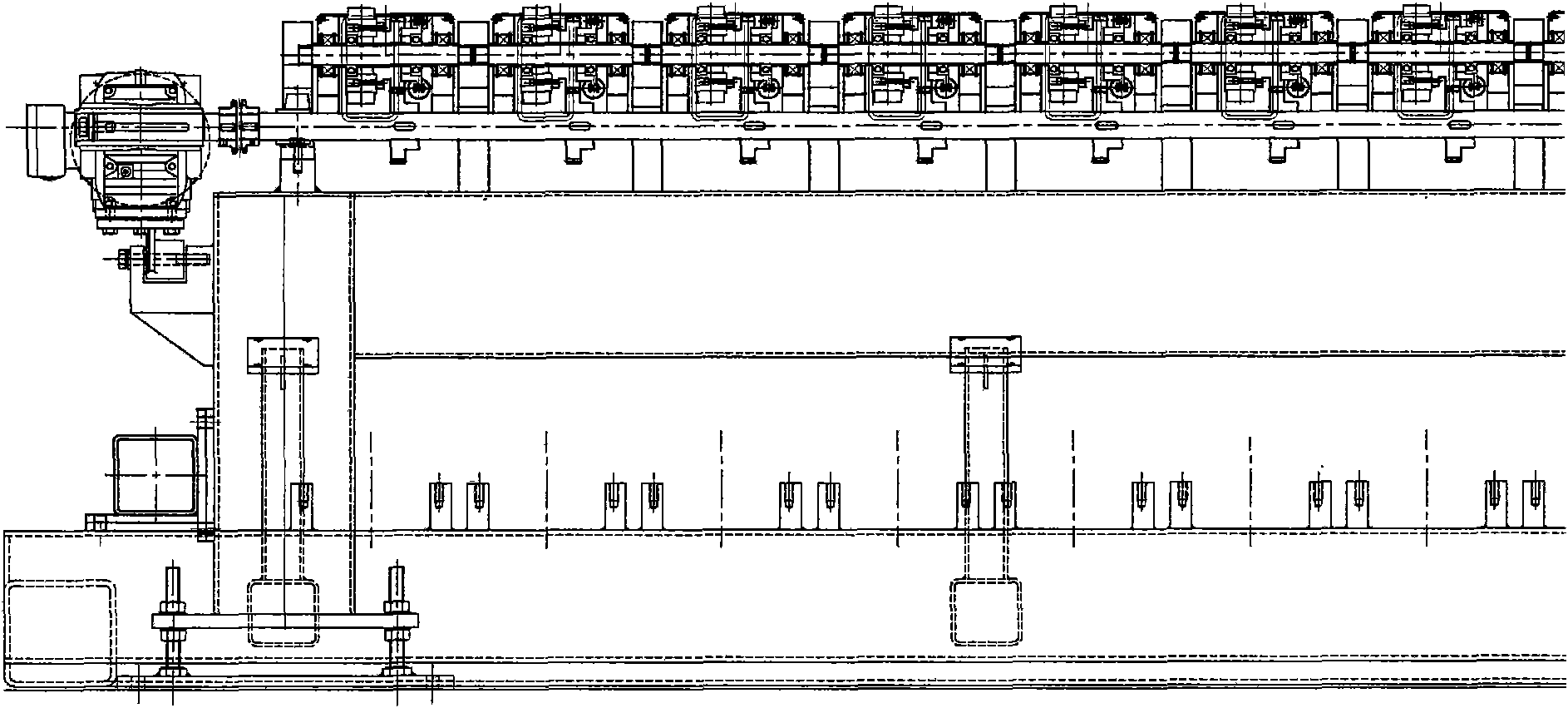

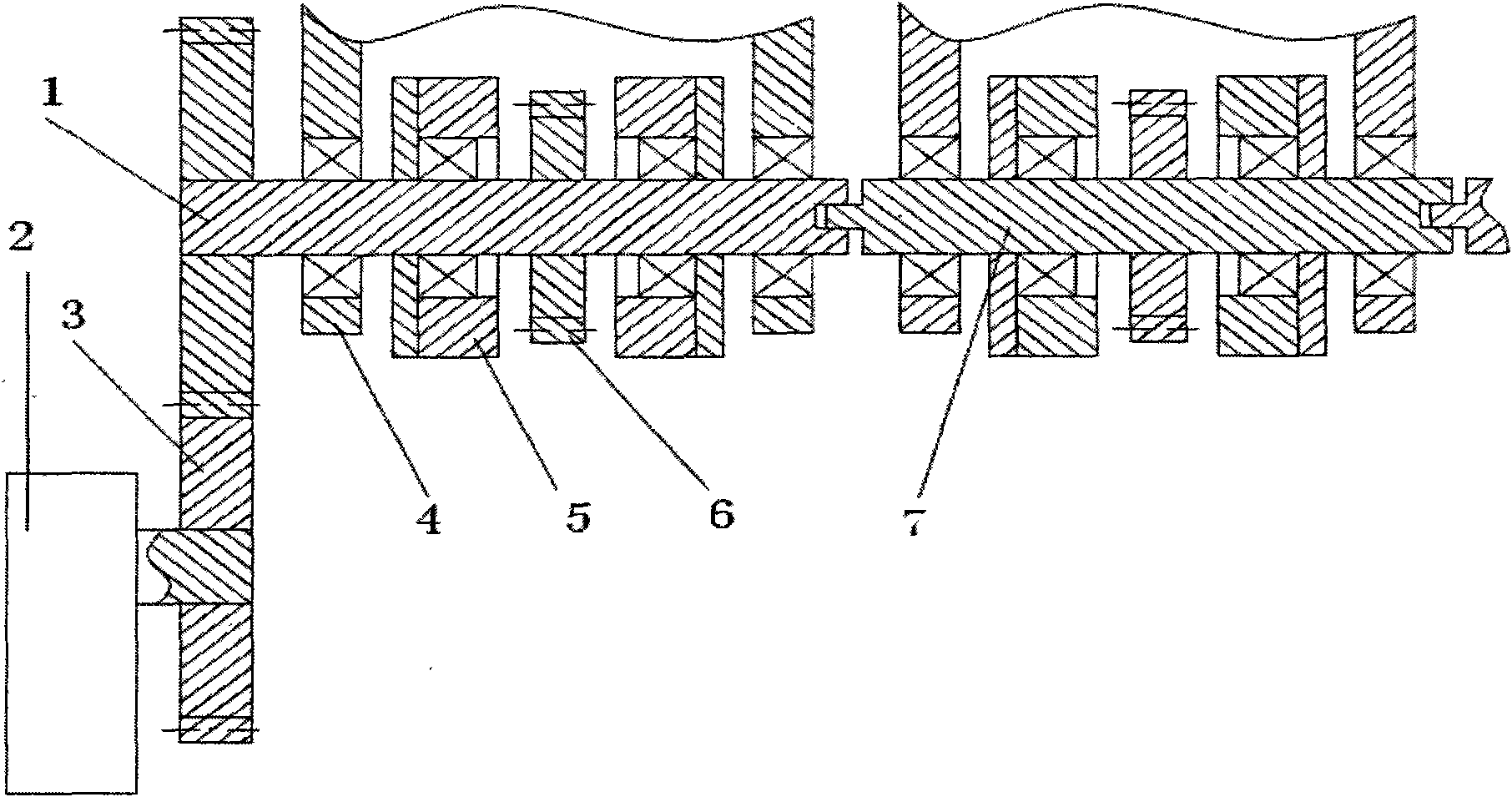

[0012] The structure of the present invention comprises a frame, a swing arm mechanism, a lifting mechanism and a motor transmission mechanism (2), and the lifting mechanism is composed of a cylinder, a crank and a buffer device, and is characterized in that each swing arm has a separate transmission shaft (7), The two ends of each unit transmission shaft (7) are fitted on a bearing fixed on the frame bearing seat (5), and a sprocket (6) is fixed on the unit transmission shaft (7), and the swing arm (4) moves Mounted on the unit transmission shaft (7), a swing arm (4) and a lifting mechanism are connected separately to form a glass falling unit, and the first unit transmission shaft (1) adjacent to the transmission mechanism extends out from the left end of the transmission mechanism. Bearing seat (5), the shaft end of which is fixed with a gear, which meshes with the output gear (3) of the electric transmission mechanism fixed on the frame, and the right end of the first unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com