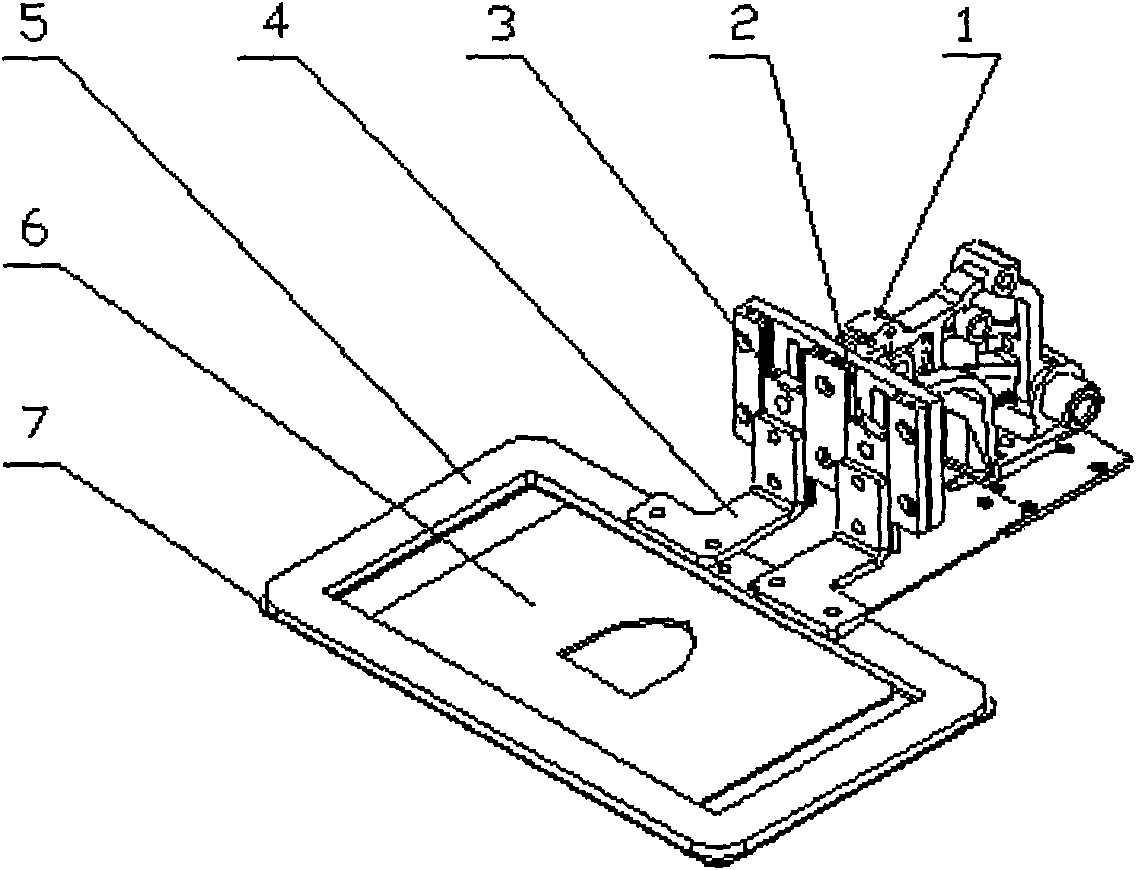

Press material structure of pattern sewing machine

A pattern machine and pressing plate technology, which is applied in the direction of cloth pressing mechanism, cloth feeding mechanism, sewing machine components, etc., can solve the problems of no pressing, easy to move, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

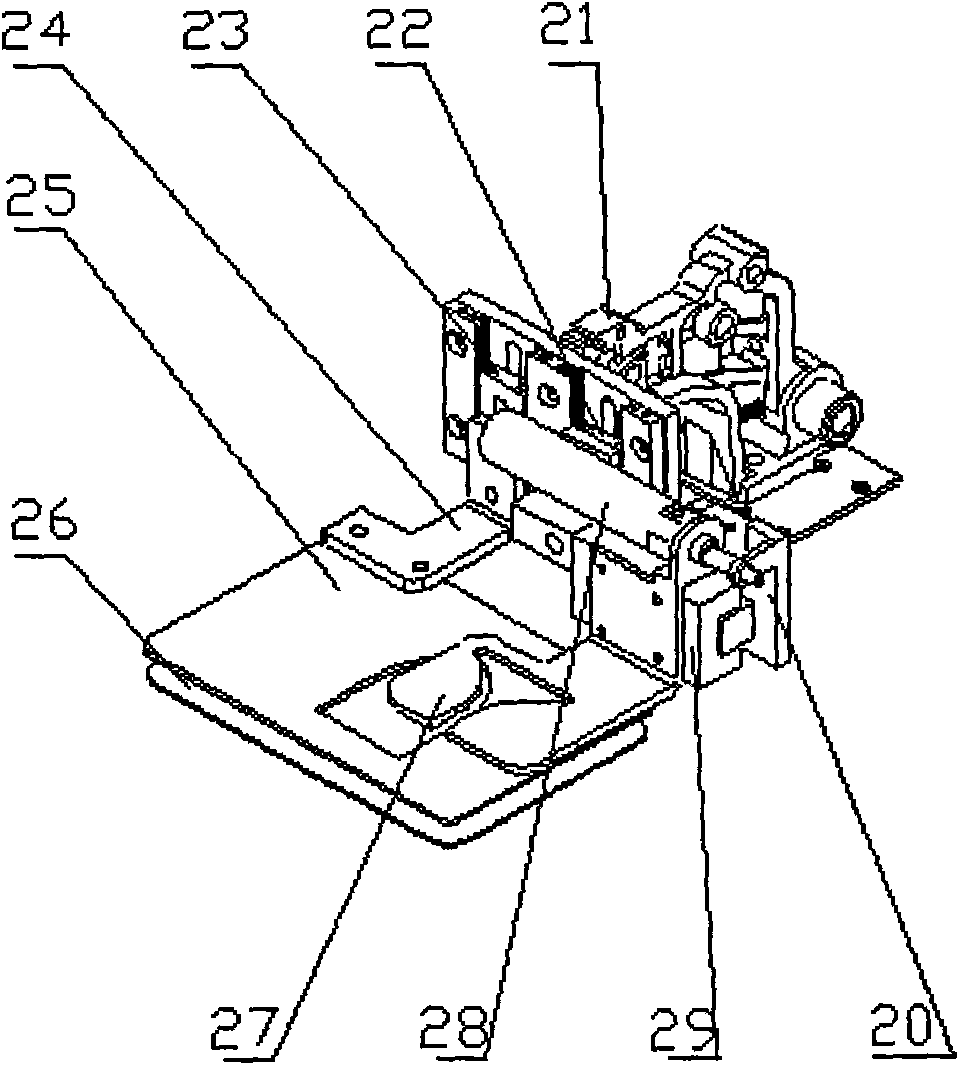

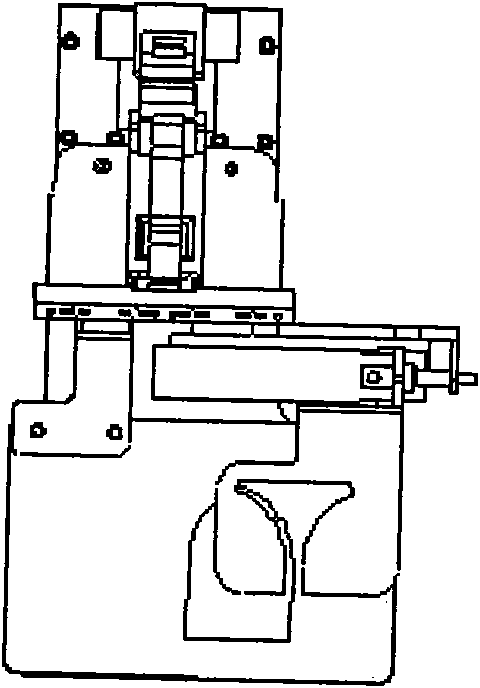

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0013] Depend on figure 2 Visible: the present invention comprises: bracing frame 21; The right slide rail 22 that is connected on the bracing frame 21 and the left slide rail 23; Outer pressure plate 25 is connected with left slide rail 23 by connecting plate 24; Move up and down by left slide rail 23 , press the sewing material on the pallet 26; also include: the middle pressure plate 27 and the line rail assembly 29 arranged on the outer pressure plate 25; the middle pressure plate 27 and the line rail assembly 29 are connected; the line rail assembly 29 is connected through the right The plate 20 is connected with the right slide rail 22; the sewing material is pressed on the pallet 26 by moving the right slide rail 22 up and down; and the cylinder 28 between the right connecting plate 20; the cylinder 28 can make the middle pressure plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com