Radiator and manufacturing method thereof

A manufacturing method and radiator technology, applied in the direction of instruments, instrument cooling, instrument parts, etc., can solve the problems of poor convection heat dissipation effect and unsatisfactory heat dissipation effect, so as to prevent heat retention, strengthen convection heat dissipation effect, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

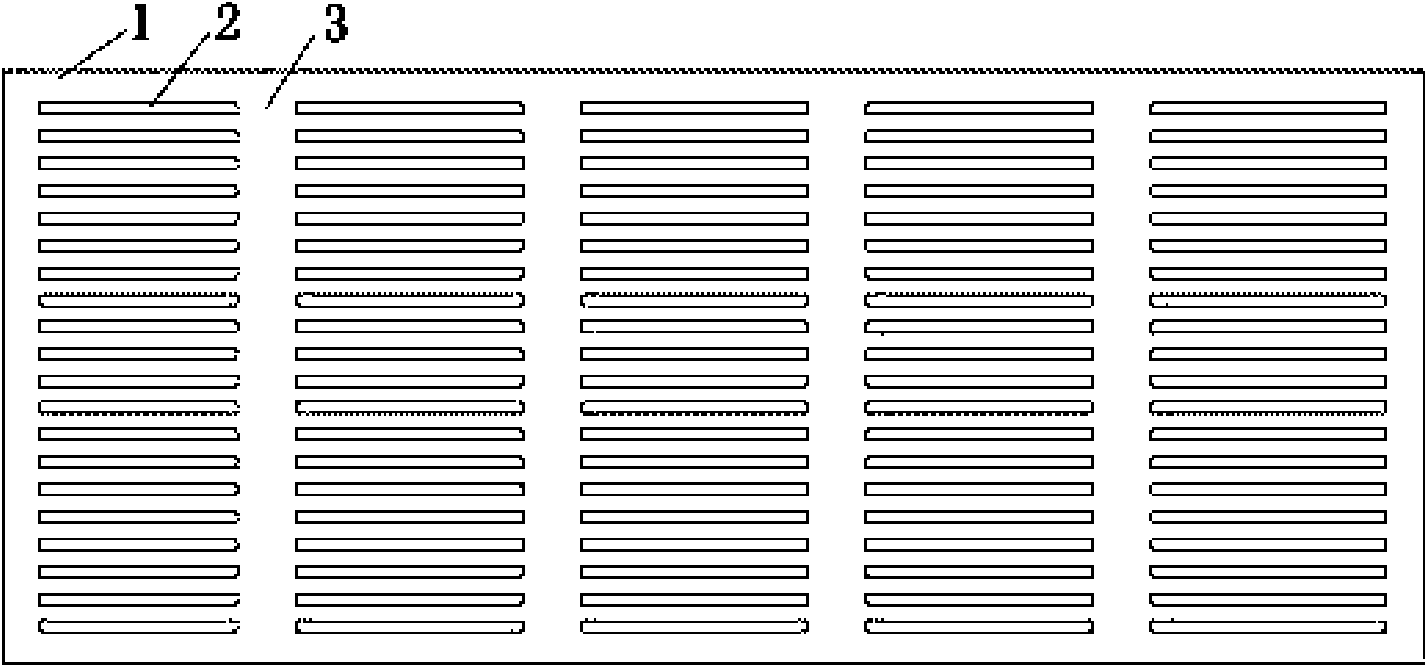

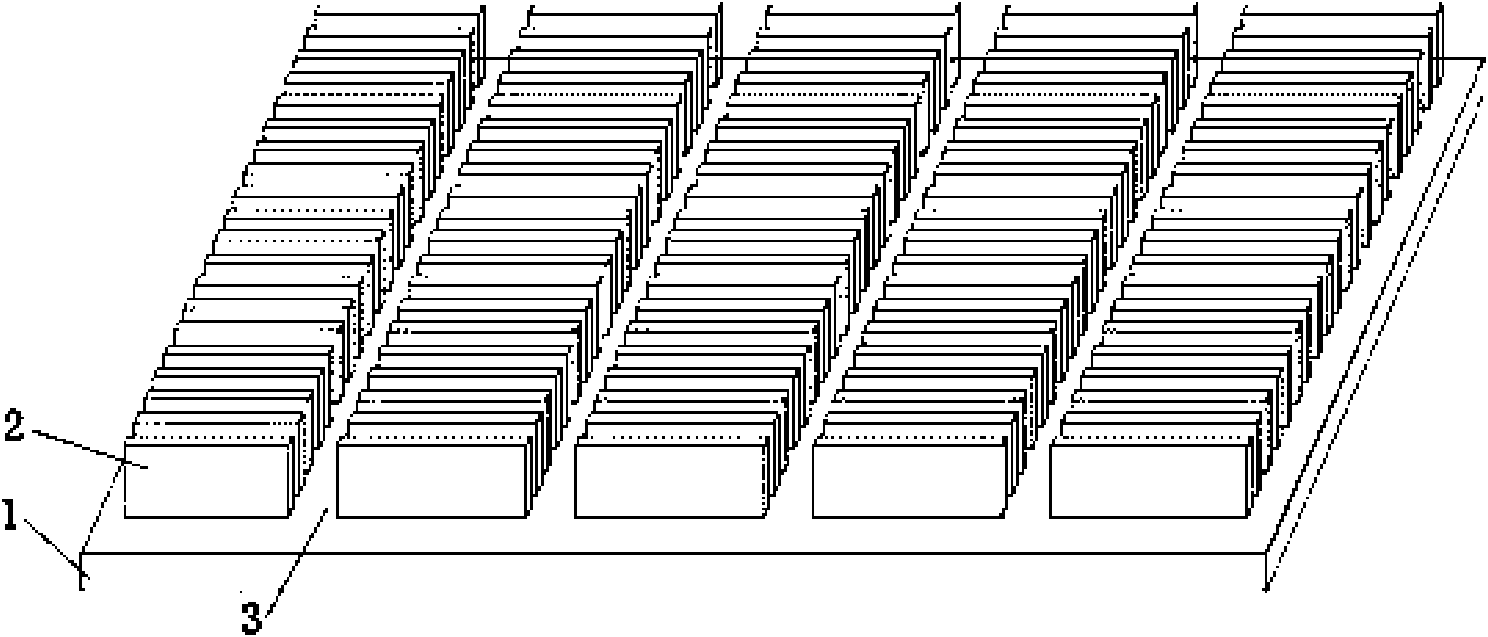

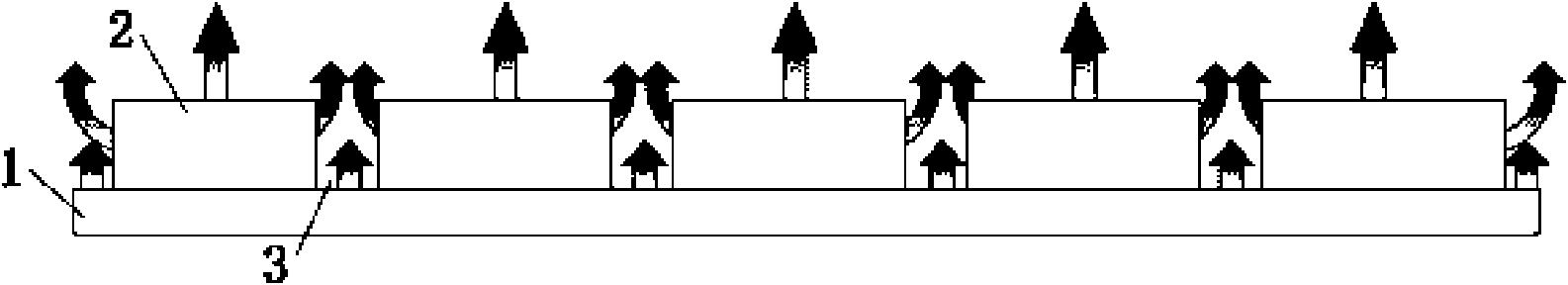

[0014] Example. Such as figure 1 , figure 2 As shown, the radiator of the present invention includes a radiator base 1 and cooling fins 2 , and the cooling fins 2 are fixedly mounted on the radiator base 1 . A convection groove 3 is provided between two adjacent groups of heat dissipation fins 2. The convection groove 3 divides the heat dissipation fins 2 into several sections, forming a certain convection space between the heat dissipation fins 2, which is beneficial to the heat dissipation of the heat dissipation fins. 2 convection heat dissipation, the thermal diagram is shown in image 3 shown. Depending on the arrangement of the heat dissipation fins 2, the convection grooves 3 can be horizontal grooves or longitudinal grooves, that is, when the heat dissipation fins 2 are arranged horizontally, the convection grooves 3 are longitudinal grooves; When the fins 2 are arranged vertically, the convection grooves 3 are horizontal grooves.

[0015] During manufacture, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com