Metal digital printing method and metal printing plate

A digital printing and printing plate technology, applied in the field of metal surface printing, can solve the problems of high printing cost and poor printing effect, and achieve the effect of saving the cost of repeated printing and cleaning, good printing effect and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

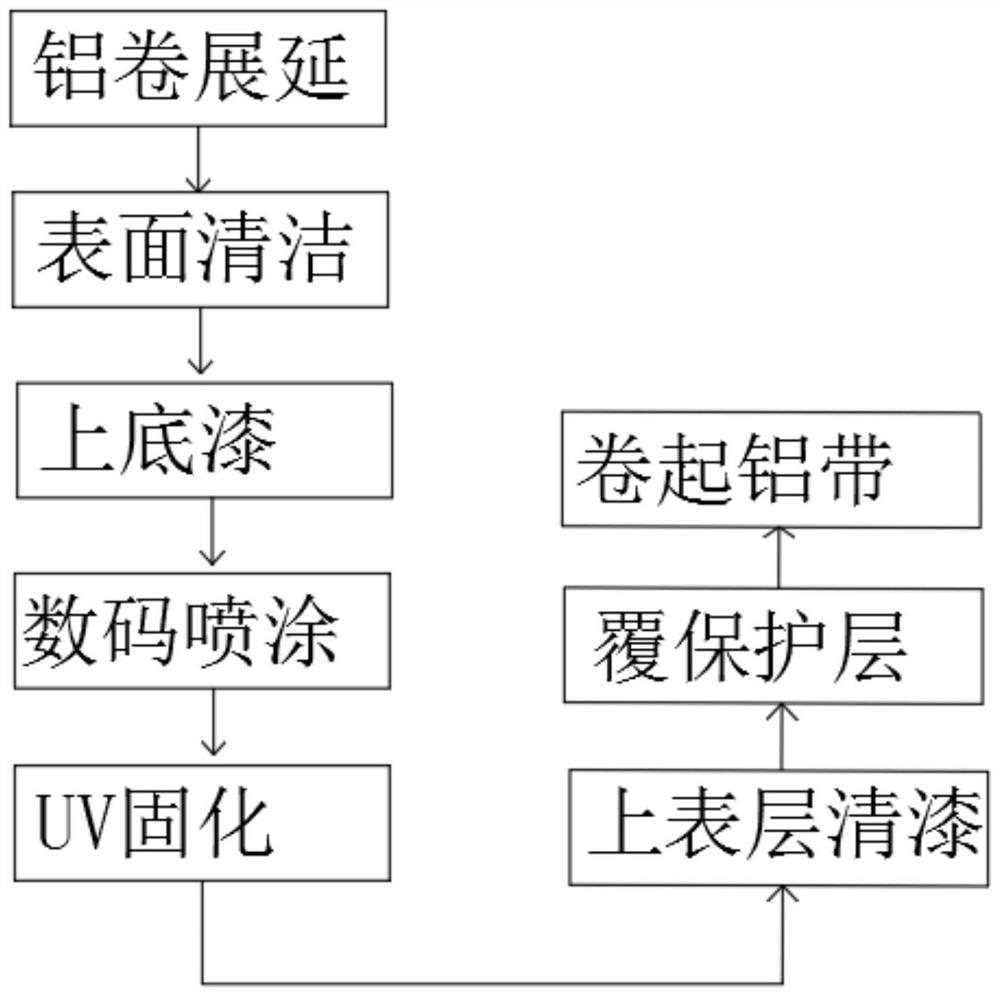

[0043] Combine below Figure 1 to Figure 2 As shown, the embodiment of the present invention provides a metal digital printing method, the method includes the following steps:

[0044] Sp1: Automatically spread the aluminum coils and transfer the unrolled aluminum coils to the clean room;

[0045] Sp2: Clean the aluminum coil in the clean room to remove impurities and dust on the surface of the aluminum coil;

[0046] Sp3: primer on the surface of the aluminum coil;

[0047] Sp4: On the primer on the surface of the aluminum coil, use a digital printer to spray;

[0048] Sp5: The printed aluminum coil is cured by UV light;

[0049] Sp6: Cover the protective layer on the surface of the printing layer;

[0050] Sp7: Roll up the track, wrap and transport in sequence.

[0051] In this embodiment, metal digital printing technology is used to produce printing plates. Different from traditional roller coating printing and lamination, metal printers use computer software to contro...

specific Embodiment 2

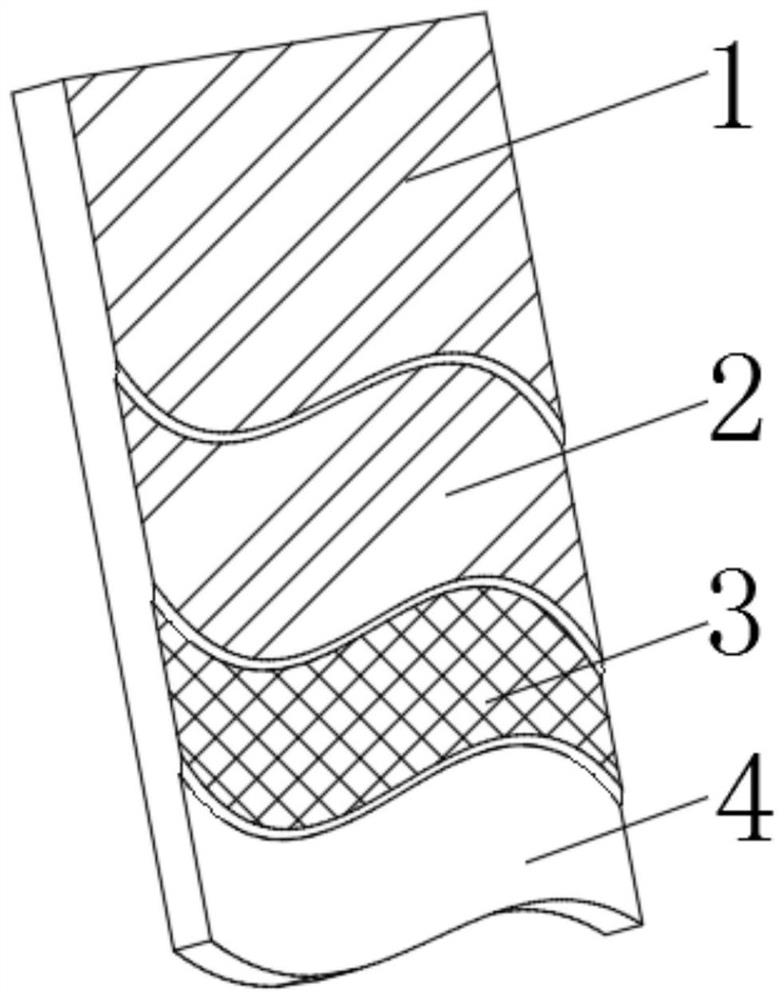

[0058] A metal printing plate obtained by a metal digital printing method. The metal printing plate includes a metal layer 4, a conventional cured primer layer 3, a UV ink layer 2, and a conventional cured varnish protective layer 1 sequentially from the bottom up.

[0059] Specifically, the metal layer 4 is made of steel or aluminum as the base layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com