Anti-collision control method of fixture

A control method and anti-collision technology, which is applied in the direction of clamping, manufacturing tools, grinding machine tool parts, etc., can solve problems such as collisions, affecting product accuracy, and equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

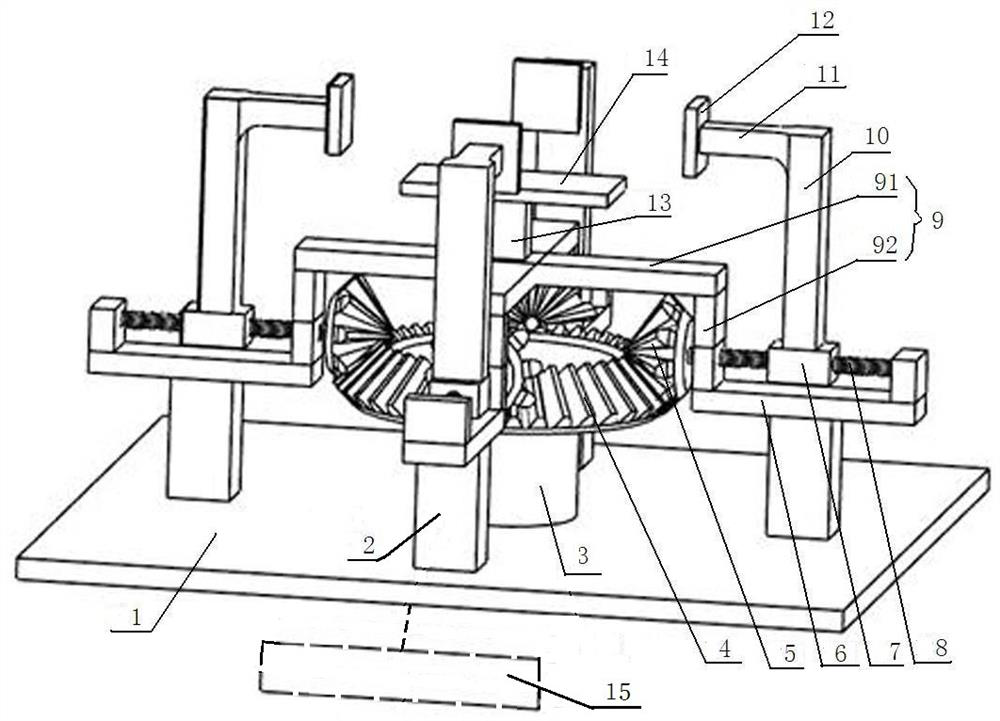

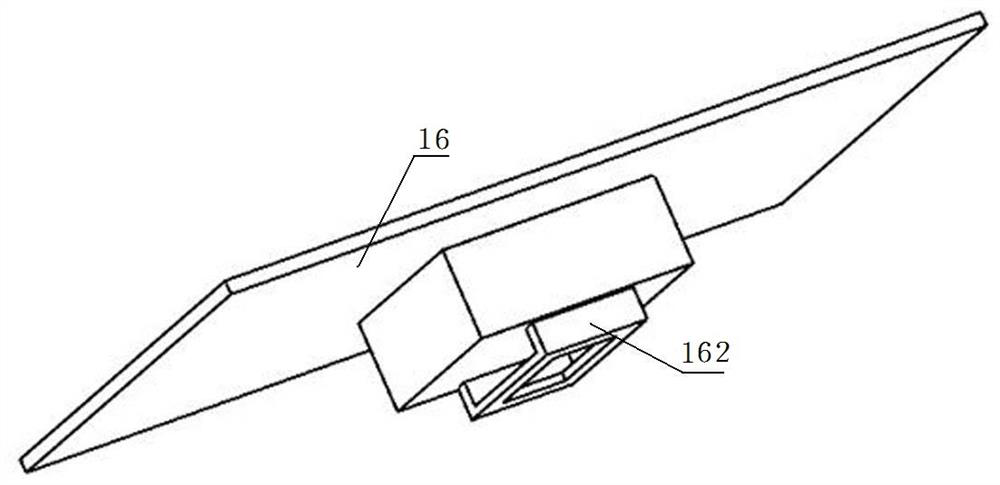

[0028] figure 1 , figure 2 The shown multi-directional anti-collision fixture includes a conical bull gear 4 arranged on the installation base 1 and a bracket 9 spanning above the conical bull gear 4, and an enclosure between the installation base 1 and the conical bull gear 4 is provided. To the bevel gear drive motor 3 in the middle of the support foot 2, the bevel gear 4 is meshed with two pairs of bevel pinion gears 5; each pair of bevel pinion gears 5 is relatively arranged; wherein, the support 9 includes two cross bars 91 and Four vertical rods 92 protruding downward from the two ends of the respective cross rods 91; the vertical rods 92 are connected with the respective screw bases 6; The screw shafts 8 of the respective conical pinions are provided on the screw bases 6, and each conical pinion 5 is set on one end of the respective screw shaf...

Embodiment 2

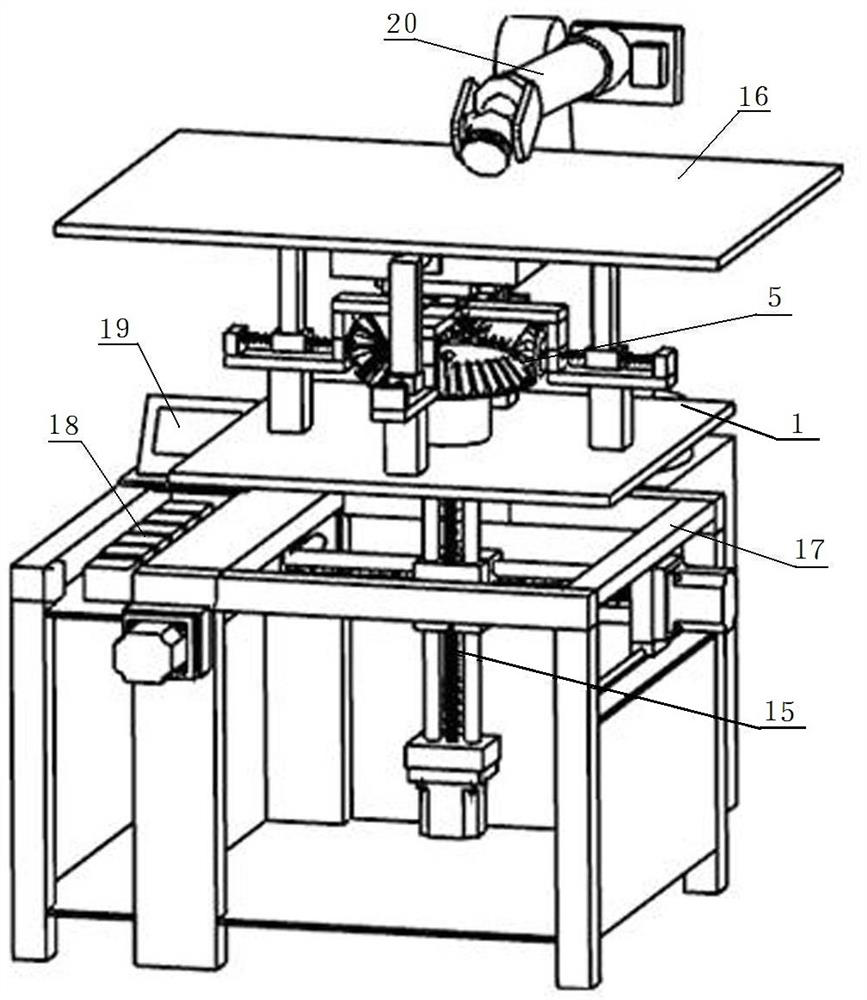

[0035] Such as Figure 6 As shown, the driving device includes an X-direction rack 251 meshing with an X-direction gear 254, a Y-direction rack 252 meshing with a Y-direction gear 255, and a Z-direction rack 253 meshing with a Z-direction gear 256; There are two racks 252 parallel to each other, and the two Y racks 252 are installed on the frame through their respective Y rack seats; a mounting plate 250 for the X racks is arranged between the Y racks 252, The mounting plate 250 is provided with a long through hole for wearing the Z-direction rack 253 in the same direction as the X-direction rack 251; the top of the Z-direction rack 253 is fixedly connected to the mounting base plate of the fixture; the drive motor includes an X-direction gear drive motor 257. The Y-direction gear drive motor 258 and the Z-direction gear drive motor 259; the output shaft of the X-direction gear drive motor 257 is set on the core hole of the X-direction gear 254, and the output shaft of the Y-d...

Embodiment 3

[0038] Such as Figure 7 As shown, the driving device is the mechanical arm 331 of the robot, and the hand joint of the mechanical arm is fixedly connected with the installation base plate of the fixture; the operating claw 332 of the robot is connected with the mounting plate of the object to be clamped; the controller is located in the robot body; the driving motor is The mechanical arm drive motor; the signal output end of the PLC programmable control module is respectively connected with the mechanical arm drive motor through the second drive module; all the others are the same as the first embodiment;

[0039] Its anti-collision control method is: when the real-time signals sensed by the horizontal anti-collision sensor and the vertical anti-collision sensor exceed the preset value in the controller, it means that the clamped operating claw is collided in an oblique direction. At this time, the controller will After the received signal is judged and processed, the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com