Ring cooling machine rocking shaft adjusting and fixing device

The technology of a fixing device and a rocker arm shaft is applied in the field of the adjusting and fixing device of the rocker arm shaft of a ring cooler, which can solve the problems of increased grate plate gap, uneven grate plate of the trolley, and leakage of pellets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

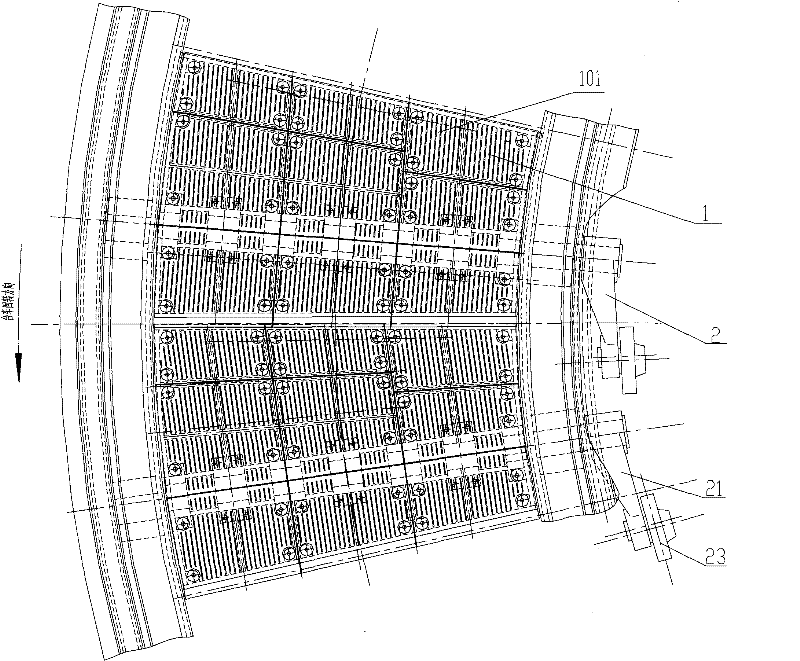

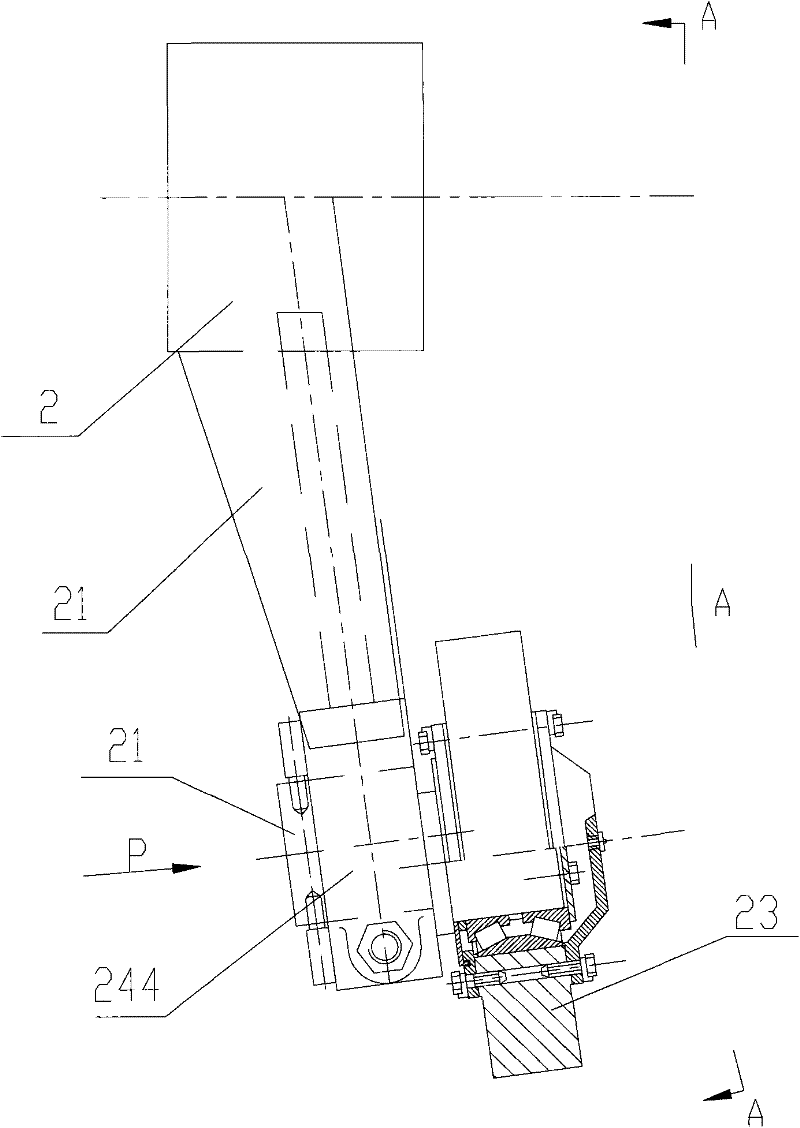

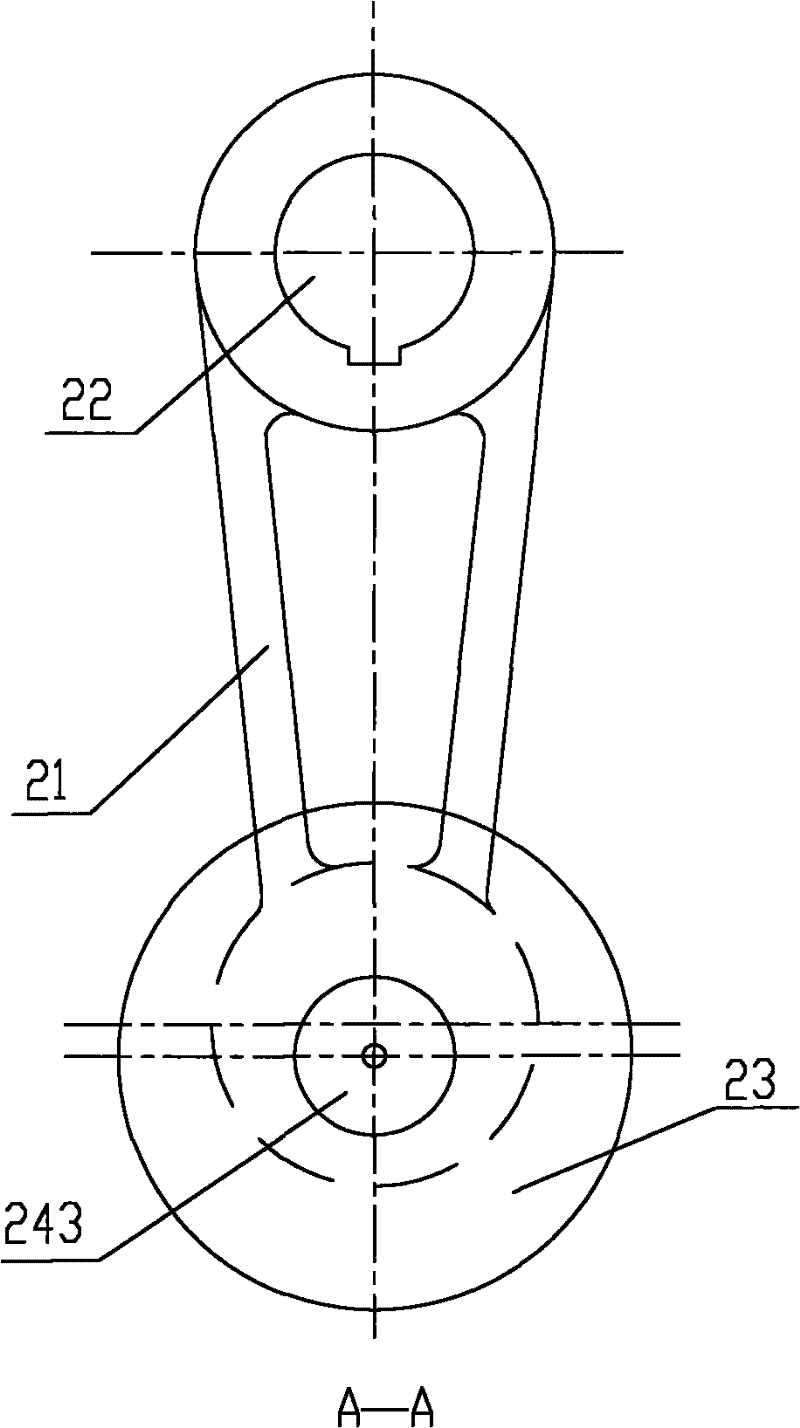

[0025] In order to facilitate the understanding of those skilled in the art, first combine figure 1 , to specifically illustrate the working principle of the trolley grate plate of the annular cooler described in the embodiment.

[0026] see figure 1 , which is the front view of the trolley grate plate of the annular cooler according to the embodiment of the present invention.

[0027] The grate plate of the trolley of the annular cooling machine in the embodiment of the present invention makes the grate plate 1 in a horizontal state through the rocker device 2 . figure 1 The direction indicated by the arrow is the running direction of the annular cooler.

[0028] Due to the unevenness of the grate plate 1 of the trolley during the installation of the trolley of the annular cooler, the gap between the grate plates 1 increases, resulting in material leakage of the pellets.

[0029] The invention provides an adjusting and fixing device for a rocker shaft of an annular cooler,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com