Three-in-one press sleeving machine tool of sleeving lock

A three-in-one, lock technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of damage to the lock sleeve, difficult positioning, slow work efficiency, etc., to eliminate accumulated errors and deformation, reasonable and simplified structure, The effect of reducing the processing link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

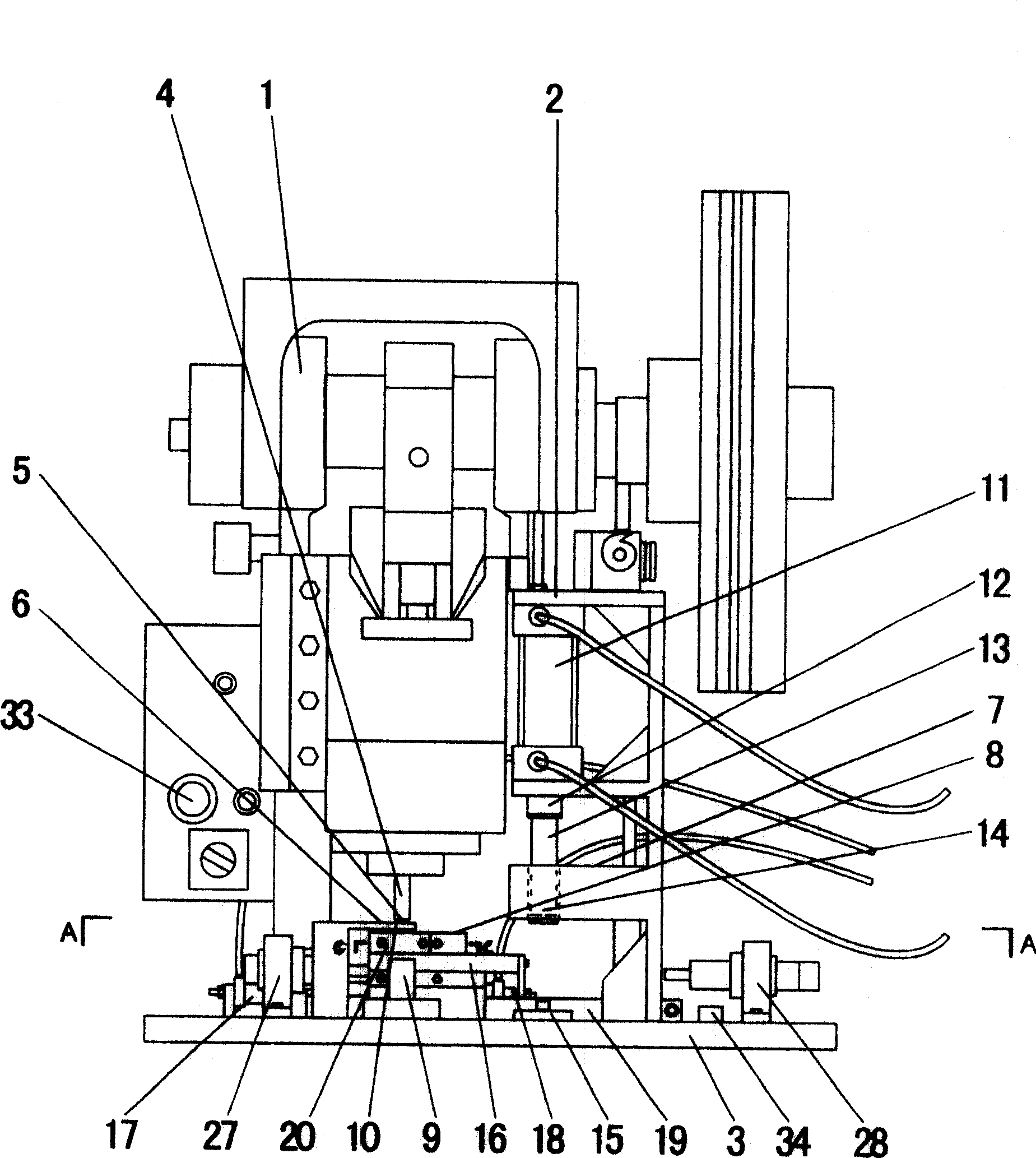

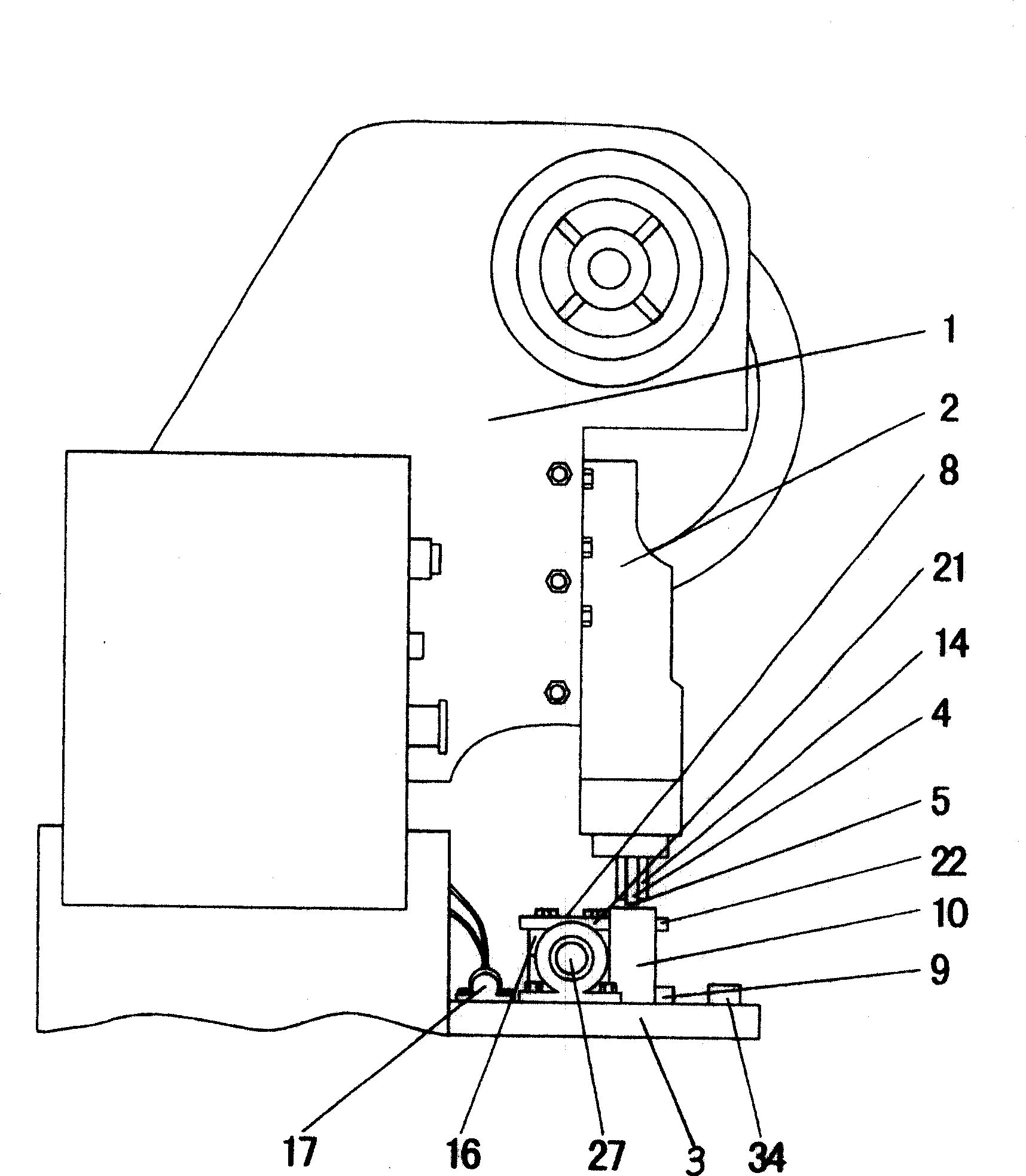

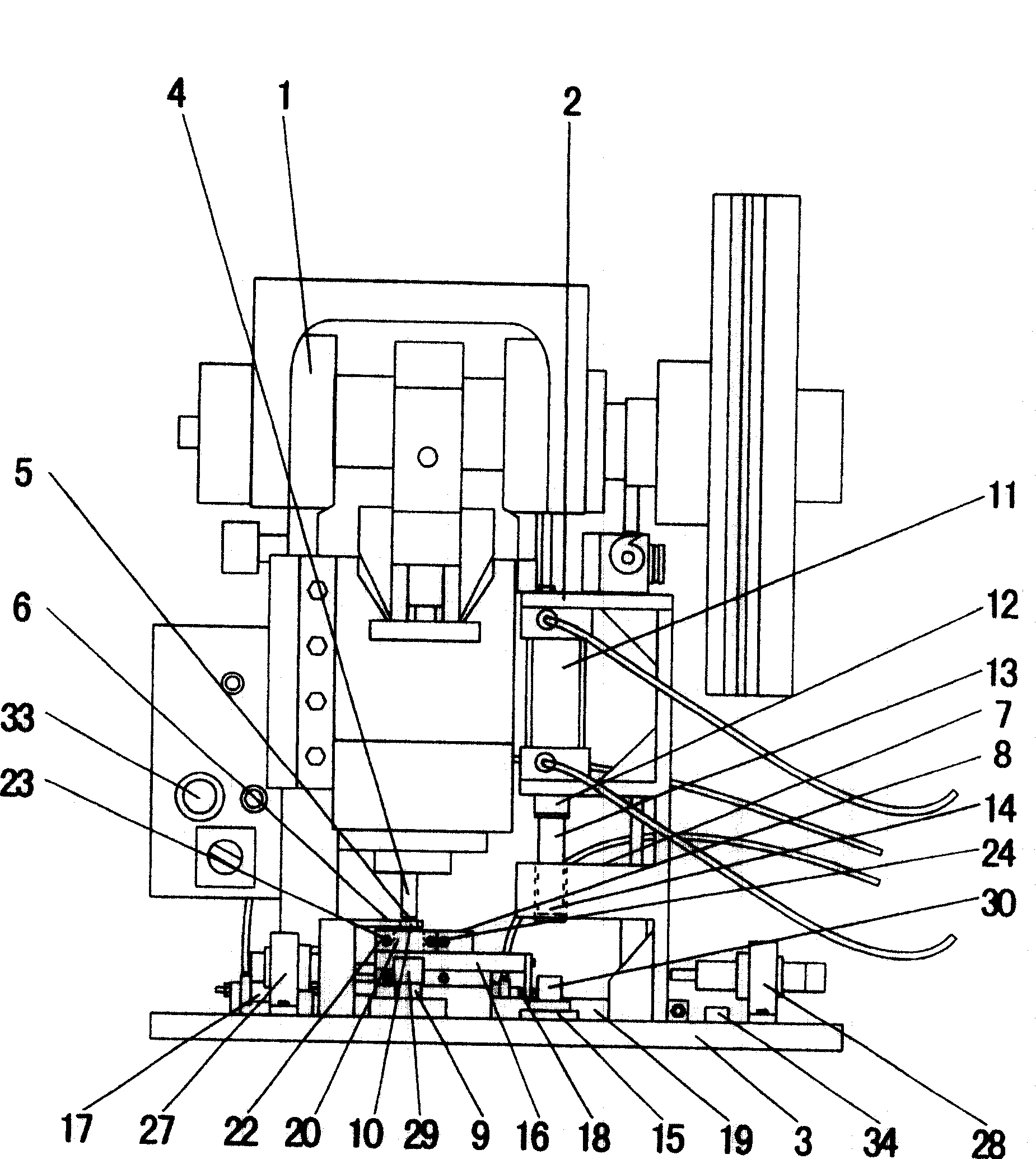

[0021] Depend on Figure 1-9 Represented is an embodiment of the present invention, and it comprises punching machine 1, punching bed bed 2, punching machine platform 3, punch head 4, trademark die 5, on the punching machine platform 3, the punching box casing punching trademark mechanism 6 is housed, the punching machine The platform 3 and the punch bed 2 are equipped with a lock casing lock body riveting mechanism 7 , and the punch platform 3 is equipped with a lock casing clamping and station displacement mechanism 8 . The lock sleeve shell punching and marking mechanism 6 is the position corresponding to the punch head 4, and the punching die 9 and the discharge baffle 10 of the lock sleeve shell 29 are installed on the punch platform 3; the lock sleeve shell lock body riveting mechanism 7 is The punch bed 2 is also equipped with a cylinder 11, the cylinder piston rod 12 is equipped with a riveting punch 13, the punch bed 2 is also equipped with a guide sleeve 14 for rivet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com