Manipulator collision prompting device

A technology of manipulators and warning devices, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inability to grade warnings and collisions that cannot serve as warnings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

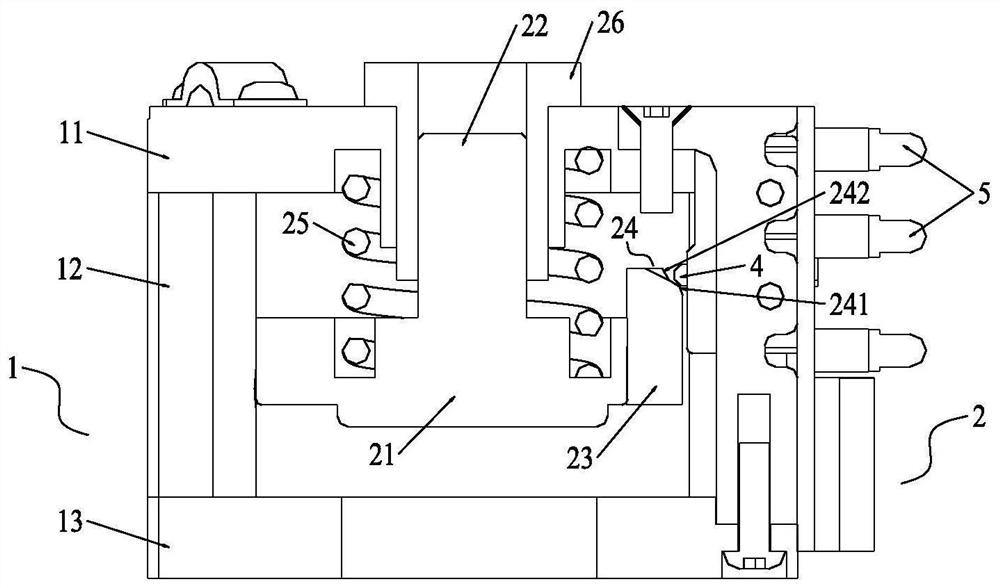

[0030] A kind of manipulator collision warning device, see figure 1 , including a frame 1 and an anti-collision assembly 2 arranged in a support mechanism, the frame 1 includes an upper panel 11, a lower panel 13 and a fixed column 12 arranged between the upper and lower panels 13, the fixed column 12 It is used to fixedly connect the upper and lower panels 13 to form a rectangular frame. The anti-collision assembly 2 is arranged in the cavity surrounded by the rectangular frame. The anti-collision assembly 2 includes a support plate 21 fixed to the top of the support plate 21. The connected slide bar 22 and the pressing plate 23 fixed on the edge of the support plate 21, the top end of the slide bar 22 is located in the frame 1 and is slidingly fitted with the frame 1, the outside of the slide bar 22 A spring 25 is sleeved, and the two ends of the spring 25 abut against the frame 1 and the support plate 21 respectively. Specifically, the center of the upper panel 11 is provid...

Embodiment 2

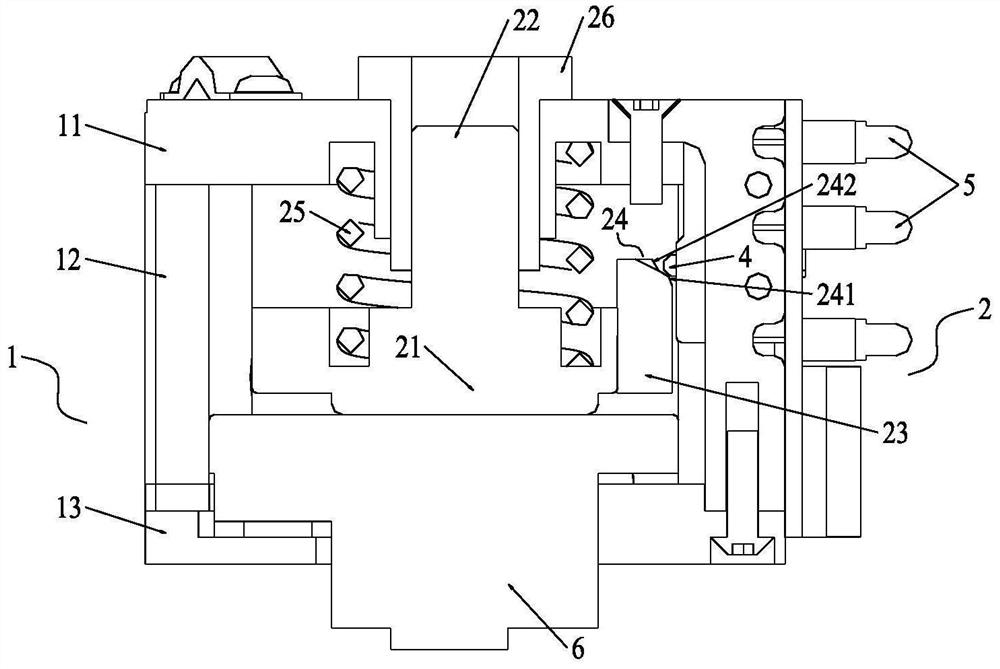

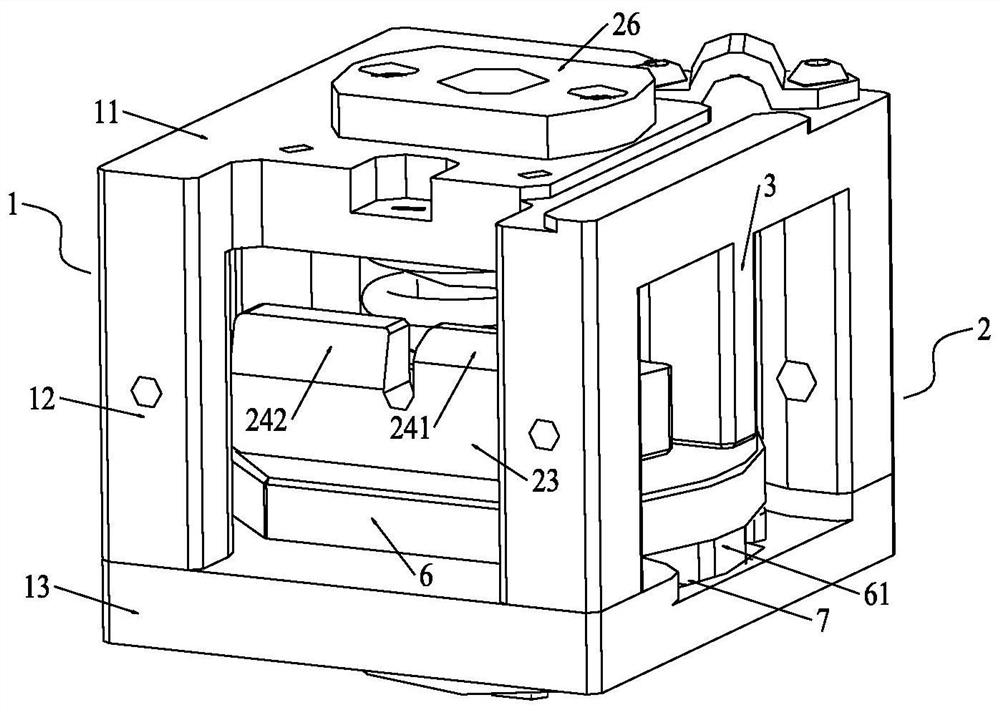

[0034] Embodiment 2 is basically the same as Embodiment 1, and its difference is: see Figure 2-6 A T-shaped movable plate 6 rests between the lower panel 13 of the frame 1 and the support plate 21, and the lower end of the movable plate 6 passes through the bottom of the frame 1 and can rotate relative to the frame 1 , the lower end of the movable plate 6 is connected to a power load. That is, the movable plate 6 is located below the support plate 21 and rests on the lower panel 13, the lower end of the movable plate 6 protrudes from the lower panel 13 and is rotatably connected with the lower panel 13, Therefore, the movable plate 6 can move up and down and deflect vertically relative to the lower panel 13 and the support plate 21 . In order to prevent the movable plate 6 from deflecting excessively, a fan-shaped groove 7 is formed on the lower panel 13 of the frame 1, and a fan-shaped protrusion 61 matching the shape of the groove is formed on the bottom of the movable pla...

Embodiment 3

[0038] Embodiment 3 is basically the same as embodiment 1 or embodiment 2, and its difference is: see Figure 7 A plurality of the contact switches 4 are vertically distributed side by side, and at this time, the pressing plate 23 may only have one inclined surface 24 . By being arranged side by side, the distances between a plurality of the contact switches 4 and the inclined surface 24 are different, and the moving distance of the pressing plate 23 is related to the collision force. Therefore, different warning devices are respectively activated by pressing the moving distance of the pressing plate 23. 5. Realize hierarchical touch warning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com